Construction method beneficial to horizontal force resistance of multi-layer special-shaped steel structure building

A construction method and technology of steel structure, applied in basic structure engineering, processing of building materials, construction, etc., can solve problems such as difficult and huge horizontal tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

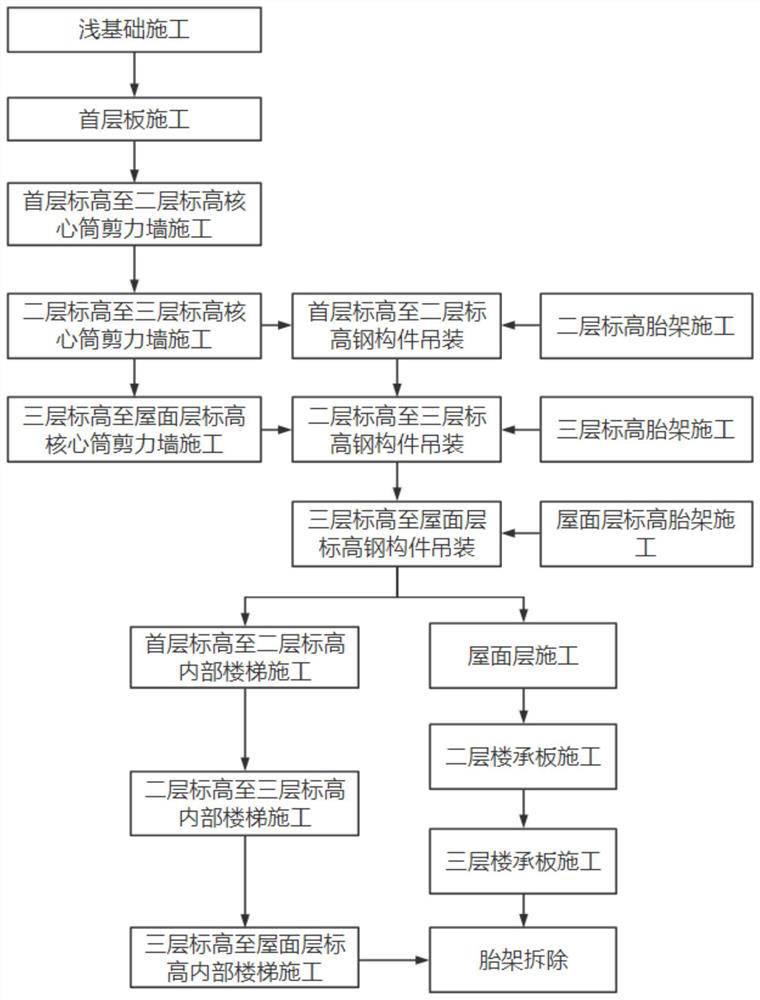

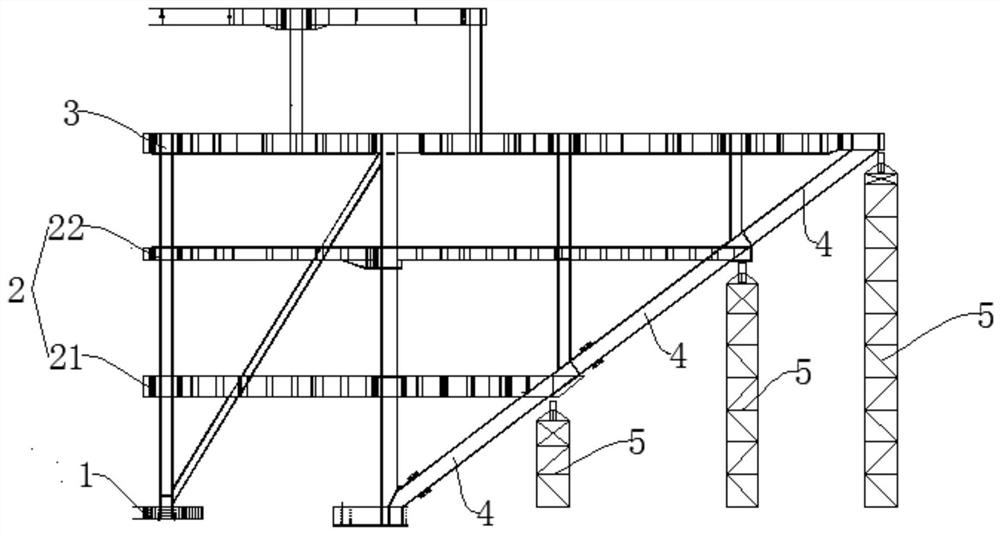

[0037] A construction method that is beneficial for multi-storey special-shaped steel structure buildings to resist horizontal force, including construction of a floor deck, the floor deck includes a first floor deck 1, an intermediate floor deck 2 and a roof layer 3, and the roof deck 3 Prior to the construction of the middle floor deck 2.

[0038] Specifically, taking a three-story special-shaped steel structure building as an example, the special-shaped steel structure building includes a steel frame-core tube shear wall structure, and the middle floor deck 2 includes a second-floor deck 21 and a third-story deck 22, such as Figure 1-2 shown, including the following steps:

[0039] shallow foundation construction

[0040] The foundation of the multi-layer steel frame core tube shear wall structure is the raft foundation under the core tube shear wall structure and the independent foundation under the steel frame column. Since the multi-storey building is small in size a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com