Temperature, pressure and acoustics integrated MEMS underwater sensor and system

An underwater sensor and pressure technology, applied in the direction of instruments, measuring instrument components, measuring devices, etc., can solve the problems that polymer materials cannot be sensed and measured with high precision pressure, and the integration of temperature, pressure, and acoustic sensitive units cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Temperature, pressure, acoustics integrated MEMS underwater sensor

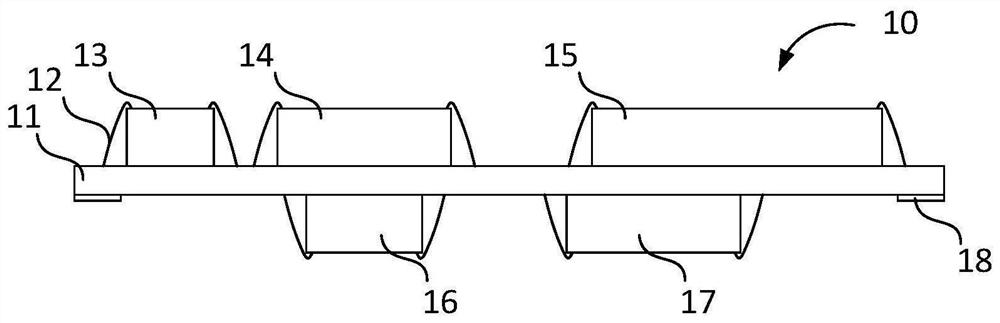

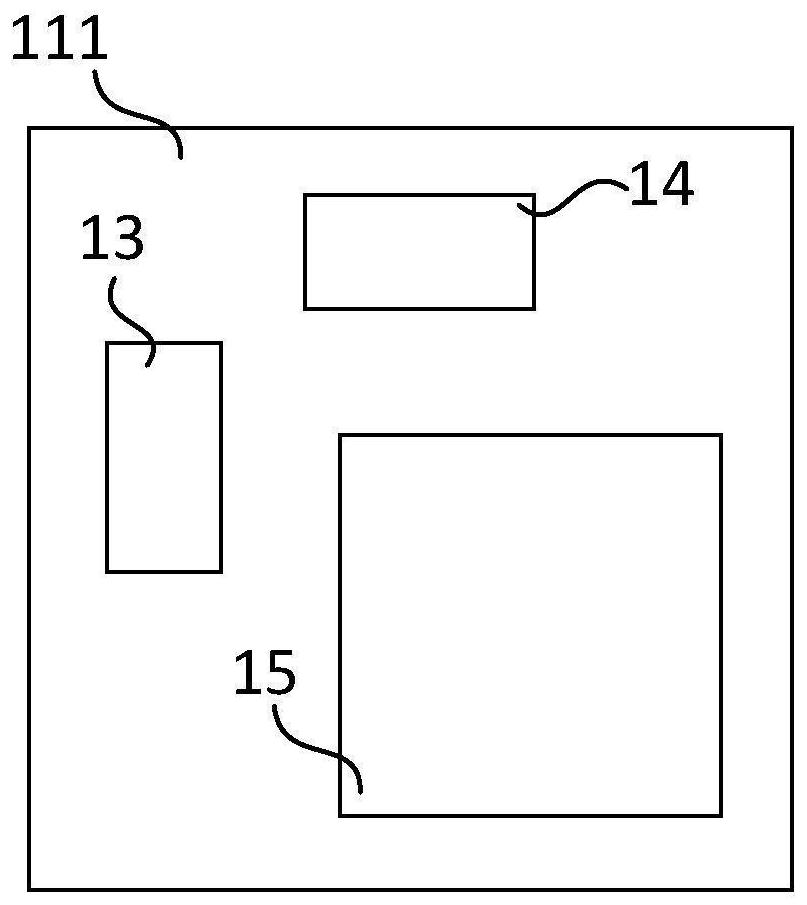

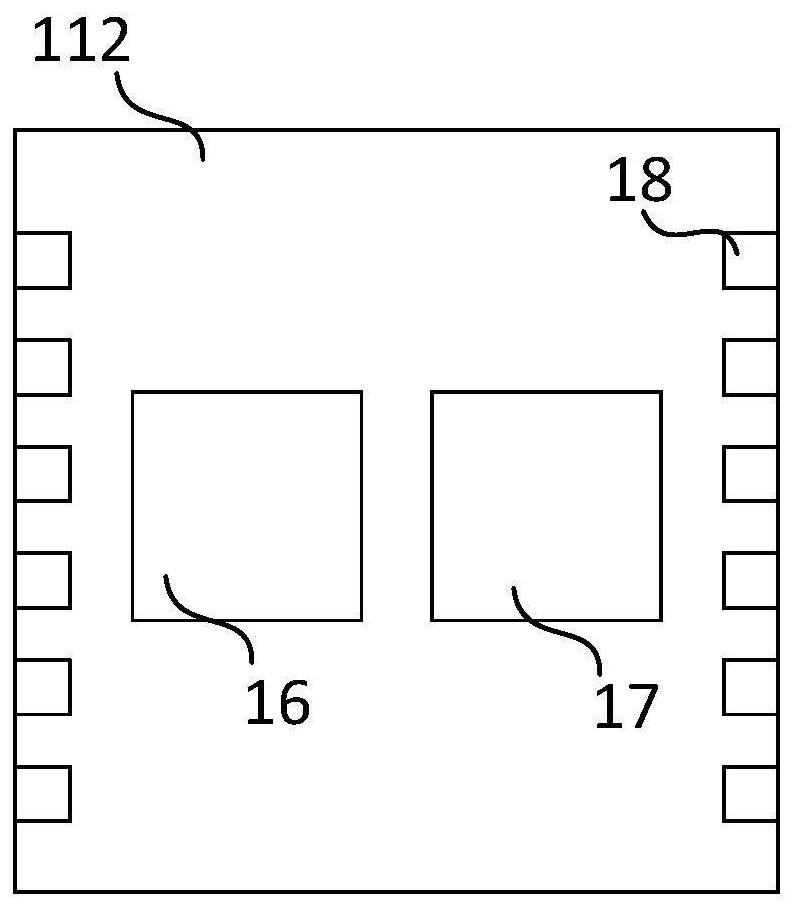

[0042] Such as Figures 1 to 3 As shown, the MEMS underwater sensor 10 includes acoustic vector sensing units 13 , 14 , an acoustic pressure sensing unit 15 and a temperature-pressure sensing unit 16 . Acoustic vector sensitive units 13, 14, the top surface 111 of the first carrier plate 11 of the sound pressure sensitive unit 15, and the temperature-pressure sensitive unit 16 is arranged on the bottom surface 112 of the first carrier plate 11; board bonding. Among them, the acoustic vector sensitive units 13, 14 and the sound pressure sensitive unit 15 located on the top surface of the first carrier are encapsulated by a sound-permeable cap, and the temperature-pressure sensitive unit 16 located on the bottom surface of the first carrier is encapsulated by a metal shell.

[0043]Acoustic vector sensitive units 13 and 14 are horizontally and orthogonally placed on the same plane, and can perceive the...

Embodiment 2

[0046] Temperature, pressure, acoustics integrated MEMS underwater sensor

[0047] The main difference between the second embodiment and the first embodiment is that the pressure sensitive unit and the temperature sensitive unit of the MEMS underwater sensor are arranged separately; the signal conditioning unit is laminated and arranged below the temperature sensitive unit.

