Icebreaking type asphalt waterproof coating brushing device

A kind of asphalt waterproof coating and ice-breaking technology, applied in the direction of construction, building structure, etc., can solve the problems of extended construction period, poor ice-breaking effect, waste of waiting time, etc., and achieve the effect of extending the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

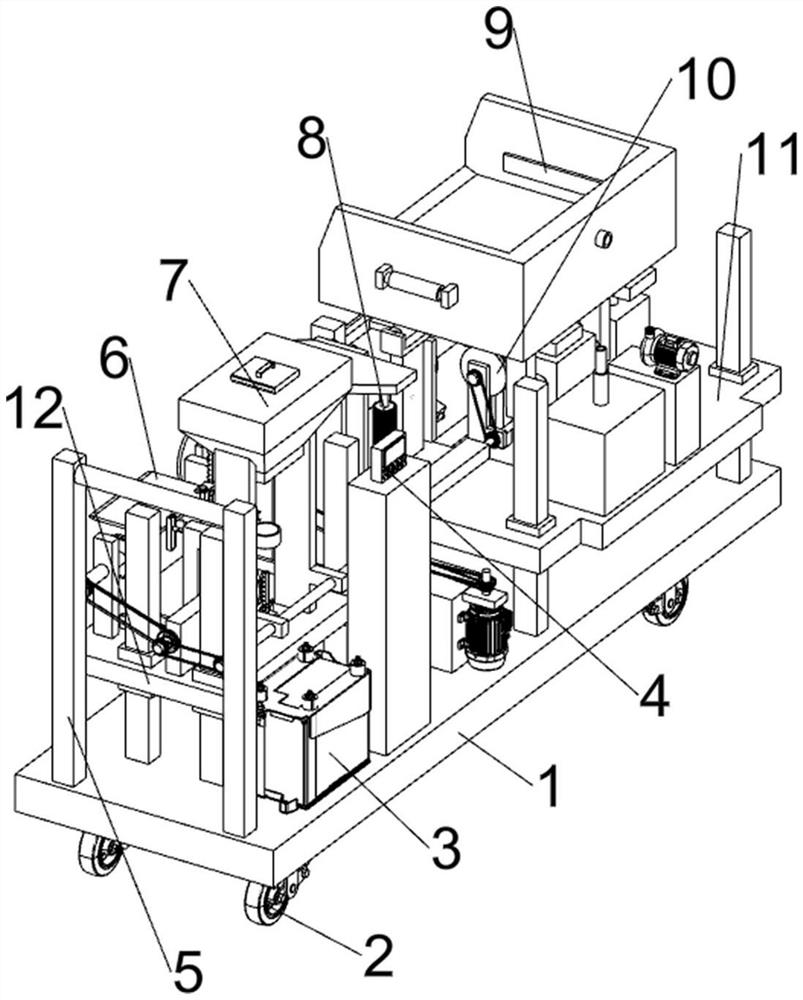

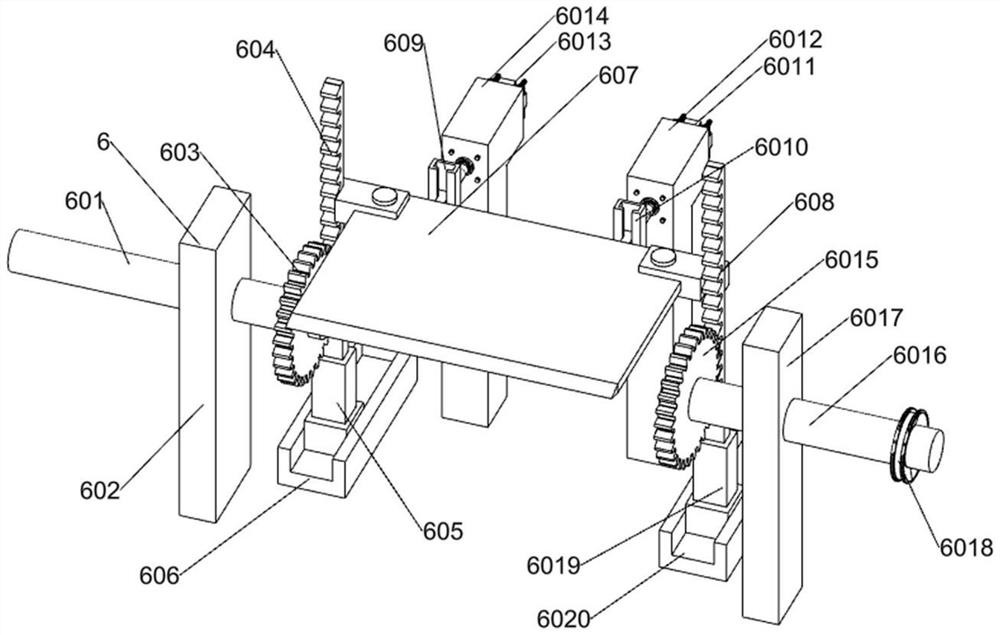

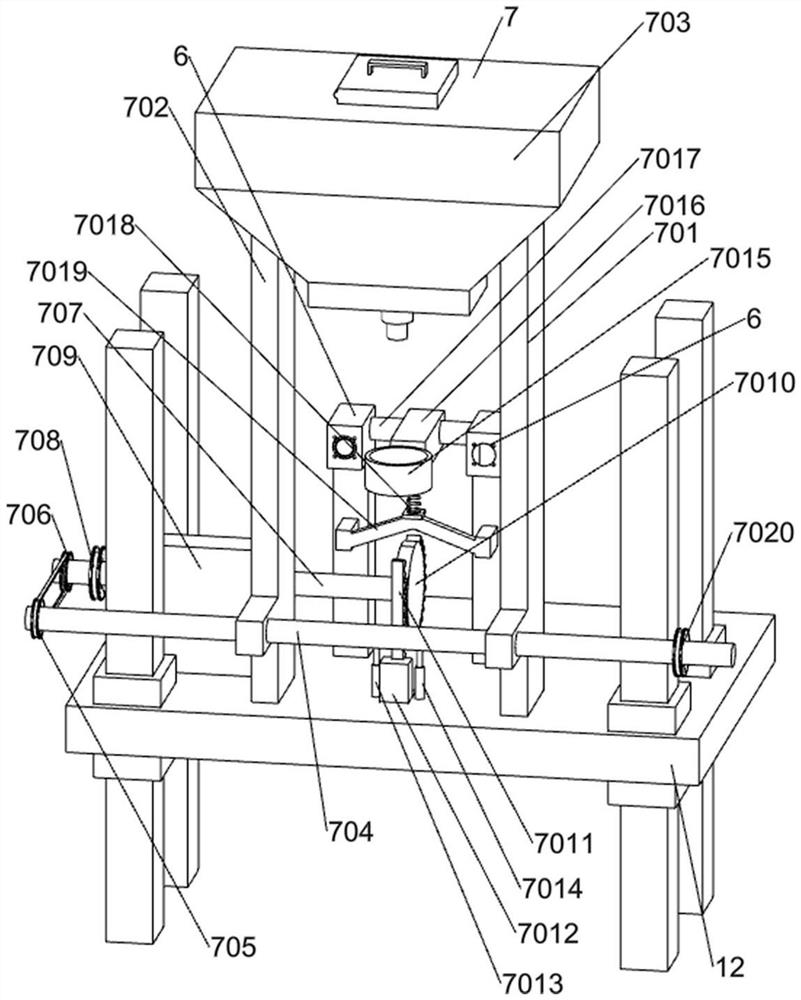

[0030] An ice-breaking asphalt waterproof coating device, such as Figure 1-9 As shown, it includes lathe board 1, wheel 2, battery 3, operation control panel 4, push handle 5, ice breaking system 6, salt feeding system 7, water absorption drying system 8, paint pouring system 9, scraping system 10, the first An elevating workbench 11 and a second elevating workbench 12; the lower part of the lathe board 1 is bolted to the wheel 2; the upper part of the lathe board 1 is connected to the battery 3; the upper part of the lathe board 1 is connected to the operation control panel 4; the upper part of the lathe board 1 Weld with the push handle 5; the top of the lathe plate 1 is connected with the first lifting table 11; the top of the lathe plate 1 is connected with the second lifting table 12; the top of the second lifting table 12 is sequentially connected with the ice breaking system 6 and the casting The salt system 7 is connected; the ice breaking system 6 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com