Ultralow temperature cured powder paint and application method thereof

A powder coating and application method technology, applied in powder coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor storage stability of UV-curable powder coatings, poor adhesion between coatings and substrates, and difficulty in obtaining raw materials. To achieve good surface effect and adhesion, full curing, fast ultra-low temperature curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

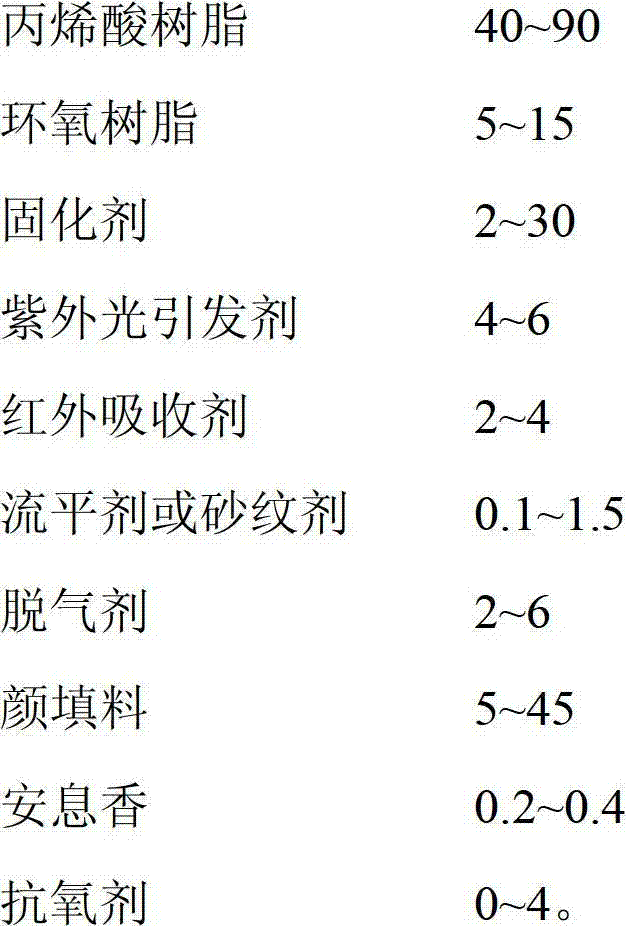

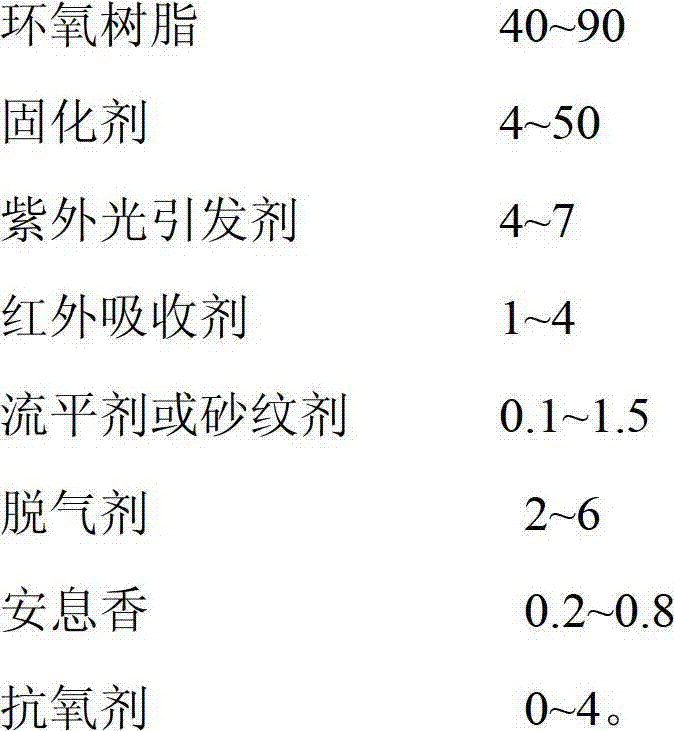

Embodiment 1

[0041]

[0042] The medium-wave infrared curing conditions are: 110°C curing for 6 minutes; the ultraviolet curing conditions are: 3KW ultraviolet mercury lamp irradiation for 20 seconds, the pigments and fillers are phthalocyanine blue and barium sulfate, and their mass ratio is 18:82. Phthalocyanine blue BGS is provided by Clariant, Germany, model B2G.

Embodiment 2

[0044]

[0045] The medium-wave infrared curing conditions are: 105° C. for 7 minutes; the ultraviolet curing conditions are: 2.8 KW ultraviolet mercury lamp irradiation for 25 seconds, and the pigments and fillers are the same as in Example 1.

Embodiment 3

[0047]

[0048] The medium-wave infrared curing conditions are: curing at 100°C for 8 minutes; the ultraviolet curing conditions are: 3.5KW ultraviolet mercury lamp irradiation for 16 seconds, and the pigments and fillers are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com