High-speed train transmission gear box body strength test method

A technology for strength testing and high-speed trains, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, testing material strength by applying stable tension/pressure, testing of mechanical components, etc., which can solve the problem of increasing fatigue failure and failing to achieve To solve problems such as a single inspection process of gearboxes, etc., to achieve the effect of rigorous process, detailed inspection, and guaranteed production quality and use quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

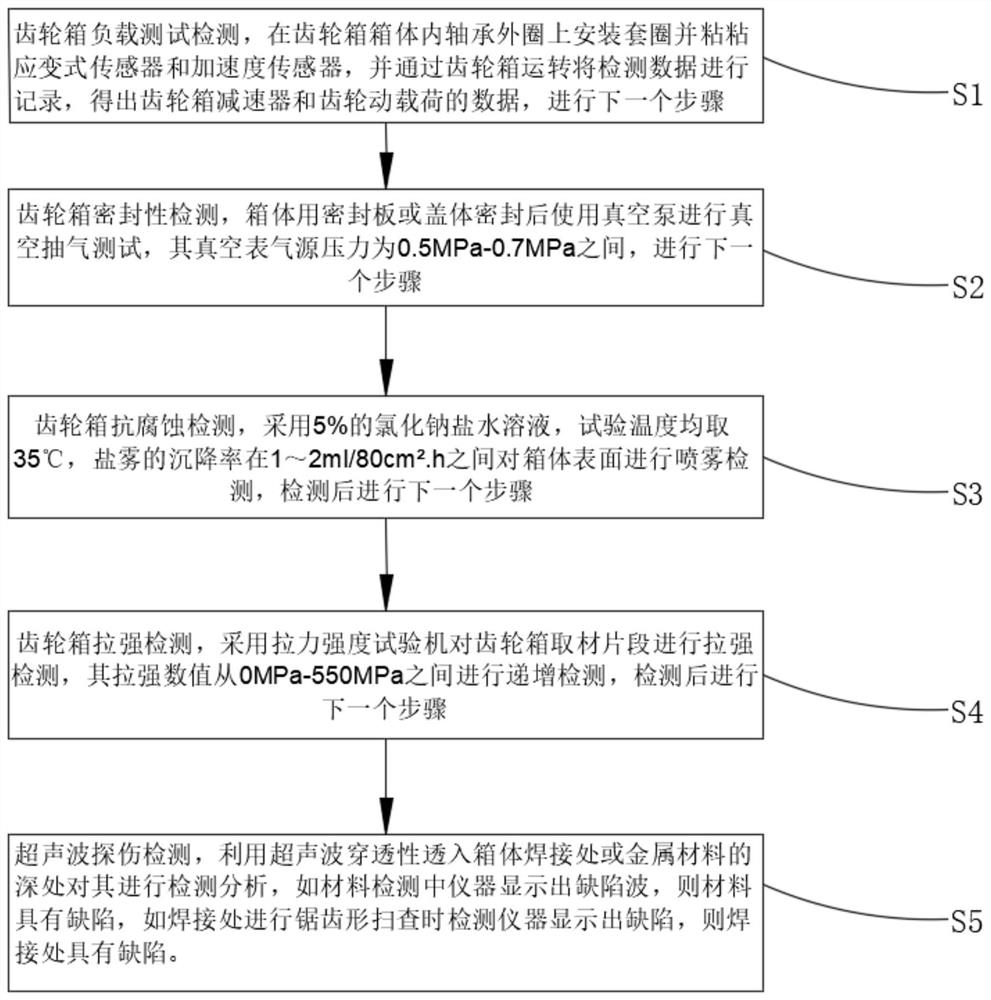

[0022] The present invention provides such figure 1 Shown a kind of high-speed train transmission gear case strength test method, comprises the following steps:

[0023] S1. Gearbox load test detection, install a ferrule on the outer ring of the bearing in the gearbox box and stick the strain sensor and acceleration sensor, and record the detection data through the operation of the gearbox, and obtain the gearbox reducer and gear dynamics. load data, proceed to the next step;

[0024] S2. Check the sealing of the gear box. After the box is sealed with a sealing plate or a cover, use a vacuum pump to perform a vacuum pumping test. The air source pressure of the vacuum gauge is 0.6MPa, and proceed to the next step;

[0025] S3. The corrosion resistance test of the gear box adopts 5% sodium chloride saline solution, the test temperature is 35°C, and the sedimentation rate of salt spray is 1.5ml / 80cm 2 Spray detection on the surface of the box between .h, and proceed to the next...

Embodiment 2

[0047] The present invention provides such figure 1 Shown a kind of high-speed train transmission gear case strength test method, comprises the following steps:

[0048] S1. Gearbox load test detection, install a ferrule on the outer ring of the bearing in the gearbox box and stick the strain sensor and acceleration sensor, and record the detection data through the operation of the gearbox, and obtain the gearbox reducer and gear dynamics. load data, proceed to the next step;

[0049] S2. Gear box sealing test. After the box body is sealed with a sealing plate or a cover body, a vacuum pump is used for vacuum pumping test. When the air source pressure of the vacuum gauge is 0.5MPa, proceed to the next step;

[0050] S3. The corrosion resistance test of the gear box adopts 5% sodium chloride saline solution, the test temperature is 35°C, and the sedimentation rate of the salt spray is 1 / 80cm 2 Spray detection on the surface of the box between .h, and proceed to the next step ...

Embodiment 3

[0072] The present invention provides such figure 1 Shown a kind of high-speed train transmission gear case strength test method, comprises the following steps:

[0073] S1. Gearbox load test detection, install a ferrule on the outer ring of the bearing in the gearbox box and stick the strain sensor and acceleration sensor, and record the detection data through the operation of the gearbox, and obtain the gearbox reducer and gear dynamics. load data, proceed to the next step;

[0074] S2. Check the sealing performance of the gear box. After the box is sealed with a sealing plate or a cover, use a vacuum pump to perform a vacuum pumping test. The air source pressure of the vacuum gauge is 0.7MPa, and proceed to the next step;

[0075] S3. Gearbox anti-corrosion test, using 5% sodium chloride saline solution, the test temperature is 35°C, and the sedimentation rate of salt spray is 2ml / 80cm 2 Spray detection on the surface of the box between .h, and proceed to the next step af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com