Device and method for selective etching of solar cells

A technology for solar cells and etching devices, which is applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of large solution consumption, high equipment maintenance costs, and high requirements for spraying uniformity, and achieves good uniformity. , The effect of low maintenance cost and equipment procurement cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

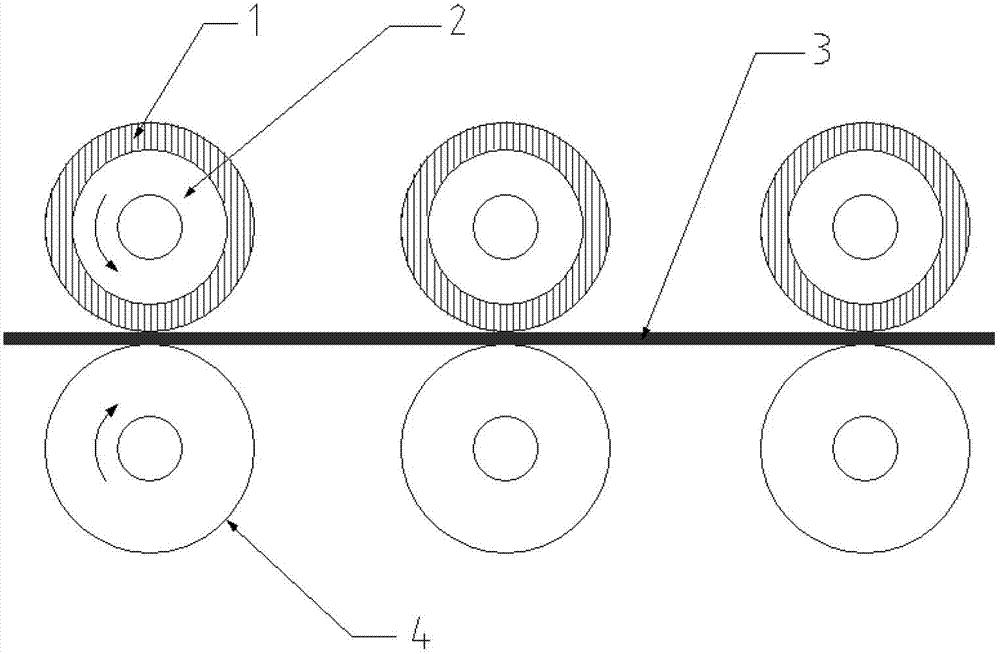

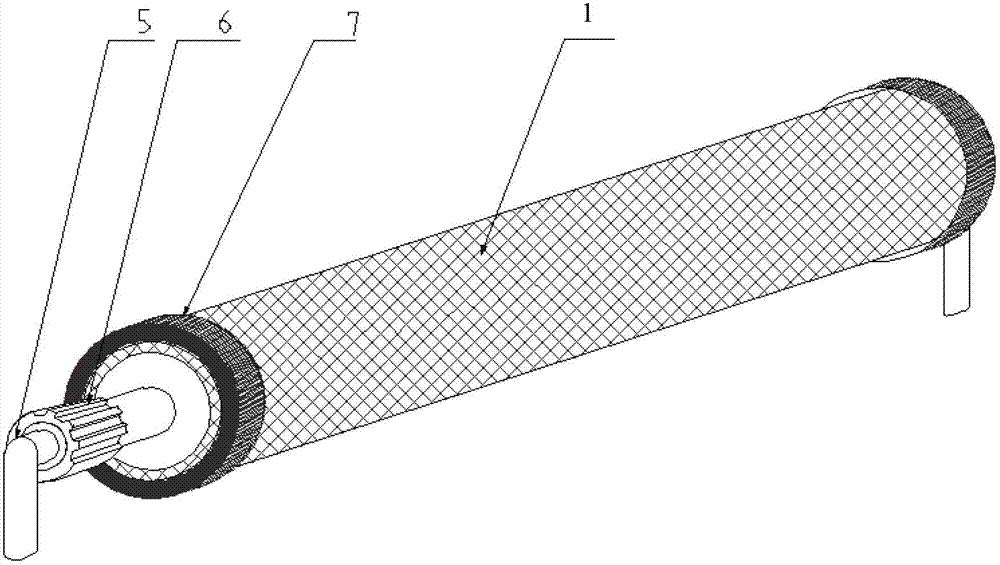

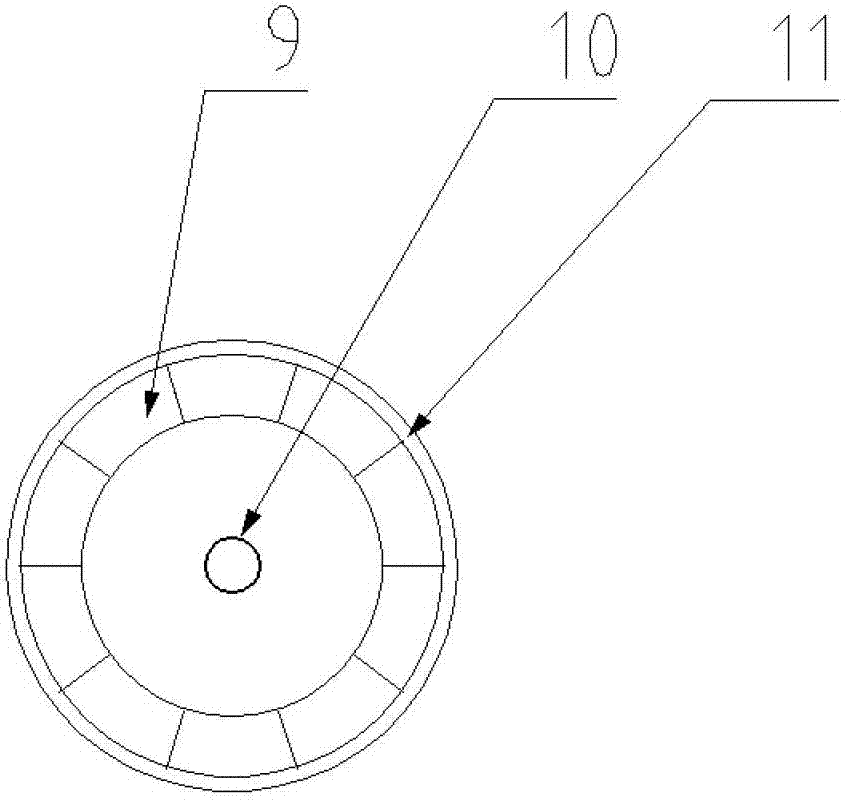

[0038] refer to figure 1 , the solar cell sheet selective etching device of the present embodiment includes: a transfer roller 4; a coating roller 2 arranged above the transfer roller 4, the surface of the coating roller 2 is coated with a liquid absorbing layer 1, and the coating roller 2 The distance from the transport roller 4 is smaller than the thickness of the solar battery sheet 3 . The transport roller 4 rotates to transport the solar cell sheet 3 , and the liquid-absorbing layer 1 is squeezed to apply the absorbed etching solution to the upper surface of the solar cell sheet 3 . Wherein, a mask pattern is pre-formed on the upper surface of the solar battery sheet 3 . For selective etching of the emitter, the etchant can be 10% HF and 30% HNO 3 of the mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com