A kind of display circuit board and its manufacturing method, led display screen

A technology of LED display screen and display circuit, which is applied in the direction of circuits, electrical components, electric solid devices, etc. It can solve the problems of bulky structure and low pixels, achieve high circuit precision, solve current voltage drop and signal attenuation, and reduce drilling The effect of the amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

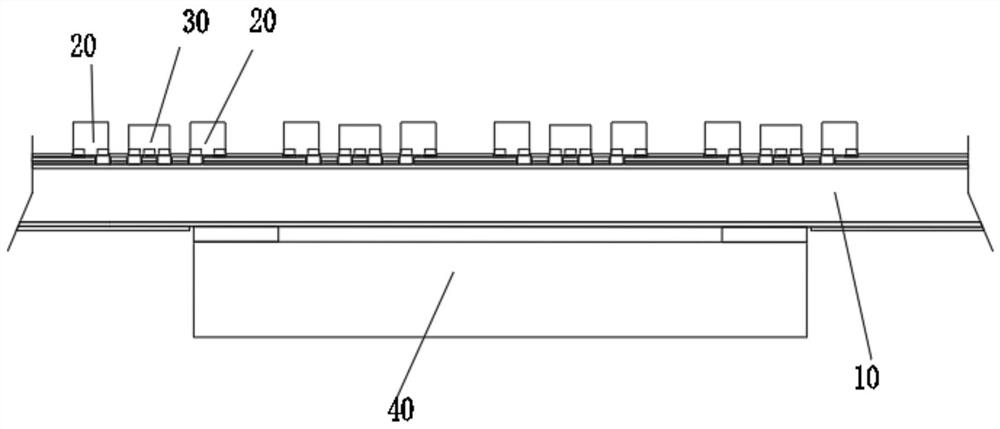

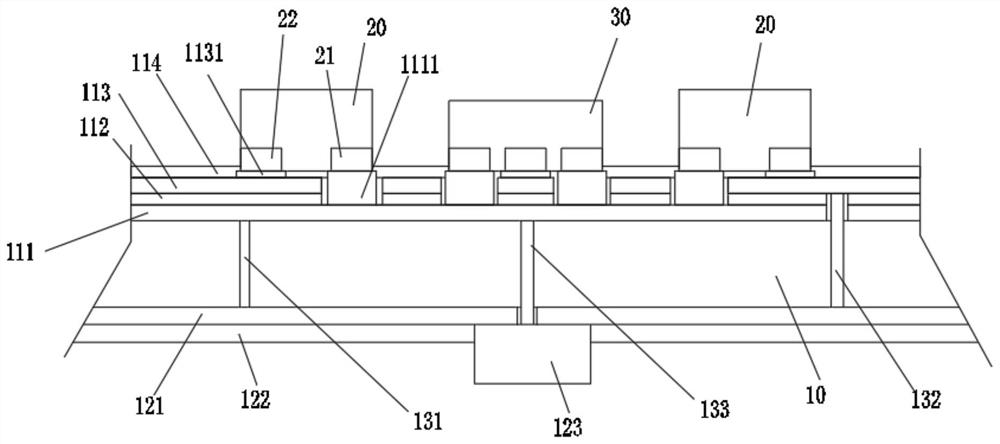

[0053] Embodiment 1 of the present invention provides a display circuit board. see Figure 1 to Figure 3 , the display circuit board includes a glass substrate 10 , a plurality of flip-chip bare-chip LED light-emitting chips 20 , a plurality of bare-chip constant current drive chips 30 and a control element 40 .

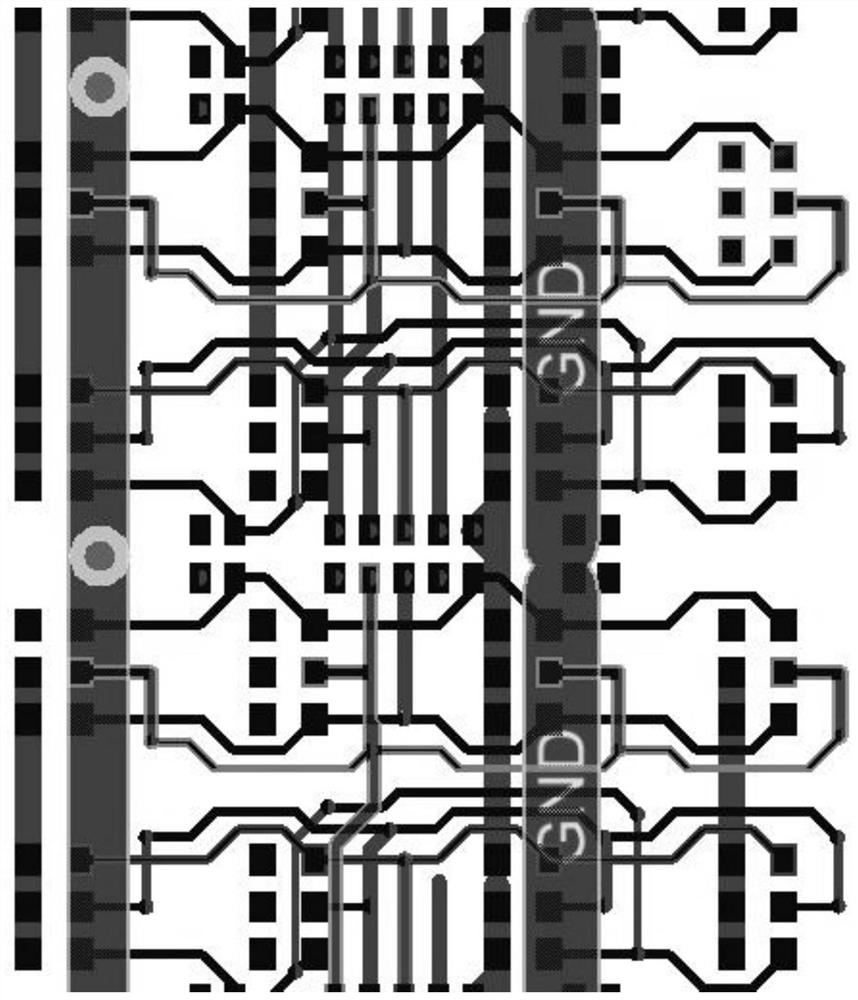

[0054]The glass substrate 10 can be a TFT glass substrate with a thickness of 0.3 mm to 2.0 mm, and its front is provided with a first circuit layer 111 , an intermediate insulating layer 112 , a second circuit layer 113 and a first surface insulating layer 114 in sequence. A third circuit layer 121 and a second surface insulating layer 122 are provided on the back of the glass substrate 10 .

[0055] In practical applications, the thickness of the insulating layer is about 0.1um-10um, and the thickness of the circuit layer is about 1um-35um.

[0056] The glass substrate 10 is also provided with a plurality of conductive holes (such as the first conductive hole 131...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com