Method for measuring alloy feeding distance

An alloy and distance technology, applied in the field of alloys, can solve the problem of inaccurate and complete feeding distance data of aviation magnesium-aluminum alloy materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

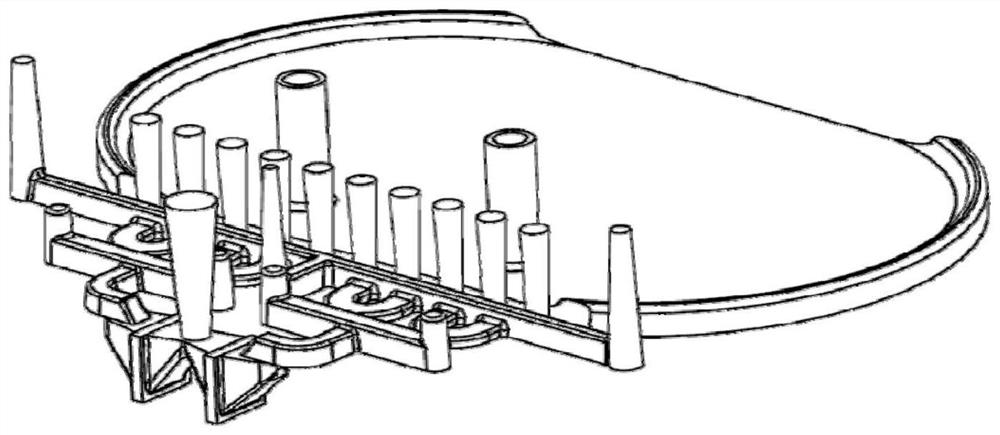

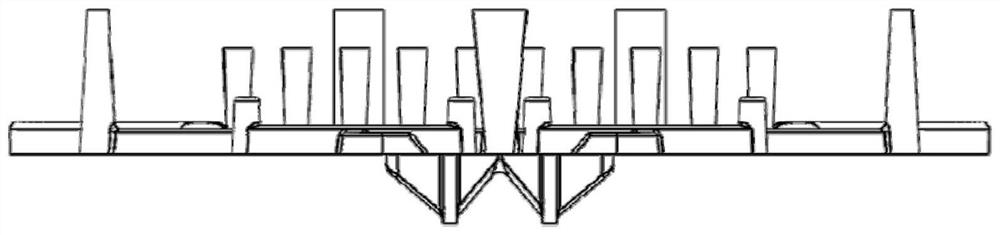

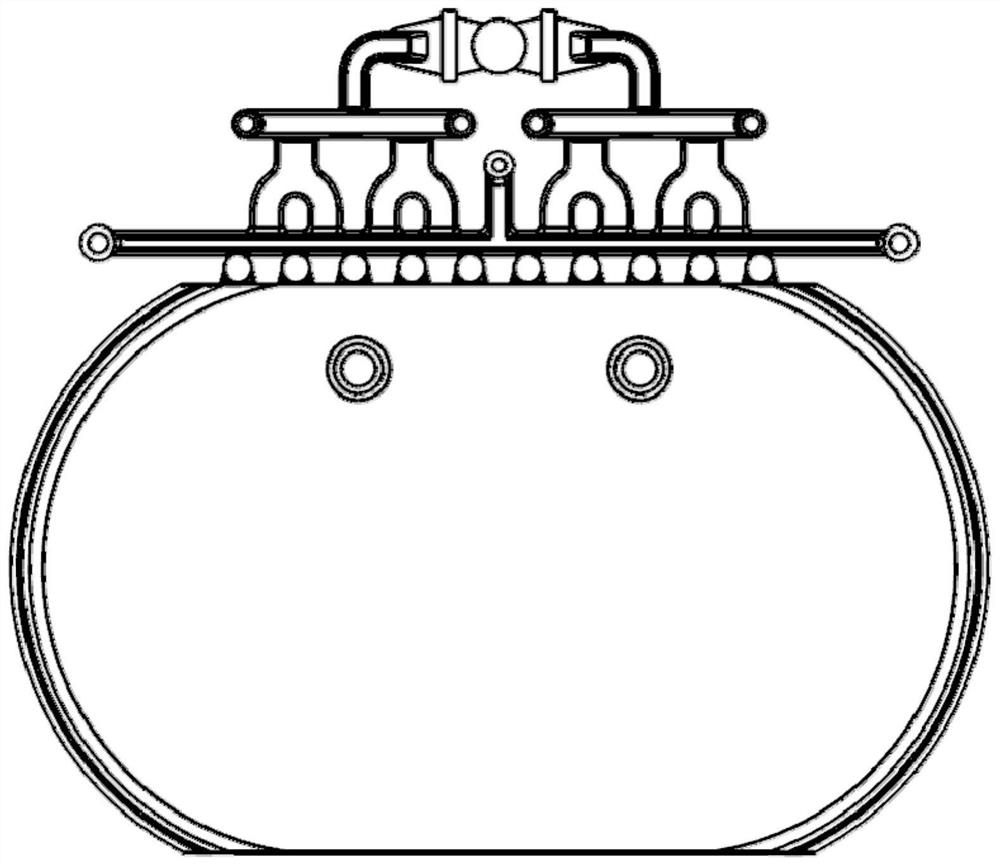

[0037] Image 6 It is a schematic flowchart of the method for measuring the alloy feeding distance provided by the present invention, with reference to FIGS. 1-6 , the method for measuring the alloy feeding distance according to the present invention includes the following steps:

[0038] 1) Design the experimental pouring plan for feeding distance. The experimental pouring plan should ensure that the molten metal flow is filled smoothly, and there are no defects such as entrainment, suffocation, and oxidation, and the final casting is complete;

[0039] 2) Determine the test piece size (specimen thickness), riser size, cold iron position and size specification series required for the experiment, as shown in Table 1;

[0040] Table 1 Dimensions and Specifications Series

[0041]

[0042] 3) Design and manufacture a set of special tooling for feeding distance experiment according to the experimental pouring plan to ensure that the tooling can be used for pouring experiments...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com