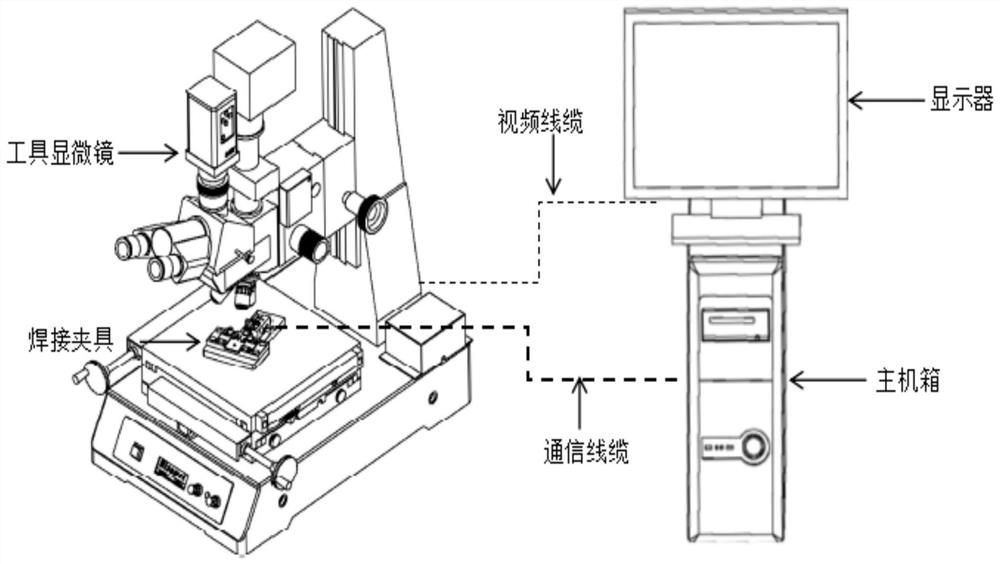

Soldering assembly fixture for qsp28 module flexible soft board

An assembly fixture and flexible technology, applied in the field of optical communication, can solve problems such as insufficient manual welding accuracy, achieve the effect of improving product consistency, sufficient performance, and solving large differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

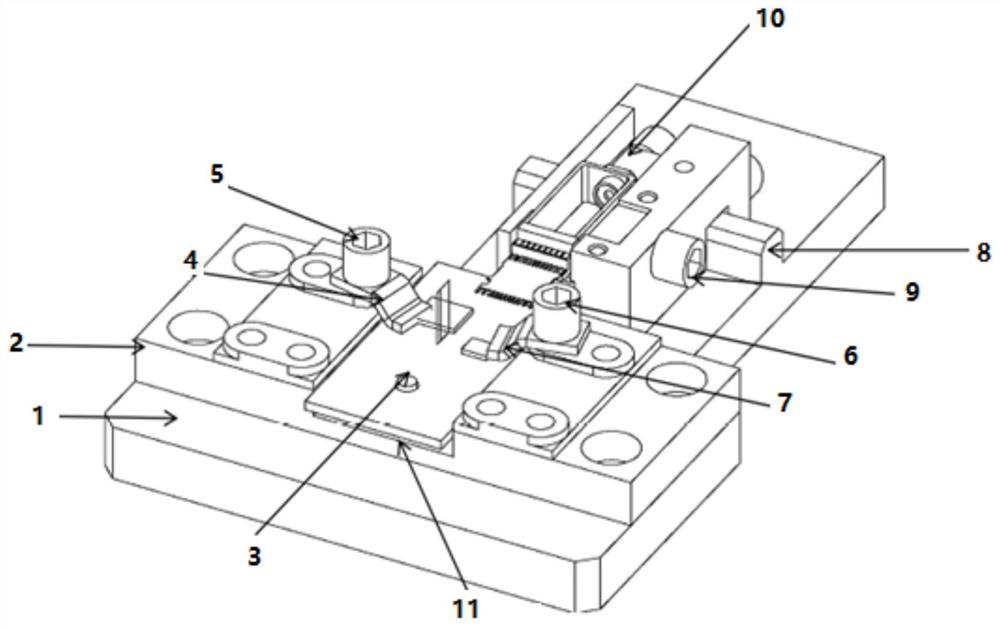

[0013] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings and technical solutions.

[0014] A welding assembly fixture for QSP28 module flexible soft board, comprising a base 1, an adjustable base 2, a PCBA positioning column 3, a first PCBA fixing clip 4, a first PCBA locking device 5, and a second PCBA locking device 6 , the second PCBA fixing clip 7, the boss slide rail 8, the device locking device 9, the device card slot 10 and the PCBA card slot 11;

[0015] The base 1 is of a T-shaped structure, and the vertical plate is provided with a boss slide rail 8 with an integrated structure, and the device slot 10 is matched with the boss slide rail 8; according to requirements, the device slot 10 is on the boss slide rail 8 Slide to adjust the position of the device;

[0016] The adjustable base 2 is fixed on the horizontal plate of the base 1, and a PCBA card slot 11 is opened at the middle position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com