Lead-acid storage battery posture placing and discharging device

A lead-acid battery and discharge device technology, used in lead-acid batteries, battery recycling, waste collector recycling, etc., can solve the problem of not being able to automatically place the battery posture, solve the problem of automatic identification and placement, and eliminate potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

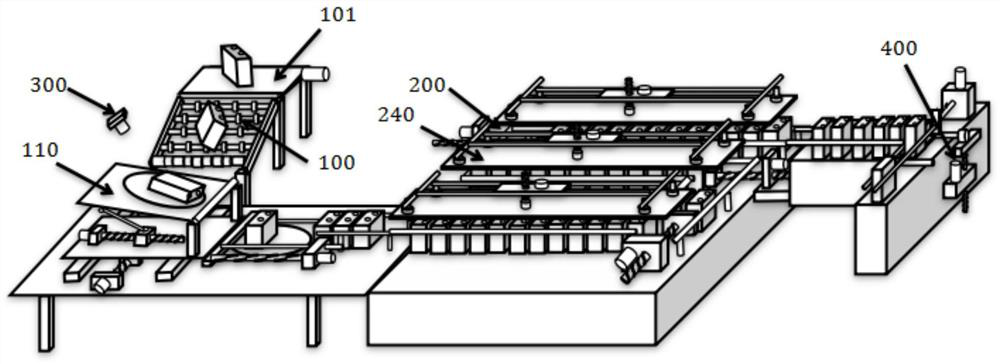

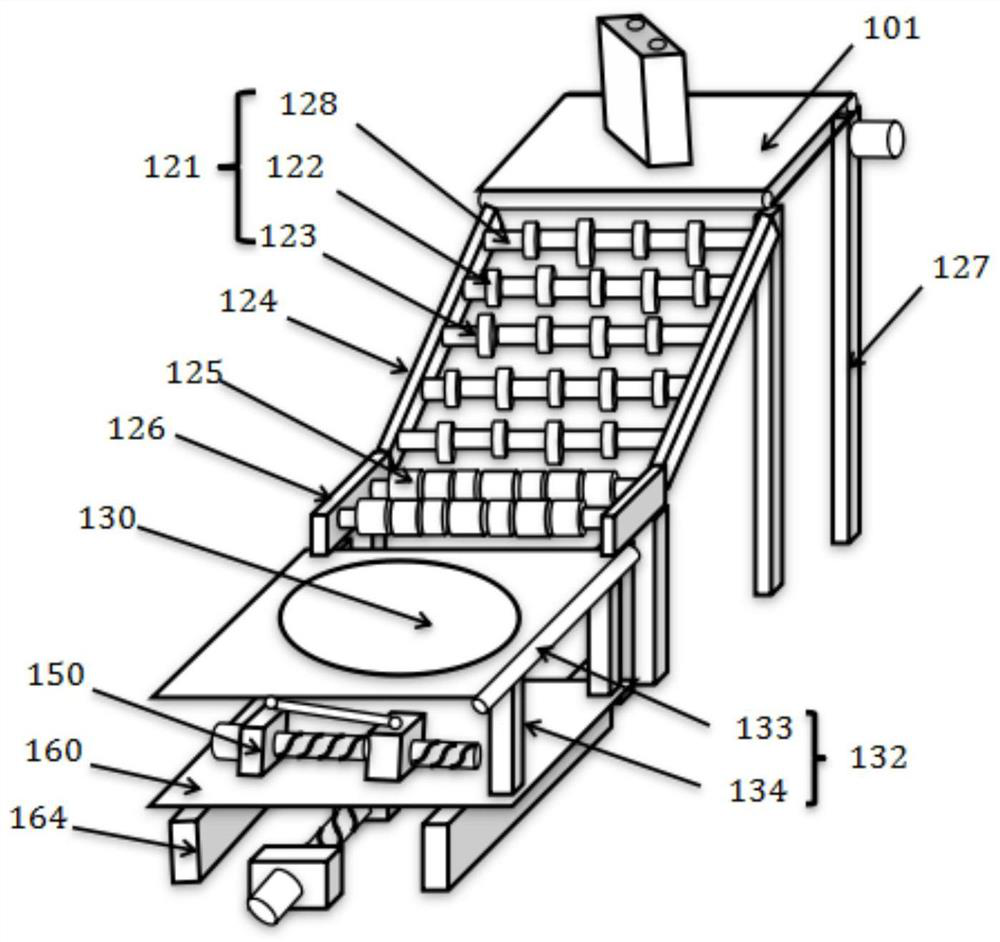

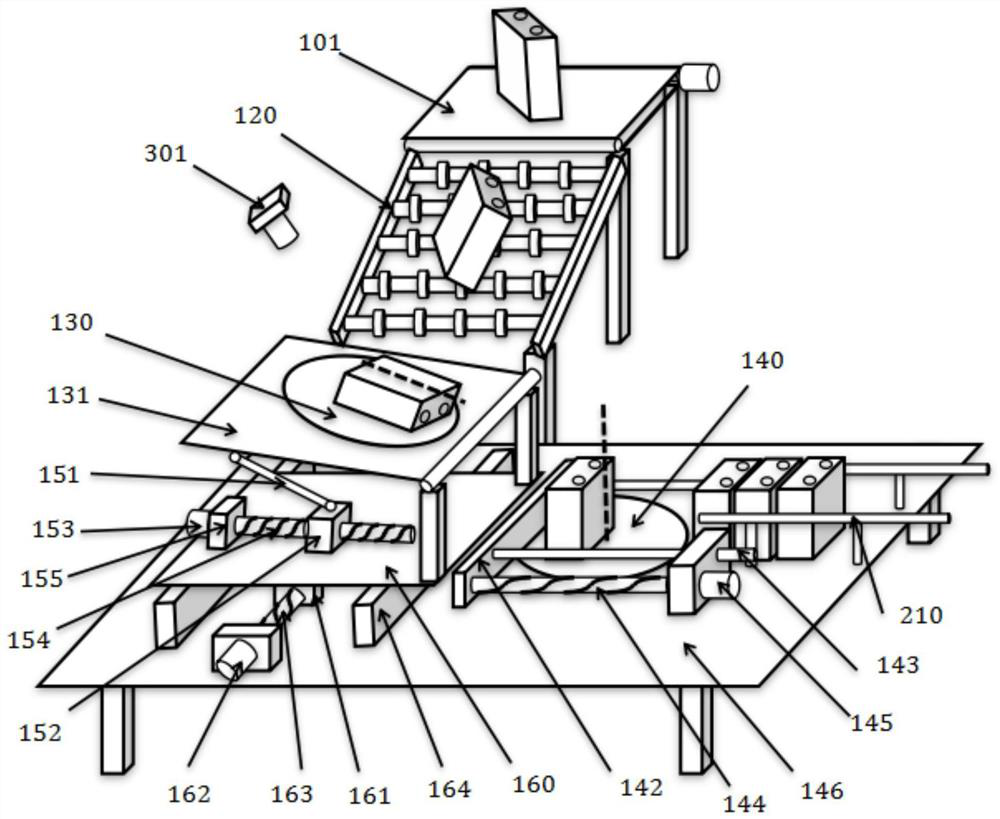

[0026] Such as figure 1 As shown, a lead-acid battery posture placement and discharge device includes: a roller table unit 100 , an attitude adjustment unit 110 , a discharge unit 200 , an image recognition unit 300 and a battery tilt unit 400 . Such as figure 2 As shown, the battery conveyor belt 101 is arranged on one side of the roller table unit 100 for the incoming of the battery. The roller table unit 100 includes more than one set of idler roller devices 120, and the roller table device 120 is composed of more than one set of convex and concave idler rollers 121 and equal diameter idler rollers 125, and the two sets of idler rollers are respectively supported on the first idler rollers. on the bracket 124 and the second bracket 126 . Wherein, the first roller bracket 124 has a certain inclination angle with the horizontal plane, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com