Plate surface dust removal device and using method thereof

A technology of a dust removal device and a dust suction device, which is applied in the directions of cleaning methods using gas flow, removing smoke and dust, cleaning methods and utensils, etc., can solve the problems of dusty working environment pollution, inability to effectively remove debris, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

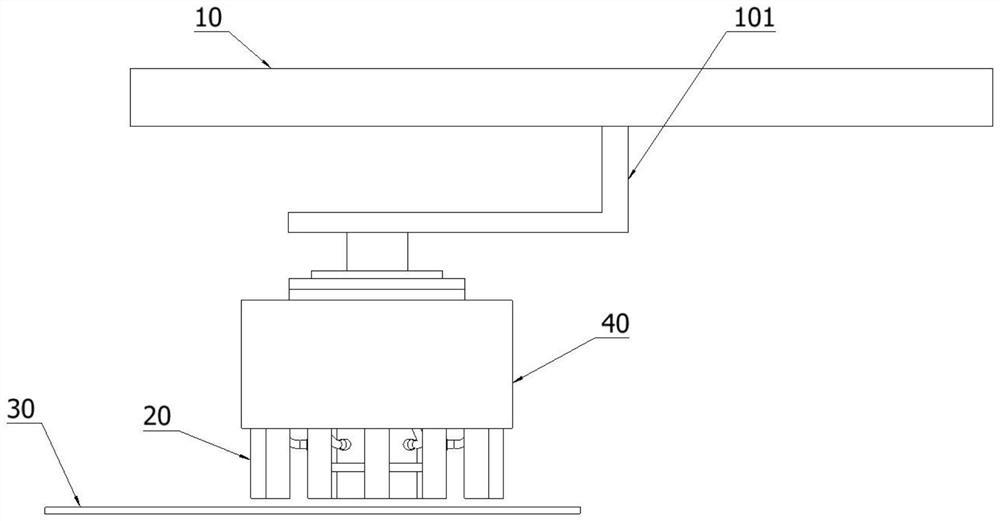

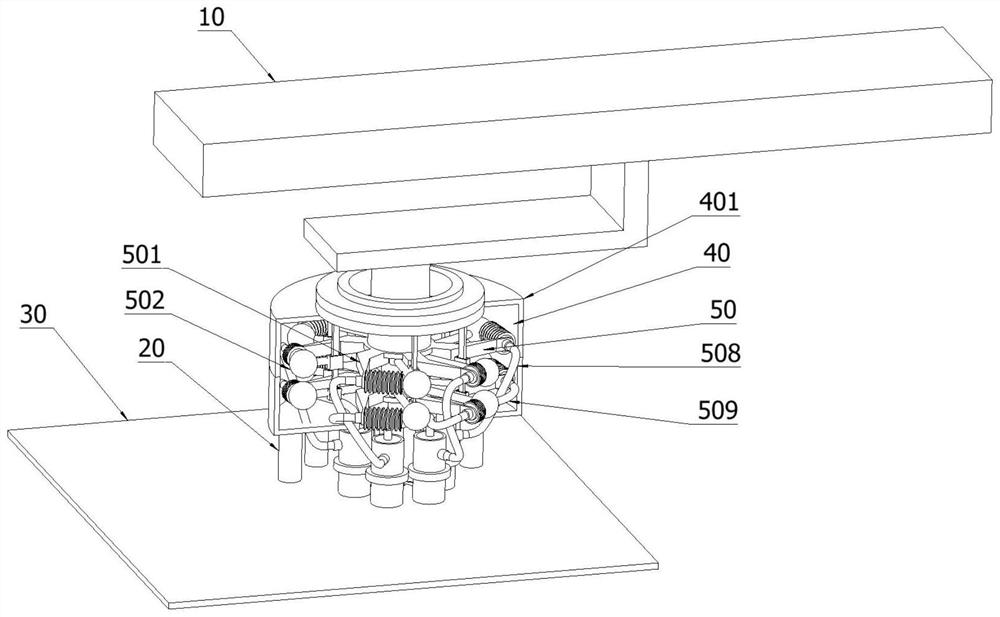

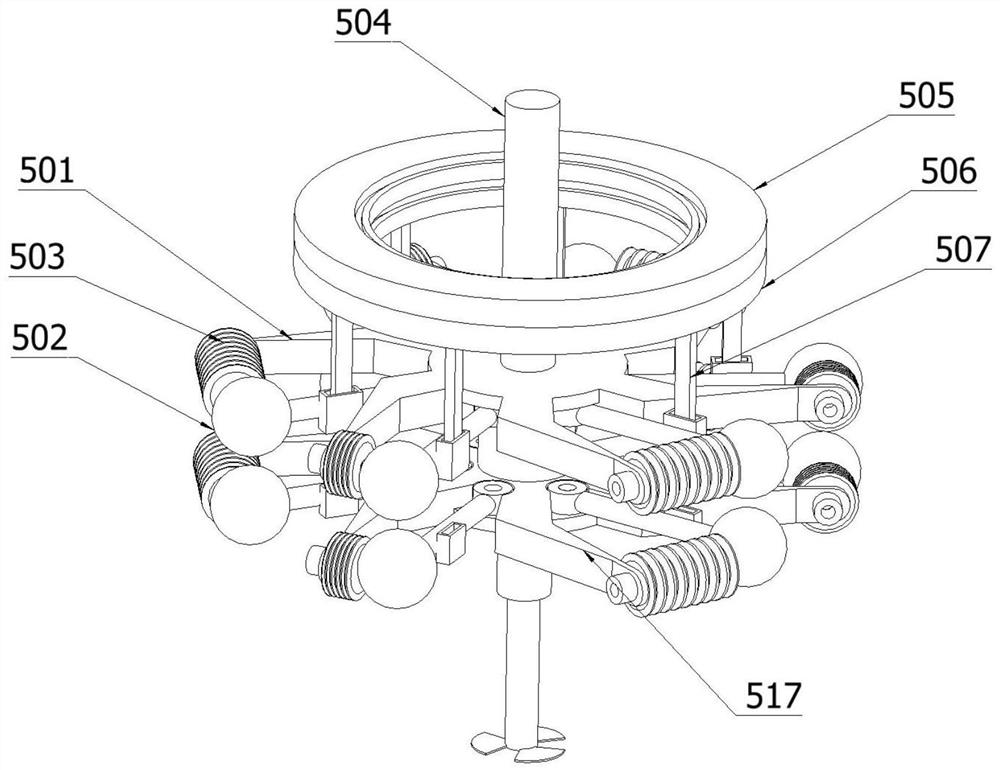

[0041] Such as figure 1 , 2 As shown, this embodiment discloses a dust removal device for the surface of a plate 30, including: a body 10, the body 10 is arranged on a plane, and the body 10 includes: a main frame, the main frame is arranged on a plane, and a translation module is arranged inside the main frame , the translation module is fixedly connected with the main frame; the mobile frame 101, the mobile frame 101 is arranged on the lower surface of the main frame, the mobile frame 101 is connected with the translation module, and the mobile frame 101 moves along the extension direction of the main frame through the translation module; The carrying device 40, the carrying device 40 is arranged below the mobile frame 101, the carrying device 40 is fixedly connected with the mobile frame 101, the carrying device 40 includes: a housing case 401, the interior of the housing case 401 is hollow, and the housing case 401 is located under the mobile frame 101 , there is a gap be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com