Lithium battery isolating membrane processing equipment convenient to adjust and processing technology

A processing equipment and isolation film technology, applied in the field of lithium battery isolation film processing equipment and processing technology, can solve problems such as inability to achieve synchronous fixation, affect efficiency, troubles, etc., and achieve the effect of convenient and quick adjustment and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

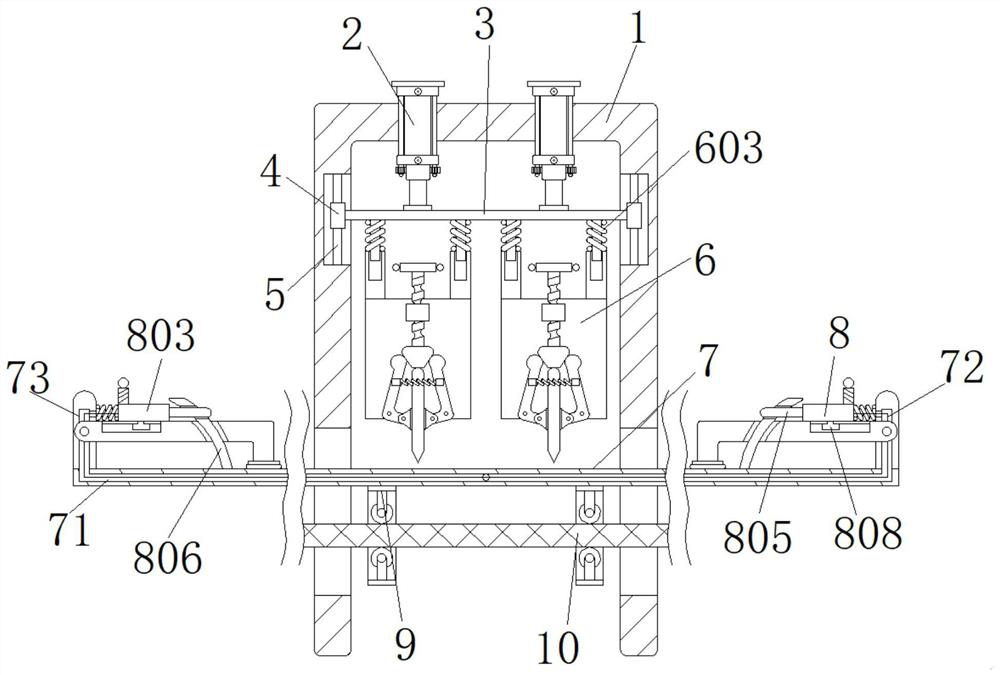

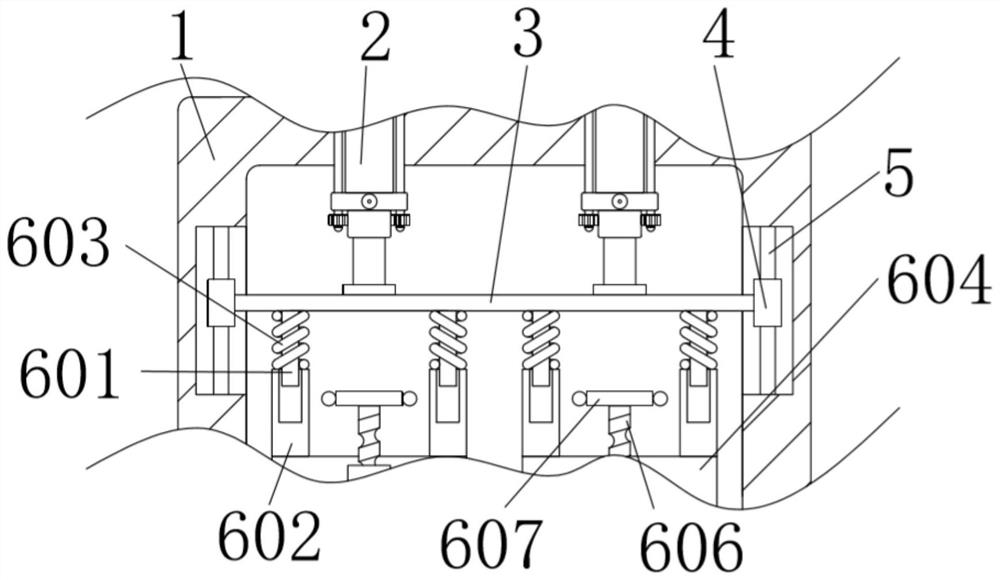

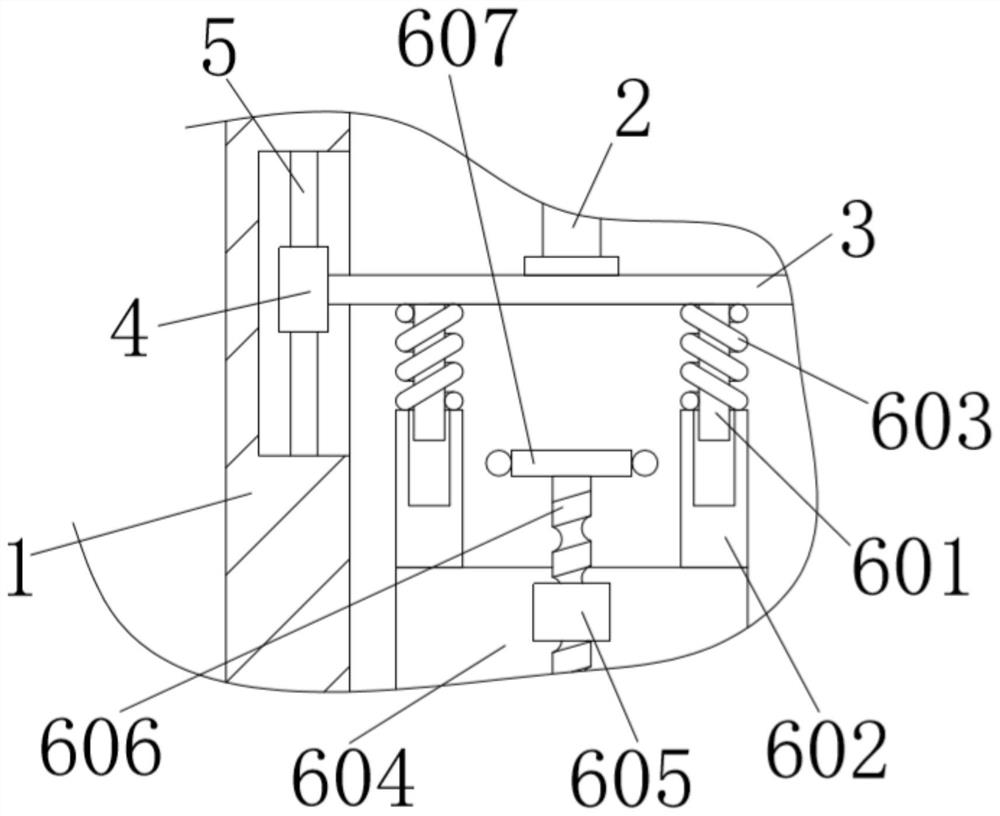

[0037]An easy-to-adjust lithium battery separator processing equipment, including a first casing 1, a hydraulic cylinder 2, a horizontal plate 3, a slider 4 and a sliding rod 5, the top inner wall of the first casing 1 is fixedly connected with a hydraulic cylinder 2, and the hydraulic cylinder The model of 12 is MOB, the bottom of the hydraulic cylinder 2 is fixedly connected with the horizontal plate 3, the left and right ends of the horizontal plate 3 are respectively fixedly connected with the slider 4, the inner wall of the slider 4 is slidably connected with the slider 5, and the slider 4 can be Slide up and down on the outer wall of the slide bar 5, the upper and lower ends of the slide bar 5 are respectively fixedly connected to the upper and lower sides of the upper and lower grooves on the left and right sides of the inner wall of the first shell 1, and a cutting device 6 is arranged above the inner wall of the first shell 1, The cutting device 6 comprises a short rod...

Embodiment 2

