Automatic operation control method and system for diaphragm filter press

A technology of automatic operation and filter press, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problem of inability to effectively apply diaphragm filter presses, inability to realize fully automatic control of diaphragm filter presses, and low degree of automation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

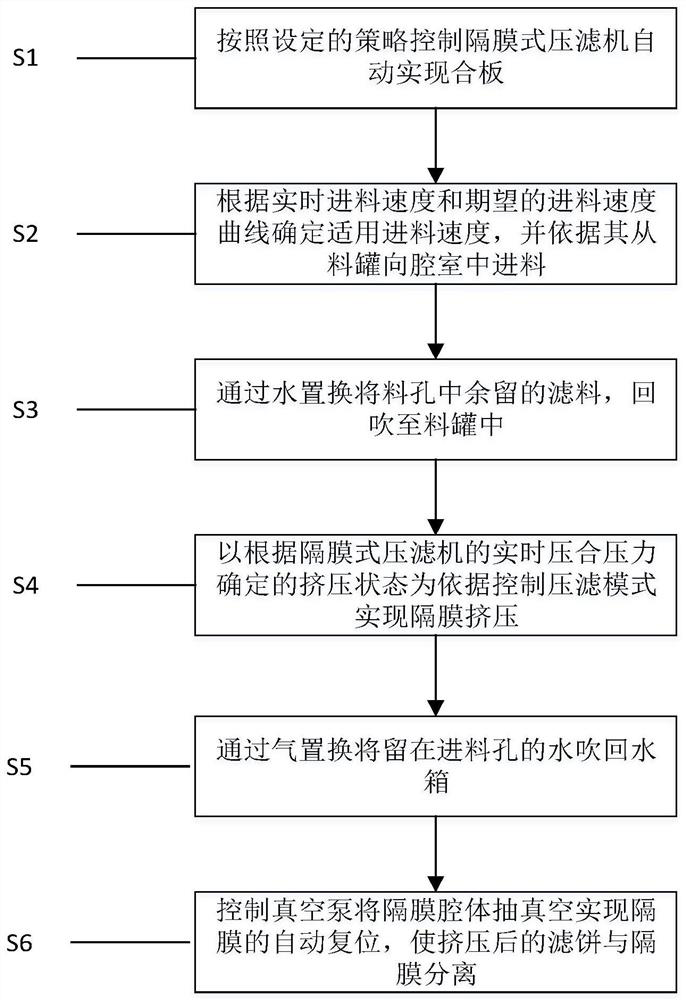

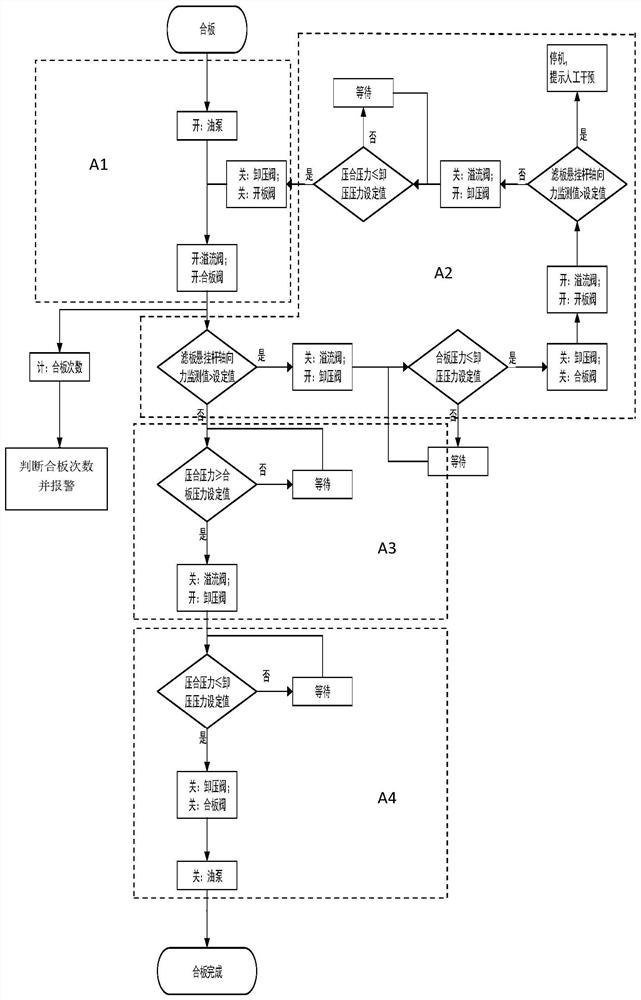

[0081] figure 1 It shows a schematic flow chart of the automatic operation control method for the diaphragm filter press provided by Embodiment 1 of the present invention, refer to figure 1 It can be seen that the method includes the following steps.

