Cosmetic product bottling device capable of achieving continuous feeding

A technology for filling equipment and cosmetics, which is applied in packaging, liquid bottling, bottle filling, etc. It can solve the problems of dripping residual liquid at the discharge port, polluting the working environment, and spilling liquid, so as to prevent liquid dripping and protect cleanliness , the effect of preventing liquid from spilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]In order to enable those in the technical field to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying drawings in the embodiments of the present invention.

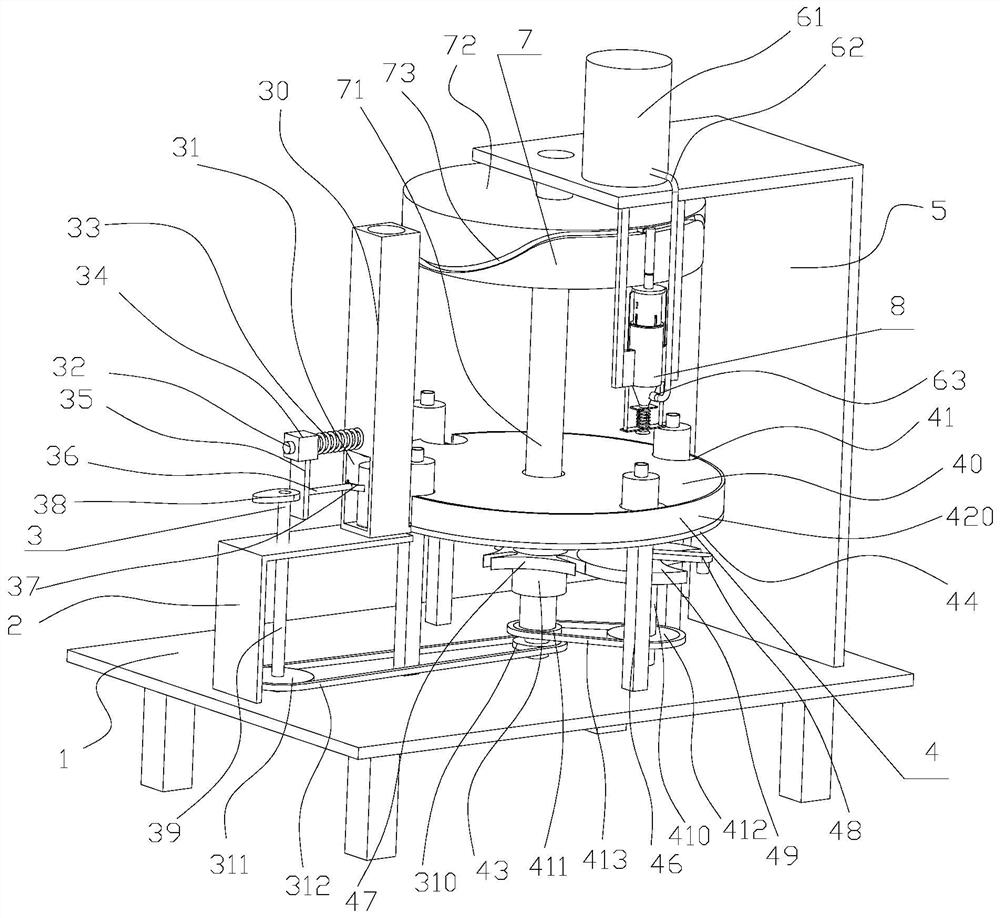

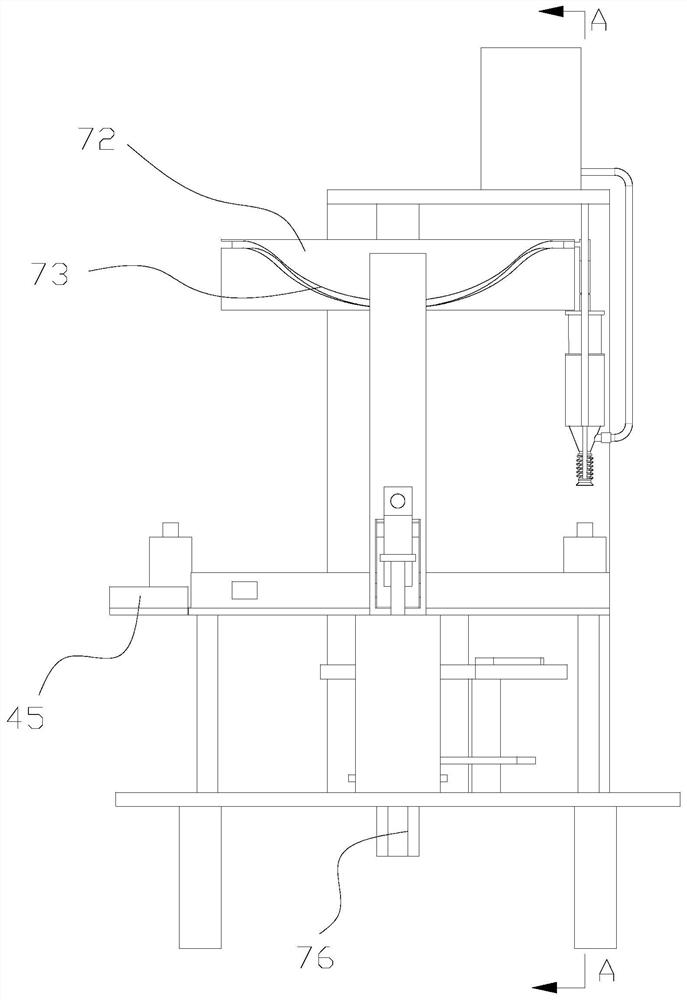

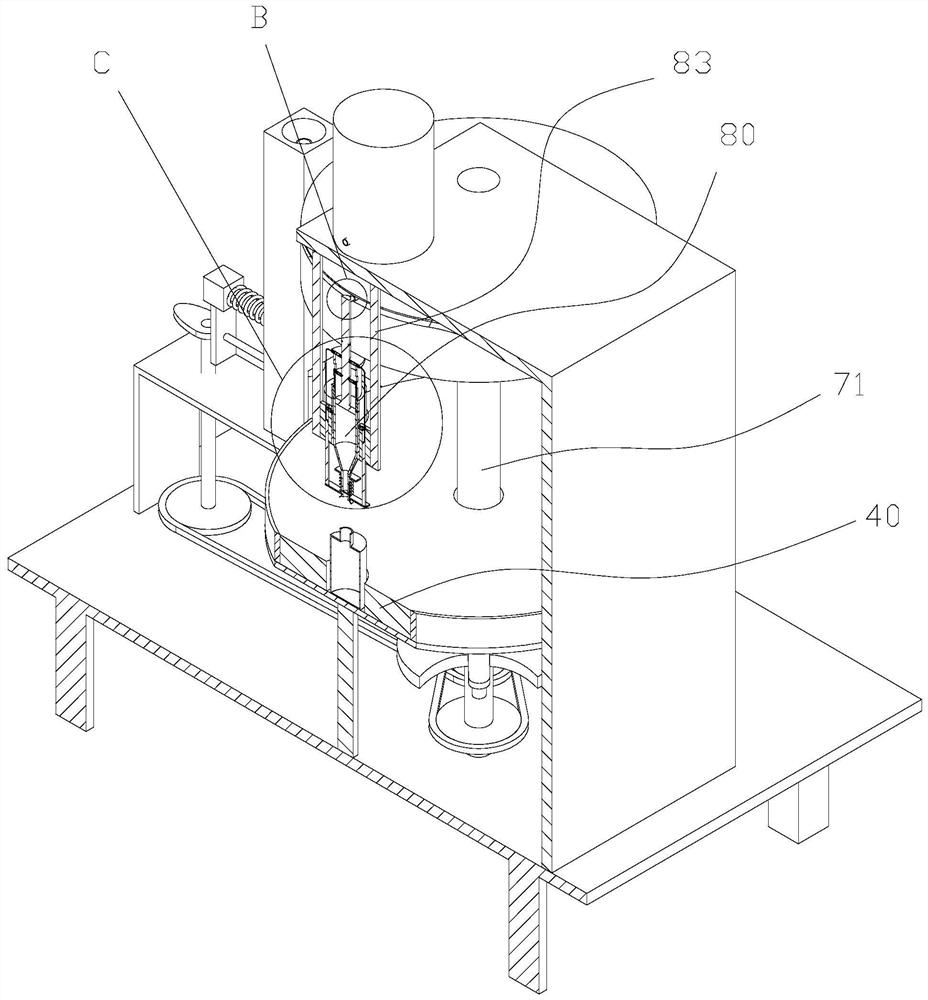

[0029]Such asFigure 1-14 As shown, a cosmetics filling equipment capable of continuous injection includes a base 1, a first L-shaped plate 2, a feed assembly 3, a station switching component 4, a second L-shaped plate 5, a storage tank 61, Feed pipe 62, one-way valve 63; the first L-shaped plate 2 is fixed above the base 1; the feed assembly 3 is provided on the first L-shaped plate 2; the station switching The component 4 is arranged on the right side of the feed assembly 3; the second L-shaped plate 5 is fixed on the upper right of the base 1; the storage tank 61 is fixed above the second L-shaped plate 5; The feed pipe 62 is a hose and communicates with the storage tank 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com