[0039] As an option, see figure 1 and 6 , 7, the processing equipment and processing technology of the lithium battery separator, the top left and right sides of the long board 7 are provided with a fixing device 8, the fixing device 8 includes a vertical board 801, a third spring 802, a short board 803, and a second handle 804 , a round bar 805, an arc plate 806, a curved plate 807 and a square plate 808, the bottom of the vertical plate 801 is fixedly connected with the top left side of the long plate 7, and the upper left side of the vertical plate 801 is fixedly connected with a third spring 802, short When the plate 803 moves to the left, the third spring 802 is compressed, and the third spring 802 generates a rebound force to return the short plate 803. The right end of the third spring 802 is fixedly connected with the short plate 803, and the bottom of the short plate 803 is fixedly connected There is a square plate 808, the bottom of the outer wall of the square plat...

Embodiment 3

[0044] The processing equipment and processing technology of the lithium battery separator, when using the processing equipment and processing technology of the lithium battery separator, first place the device on a flat ground, and place the separator to be cut on the long board 7 , first pull the second handle 804 to move the short plate 803 and the round rod 805 away from the device, at this time, press the curved plate 807 against the isolation film, so that the curved plate 807 is tightly against the isolation film, and then loosen the second handle 804, At this time, the round bar 805 is under the action of the rebound of the third spring 802, so that the round bar 805 is clamped into the arc plate again to realize fixing. After fixing, the hydraulic cylinder 2 is connected to the outer wall numerical control equipment, the hydraulic cylinder 2 works normally, and the pulley 9 The inner hub motor is connected to the external power supply, and the hub motor works normally....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com