High-performance glass fiber ingredient and glass fibers prepared from same

A glass fiber, high-performance technology, applied in the field of high-performance glass fiber ingredients and glass fibers prepared, can solve the problems of increased glass fiber cost, difficulty in preparing high-performance glass fibers, and high price of rare earth oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4 and comparative example 1-2

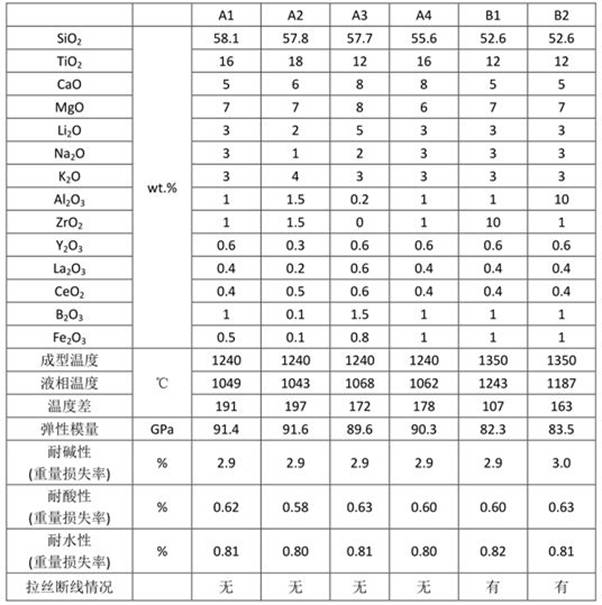

[0040] The corresponding glass fibers were prepared with reference to the composition ratio in Table 1. Examples 1-4 are respectively marked as A1-A4, and comparative examples 1-2 are marked as B1-B2.

[0041] In the performance test and comparison, the liquidus temperature, molding temperature, temperature difference between molding temperature and liquidus temperature, elastic modulus, alkali resistance, acid resistance and water resistance of the glass fiber ingredients and the glass fibers prepared are listed , Drawing wire breakage, see Table 1 for specific results.

[0042] Table 1

[0043]

[0044] As can be seen from the specific results in the above table, when using a high content of TiO 2 At the same time, the use of very low content of Al 2 o 3 and ZrO 2 The blockage of the orifice plate can be avoided, thereby avoiding the occurrence of wire breakage during the wire drawing forming process. High content of TiO 2 The use of glass fiber ingredients effecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com