Efficient air cooler

An air cooler, high-efficiency technology, applied in steam/steam condensers, isolation devices, production fluids, etc., can solve the problems of high operation and maintenance costs, complex structure of sand removal tanks, and low heat exchange efficiency, and achieve low operation and maintenance costs. , The effect of reducing equipment procurement costs and space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

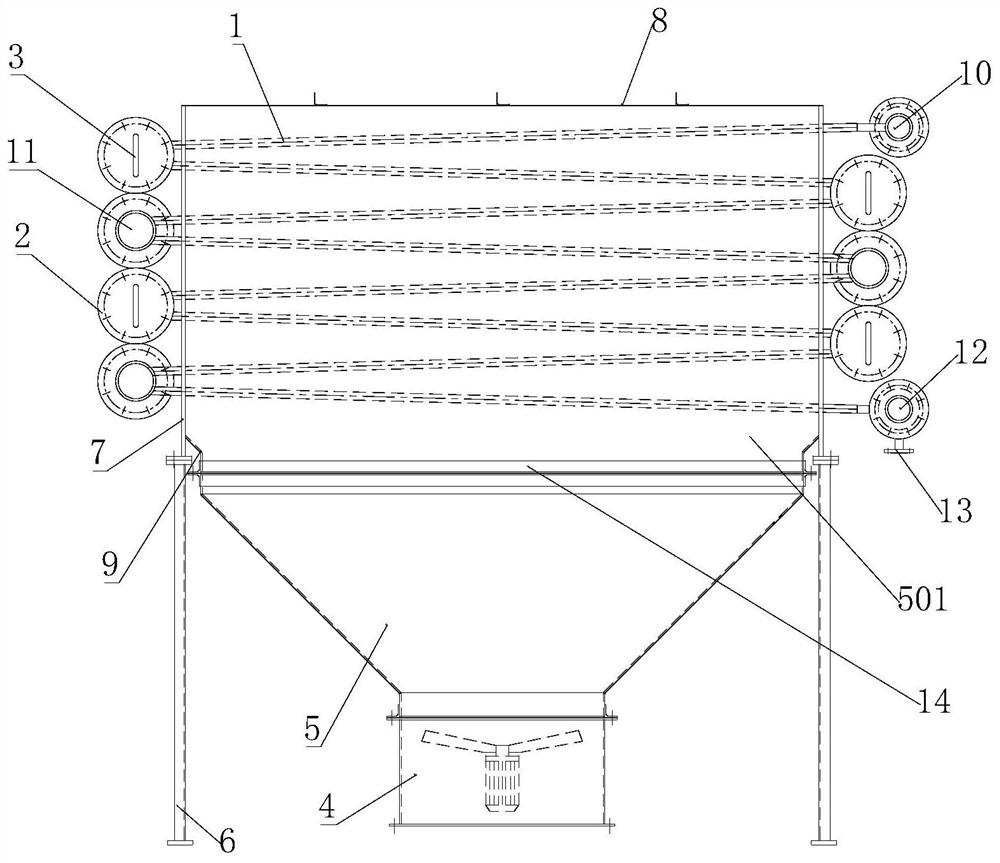

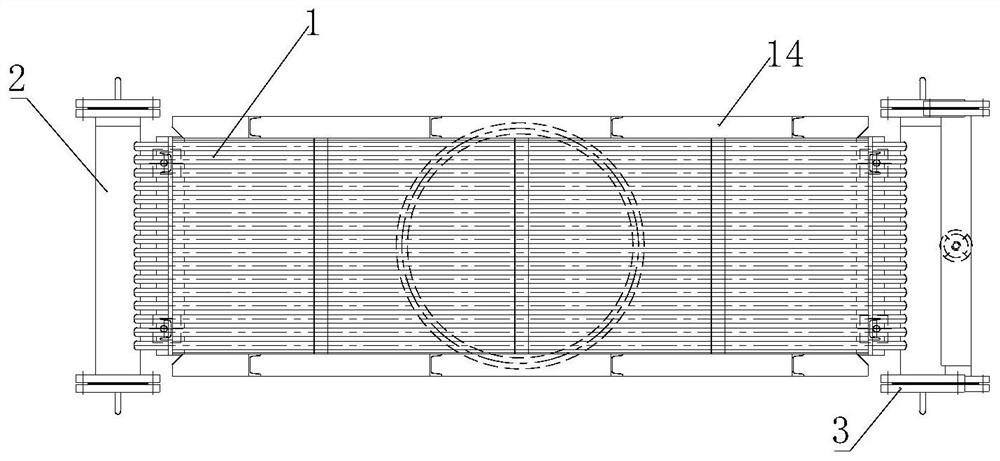

[0021] Example: such as figure 1 , figure 2 As shown, a high-efficiency air cooler includes heat exchange tubes, manifolds, end caps, explosion-proof fans, windshields, pillars, and tube sheets. There are two tube sheets, and the two tube sheets are arranged parallel to each other. Each tube sheet There are two pillars fixedly connected at the bottom, heat exchange tubes are arranged between the adjacent two sides of the tube sheet, the heat exchange tubes are rolled fins, and are installed obliquely, and the two opposite sides are respectively arranged in parallel along the surface of the tube sheet There are multiple headers, and the headers on the two tube plates are misplaced. The headers on both sides are connected in a "Z" shape through the heat exchange tubes. The end faces of the headers are equipped with end covers. The uppermost header One end is provided with a liquid inlet, and one end of the bottom manifold is provided with a liquid outlet and an exhaust and sew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com