Hydraulic torque converter lock-up clutch sliding friction loss compensation control device and control method

A technology of torque converter and lock-up clutch, applied in transmission, transmission control, fluid transmission, etc., can solve the problem that the friction surface affects the friction material and friction performance of the lock-up clutch, and reduces the service life and reliability of the lock-up clutch. The temperature rise of parts and other problems, to achieve the effect of simple judgment criteria, fast switching, and reducing friction and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

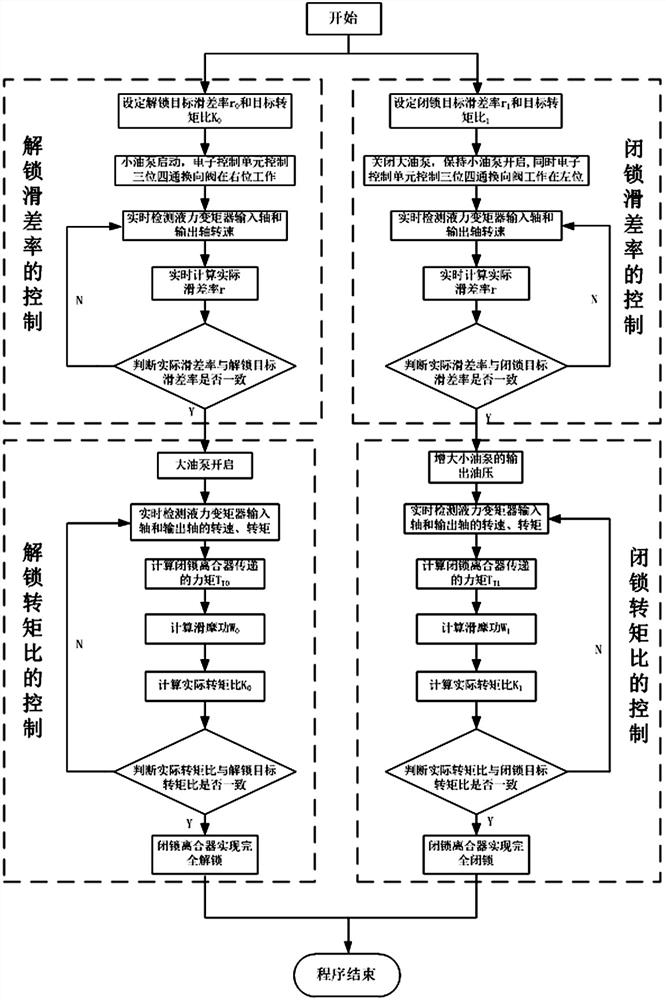

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

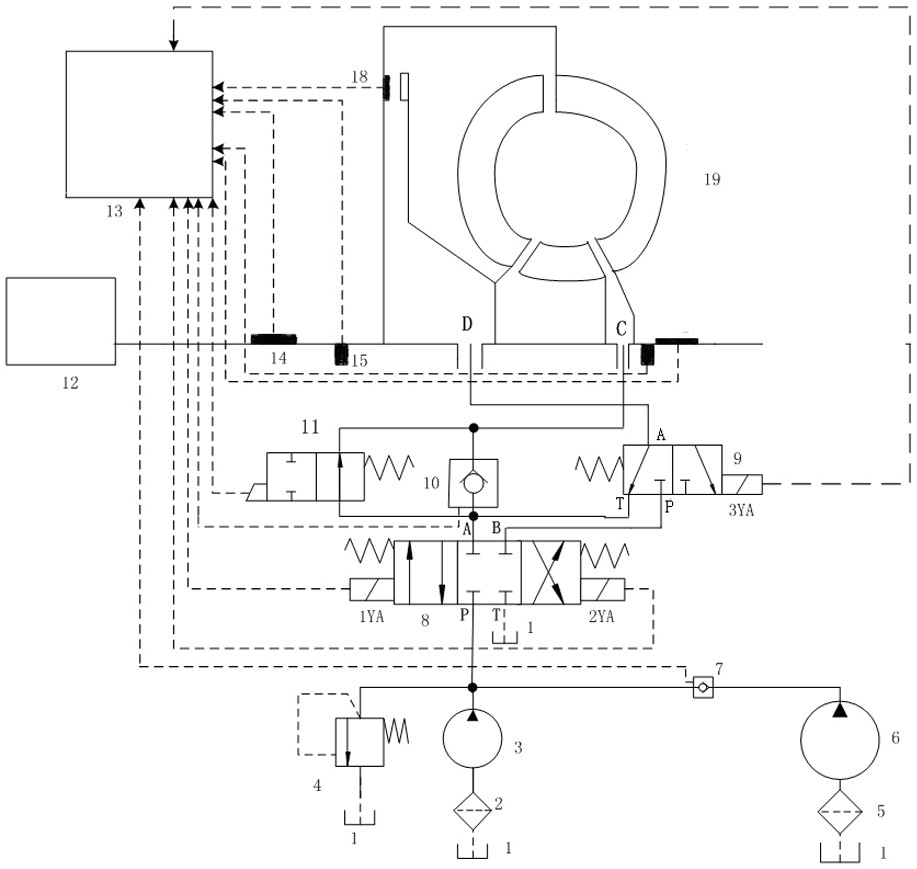

[0037] Such as figure 1 As shown, the hydraulic torque converter lock-up clutch sliding friction loss compensation control device of the present invention includes a hydraulic torque converter 19, a hydraulic device and an electronic control unit 13; the input shaft and the output shaft of the hydraulic torque converter 19 are both A torque sensor 14 and a rotational speed sensor 15 are provided, and a pressure sensor 18 is provided between the lock-up clutch and the housing of the hydraulic torque converter. The input shaft of the torque converter 19 is connected to the engine 12 .

[0038] The hydraulic device includes a fuel tank 1, a small oil pump 3, a large oil pump 6, an overflow valve 4, a three-position four-way reversing valve 8, a stroke valve 11, a one-way valve I7, a one-way valve II10 and a solenoid valve 9; The inlets of the large oil pump 6 and the sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com