Motor

A casing and oil circuit technology, applied in the direction of motors, electromechanical devices, electric vehicles, etc., can solve the problems of high heat generation of the motor rotor core, high temperature rise of the magnetic steel, and large space occupation, and improve the cooling effect , compact layout and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0043] The present invention will be described in detail below with reference to the accompanying drawings and examples.

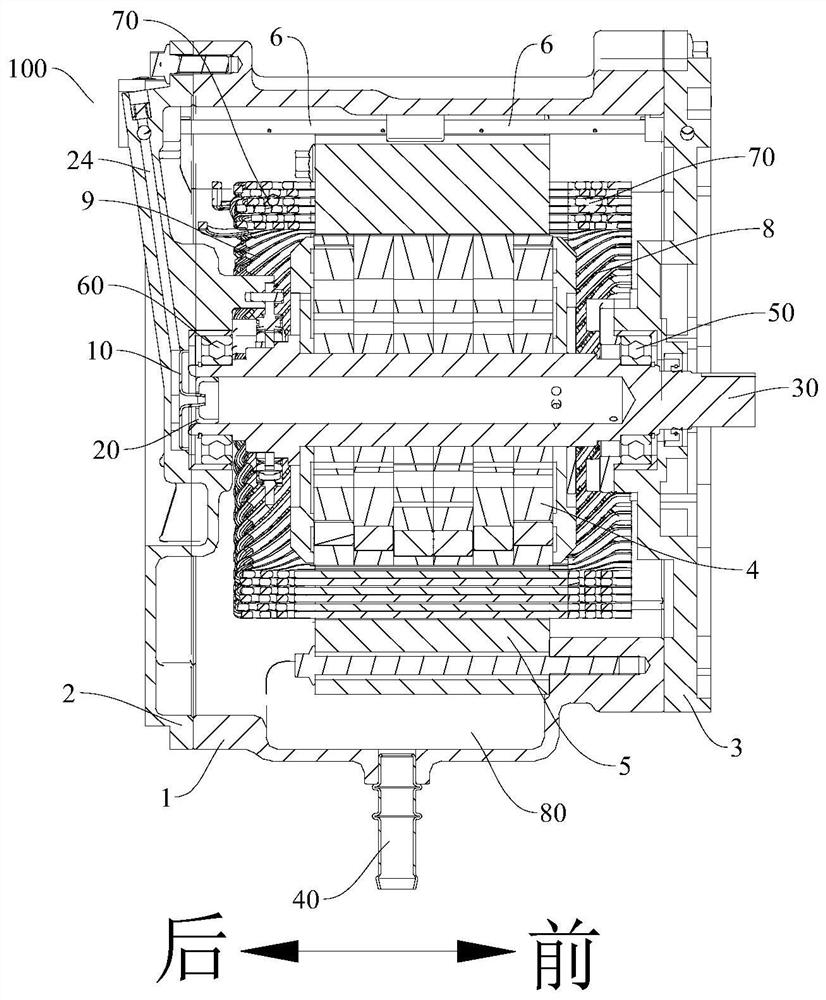

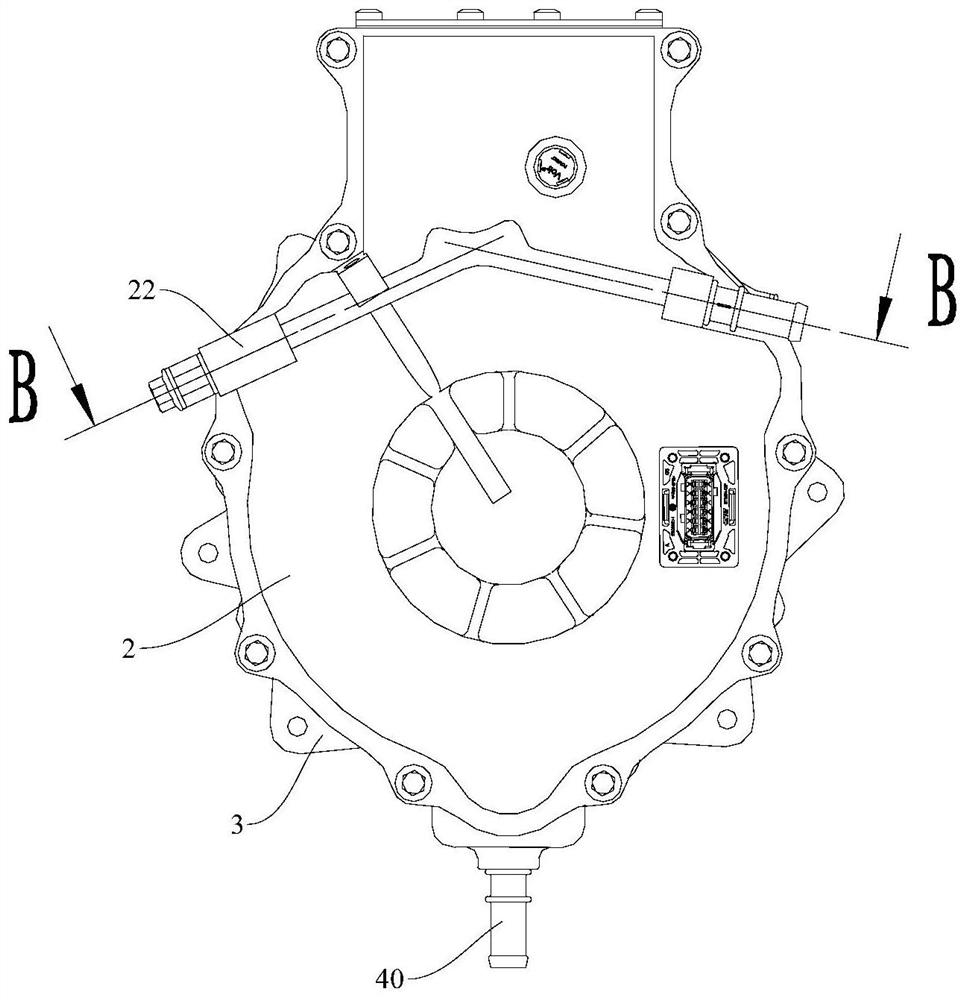

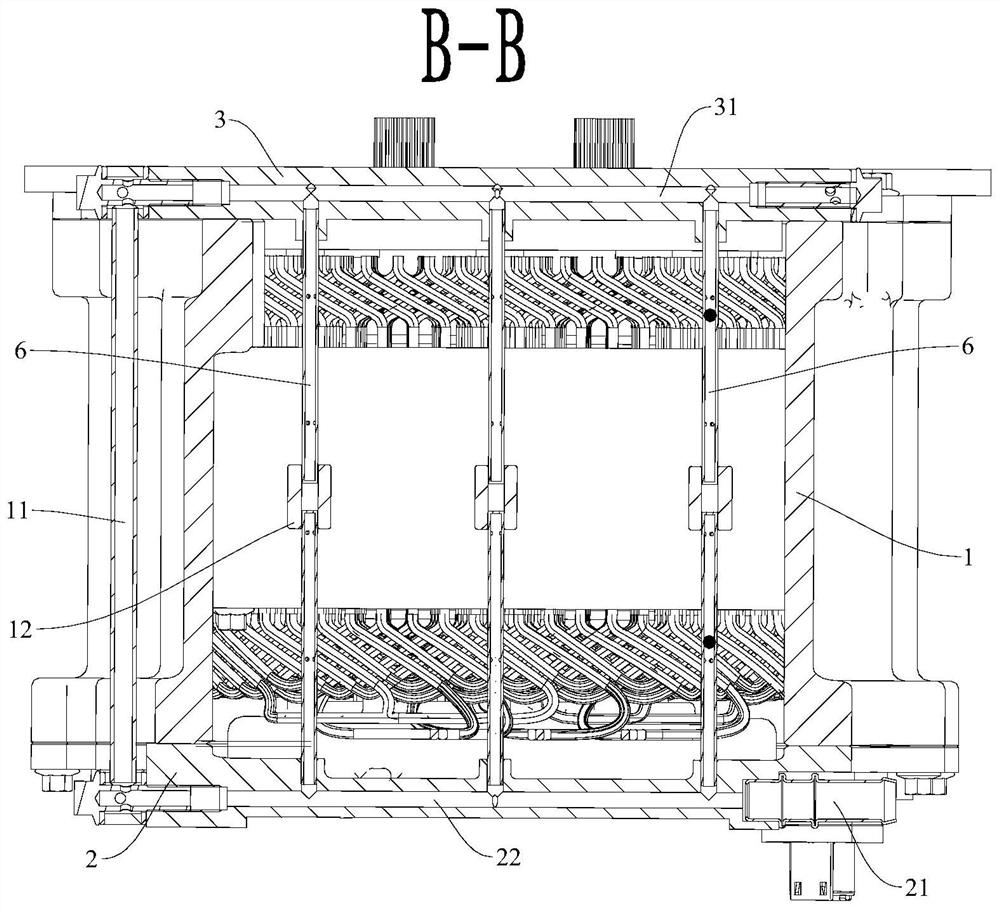

[0044]The motor 100 according to one embodiment of the invention includes: a casing 1 , a rear end cover 2 , a front end cover 3 , a stator and at least one set of fuel injection pipes 6 . Wherein, the rear end cover 2 and the front end cover 3 are installed on the rear end surface and the front end surface of the casing 1 respectively, the rear end cover 2 is provided with an oil inlet pipe 21 and a rear end cover oil passage 22 communicated with the oil inlet pipe 21, the front end The cover 3 is provided with a front cover oil passage 31, and both the front end cover oil passage 31 and the rear end cover oil passage 22 are designed as cross oil passages, and the angle between the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com