[0082] Step S1, controlling the diaphragm filter press to automatically realize the plywood according to the set strategy;

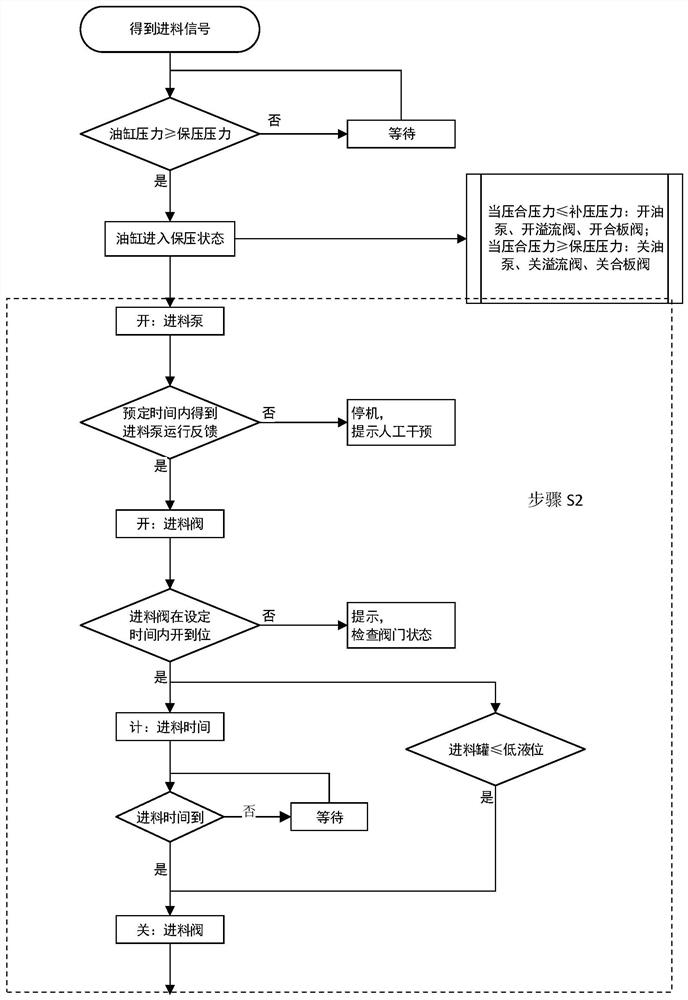

[0083] Step S2, after the plywood is completed, determine the applicable feed rate according to the real-time feed rate combined with the expected feed rate curve, and control the volumetric mud feeding equipment to feed the material from the material tank to the chamber of the diaphragm filter press according to it ; Wherein, because the filtration characteristic of filter press is: along with the increase of feed amount, the specific resistance of the solid-liquid mixture in the filter press chamber increases, and the filtrate passing speed decreases, and the filtration capacity is a gradual decline tre...

Embodiment 2

[0181] The present invention also provides an automatic operation control system for a membrane filter press, which executes the methods and steps in any one or more of the above embodiments.

[0182] specifically, Figure 4 A schematic structural view of an automatic operation control system for a membrane filter press provided by an embodiment of the present invention is shown, as Figure 4 As shown, the system specifically includes:

[0183] Automatic plywood module 41, which is configured to control the diaphragm filter press to automatically realize plywood according to a set strategy;

[0184] The feeding module 42 is configured to determine the applicable feeding speed according to the real-time feeding speed combined with the desired feeding speed curve after the plywood is completed, and to control the volumetric mud feeding equipment from the feed tank to the diaphragm filter press according to the feed speed. Feeding in the chamber;

[0185] The water replacement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com