Multi-station seat welding workstation

A welding workstation and multi-station technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of insufficient weld height and strength, unstable weld quality, and high labor intensity of workers, and achieve Save labor cost, reasonable structure design, high welding quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

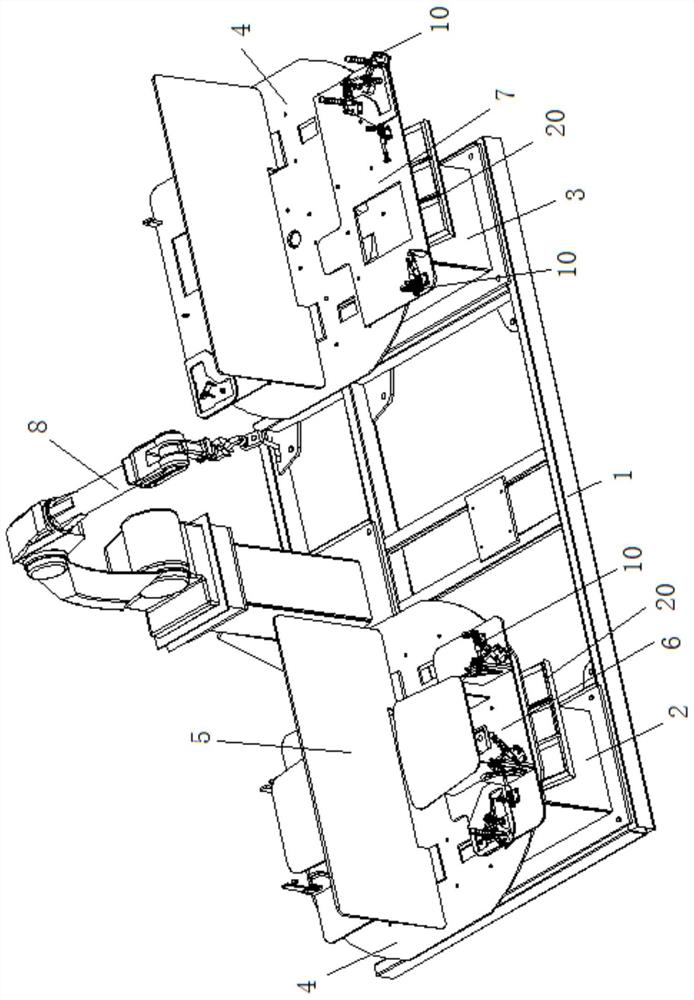

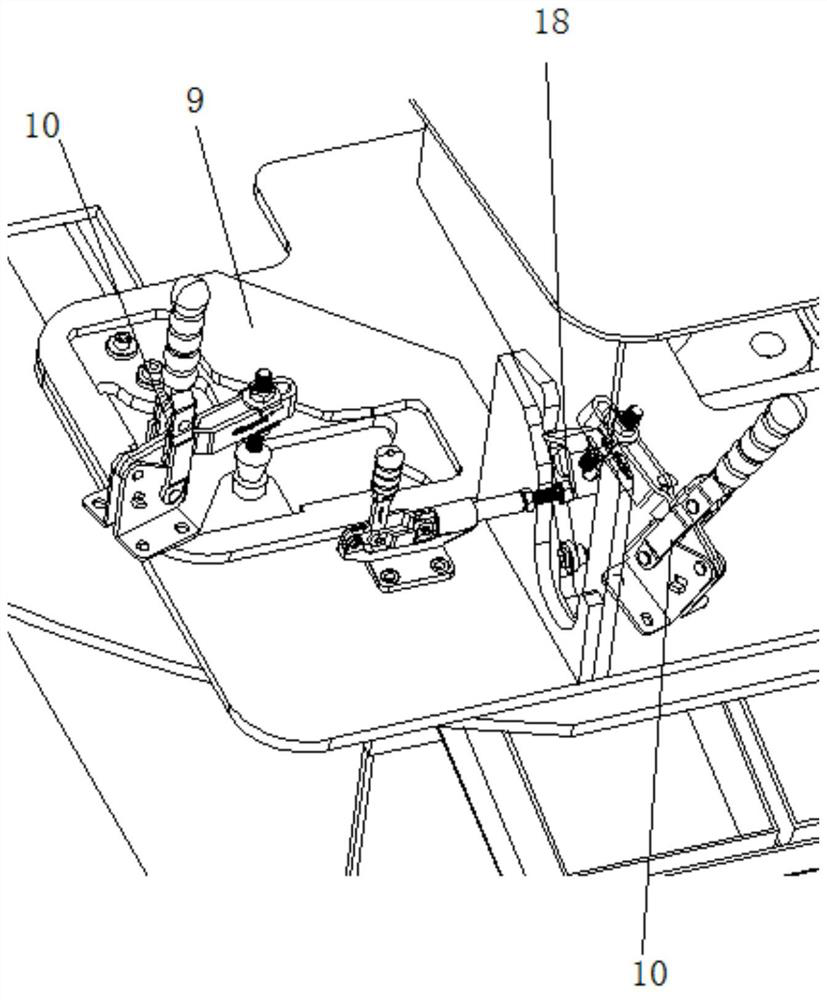

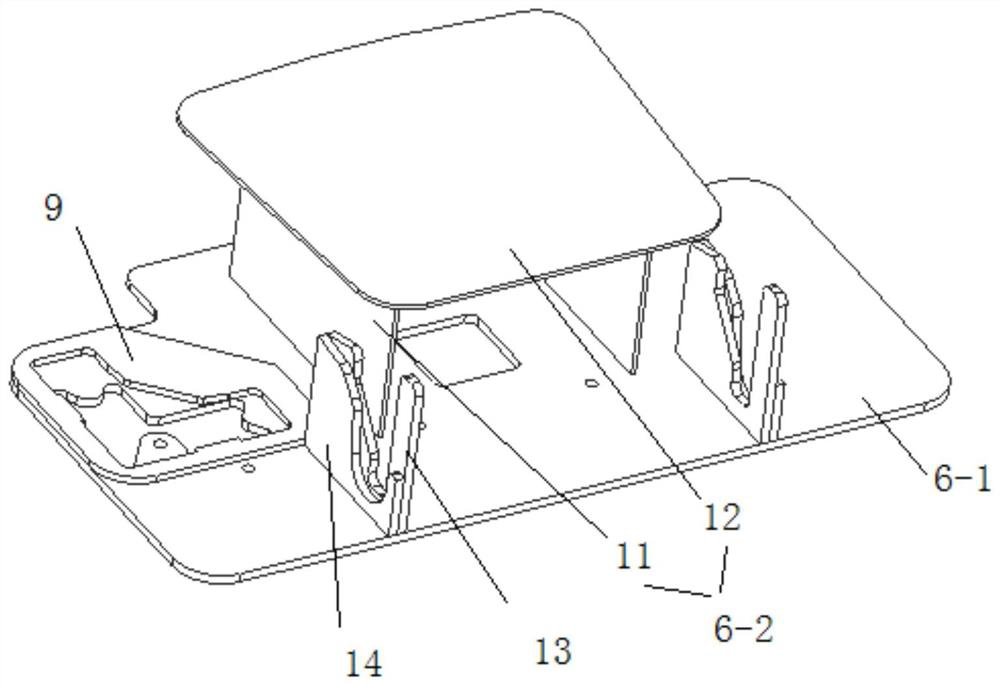

[0027] See attached picture.

[0028] A multi-station seat welding workstation, including a station base 1, and the two ends of the station base 1 are respectively equipped with a positioner 1 2 and a positioner 2 3, a positioner 2 and a positioner 2 3 Rotary table 4 is respectively installed on the rotary table 4. Two symmetrical stations are respectively arranged on the rotary table 4, and the stations are separated by a partition 5. The two stations of positioner one 2 are respectively installed with The seat plate mold 6 for the seat plate and the side support plate, the seat plate mold 6 includes a bottom plate 6-1, the middle part of the bottom plate 6-1 is equipped with a support plate 6-2 for supporting the seat plate body, and the support plate 6 The outer side of -2 is equipped with two symmetrically arranged clamping plate assemblies 6-3 for clamping the side support plates on both sides of the positioning seat plate, and the two stations of the positioner 23 are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com