[0048] Such as Figure 4 As shown in -6, the MEMS underwater sensor 20 includes acoustic vector sensitive units 23 and 24, an acoustic pressure sensitive unit 25, a pressure sensitive unit 26, and a temperature sensitive unit 27. Acoustic vector sensing units 23 and 24 are horizontally and orthogonally placed on the same plane, and can perceive the particle velocity information in two dimensions in the underwater sound field, and the sound pressure sensing unit 25 can sense the sound pressure information in the underwater sound field. Considering the sound transmission requirements of the acoustic sensit...

Embodiment 3

[0051] Temperature, pressure, acoustics integrated MEMS underwater sensor

[0052] The main difference between the third embodiment and the second embodiment is that the signal conditioning unit is arranged in parallel with the pressure sensitive unit and the temperature sensitive unit.

[0053] Such as Figure 7 Shown in -9, MEMS underwater sensor 30 is made up of acoustic vector sensitive unit 33 and 34, sound pressure sensitive unit 35, pressure sensitive unit 36, temperature sensitive unit 37 and signal conditioning unit 38, and acoustic vector sensitive unit 33 and 34 are the same The plane is placed horizontally and orthogonally, and can sense particle velocity information in two dimensional directions in the underwater sound field, and the sound pressure sensitive unit 35 can sense sound pressure information in the underwater sound field. Considering the sound transmission requirements of the acoustic sensitive units 33, 34 and 35 and the high-precision measurement req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com