Wind power tower oil seal platform welding residual stress prediction and welding process optimization method

A wind power tower, residual stress technology, applied in design optimization/simulation, special data processing applications, image data processing, etc., can solve problems such as economic loss, cracking, damage, cracking or deformation, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment introduces a method for predicting welding residual stress of a wind power tower oil seal platform, including:

[0044] Obtain the structural parameters of the wind power tower, as well as welding material parameters, welding methods and heat source parameters;

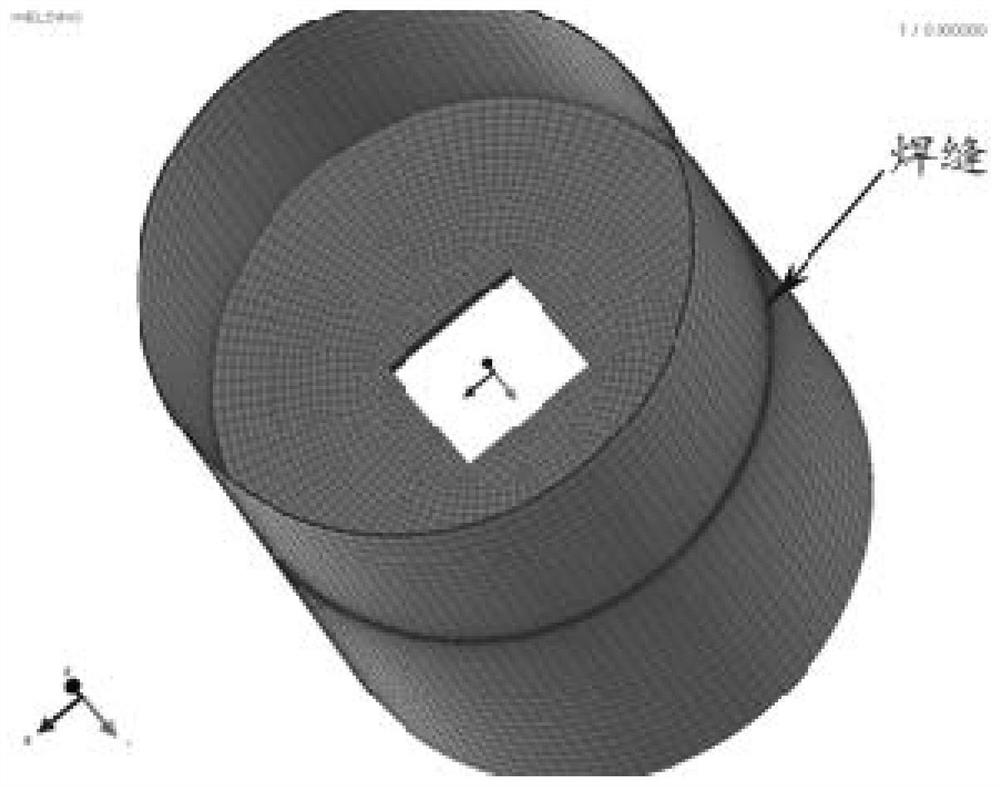

[0045] Establish a three-dimensional model of the wind power tower including welds according to the structural parameters of the wind power tower;

[0046] Determine the heat source model according to the welding method;

[0047] Carry out finite element mesh division for the three-dimensional model of the wind power tower;

[0048] Based on the three-dimensional model of the wind power tower after finite element mesh division, heat source model, heat source parameters and welding material parameters, the welding simulation is carried out, and the temperature field and stress field in the welding process are analyzed by finite element, and the wind power tower is welded. The final residual str...

Embodiment 2

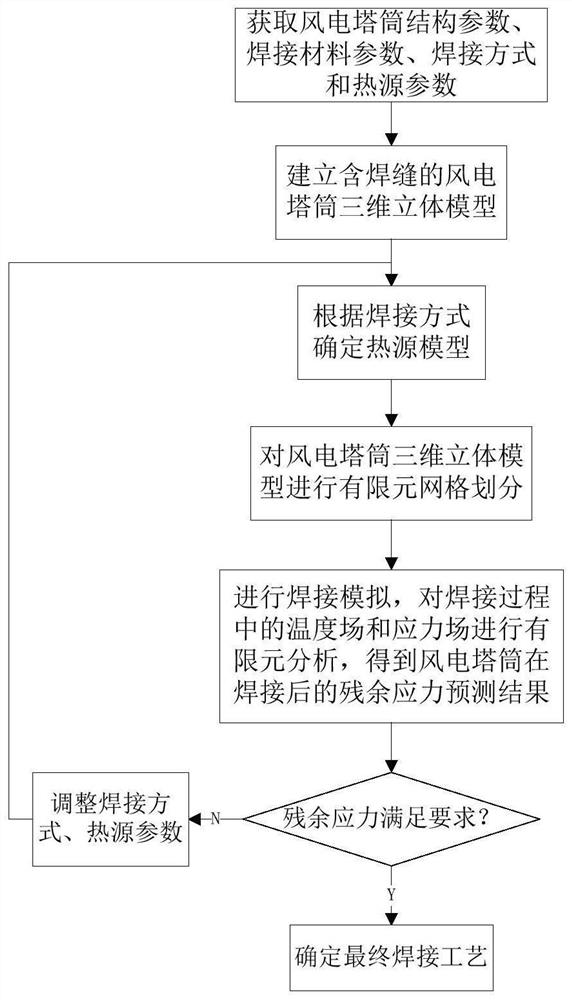

[0057] This embodiment introduces a method for optimizing the welding process of the wind power tower oil seal platform. figure 1 ,include:

[0058] Obtain the structural parameters of the wind power tower, and pre-determine the welding material parameters, welding methods and heat source parameters;

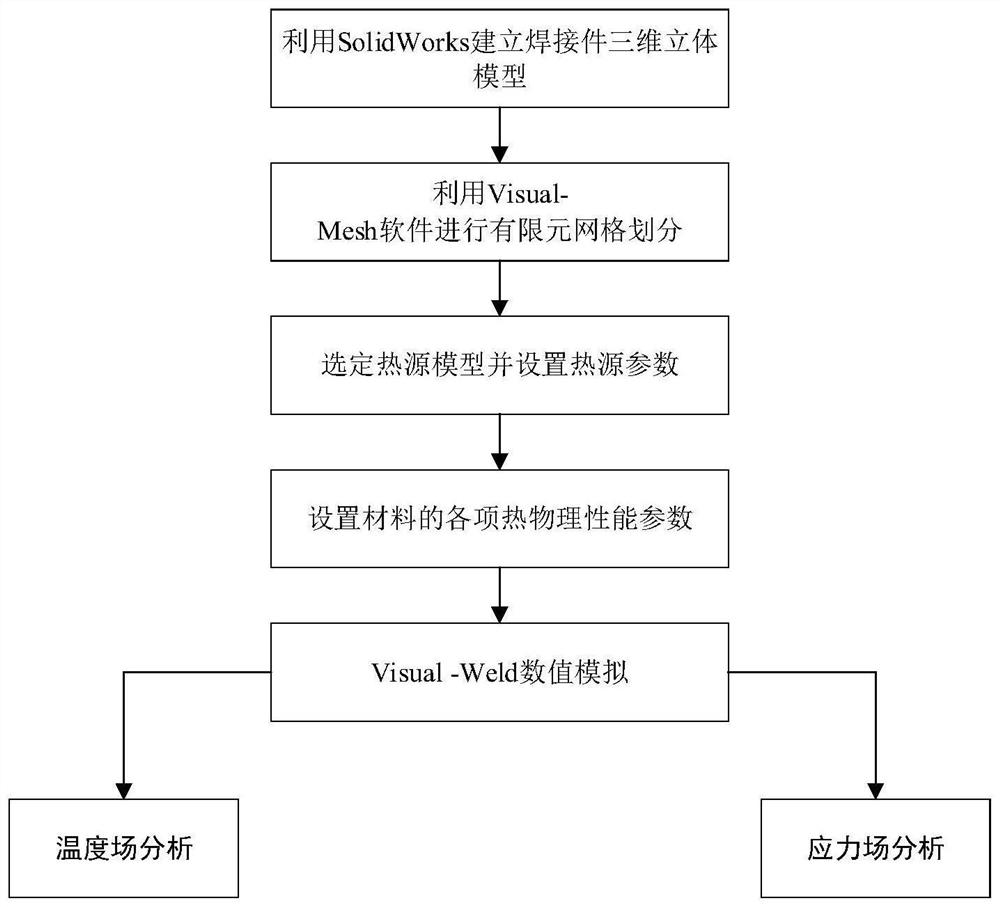

[0059] According to the structural parameters of the wind power tower, use SolidWorks software to establish a three-dimensional model of the wind power tower;

[0060] Determine the heat source model according to the predetermined welding method;

[0061] Using Visual-Mesh software to divide the 3D model of wind power tower into finite element mesh;

[0062] Based on the three-dimensional model of the wind power tower after finite element mesh division, heat source model, heat source parameters and welding material parameters, use Visual-Weld numerical simulation software to carry out welding simulation, and conduct finite element analysis on the temperature field and stress f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com