Clamping assembly for producing copper pipe

A technology for clamping components and copper tubes, which is applied in vices, manufacturing tools, etc., can solve problems such as inability to fix clamps, copper tube rotation, and insufficient clamping of copper tubes, so as to avoid clamp shaking, increase friction, and replace Convenient and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

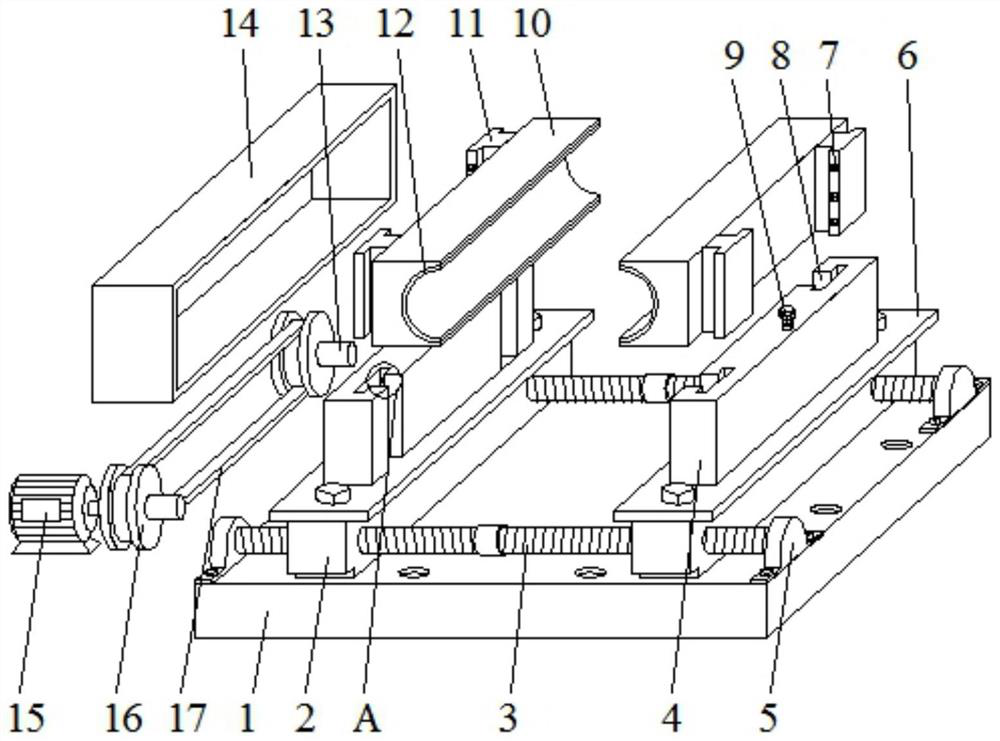

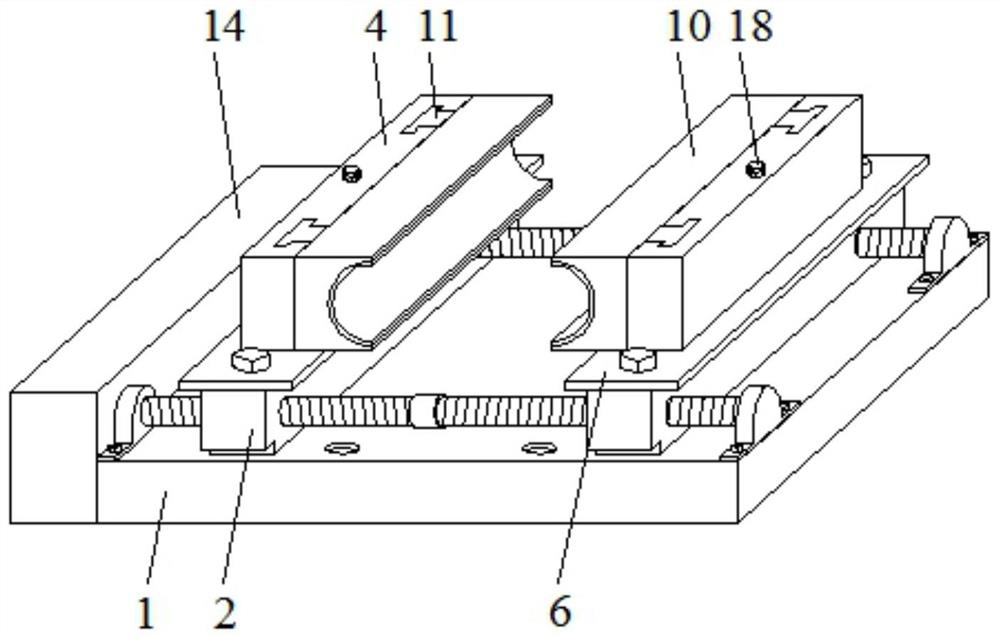

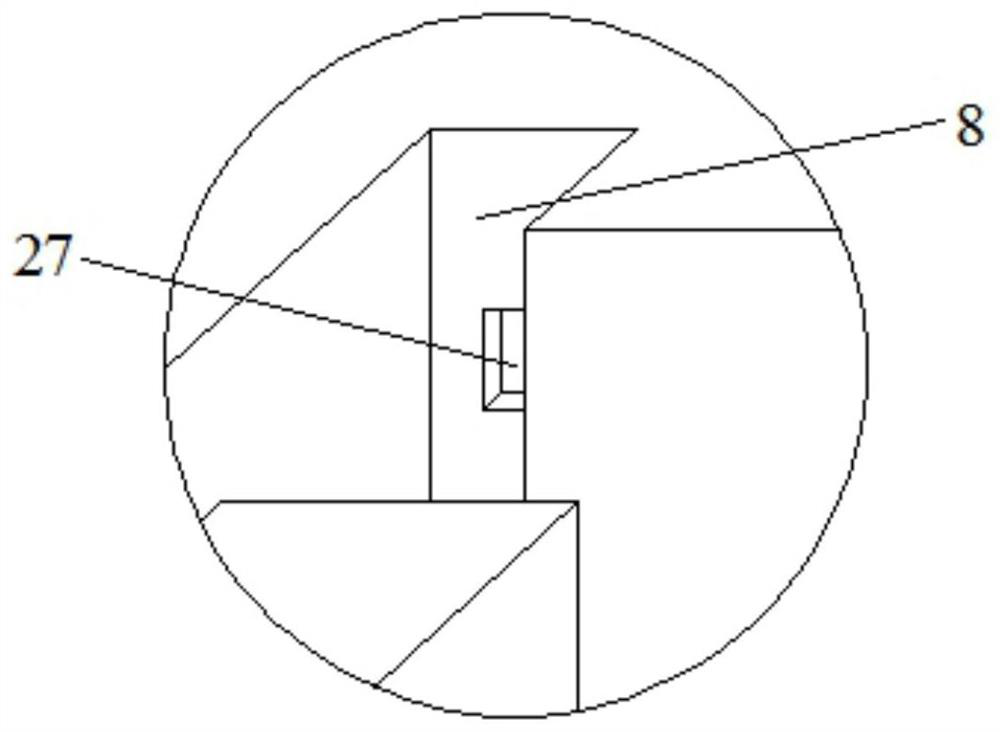

[0028] refer to Figure 1-4 , a clamping assembly for producing copper pipes, including a base plate 1, a box body 14 and a slide plate 2, the box body 14 is welded horizontally to one side of the base plate 1, and there are two slide plates 2 that are horizontally slidably connected to the top of the base plate 1, and the base plate The top of 1 is equipped with a synchronous movement mechanism for synchronously moving the two slides 2, and the structures of the tops of the two slides 2 are identical and symmetrically arranged, and the top of the slides 2 is horizontally connected with a top plate 6 by bolts, and the center of the top of the top plate 6 is welded vertically There is a hollow plate 4, one side of the hollow plate 4 is slidably connected with a fixture 10, and both ends of the fixture 10 close to the hollow plate 4 are vertically welded with T-shaped blocks 11, and the two ends of the side of the hollow plate 4 close to the fixture 10 There are T-shaped slots 8...

Embodiment 2

[0037] refer to Figure 5 , a clamping assembly for producing copper pipes. Compared with Embodiment 1, this embodiment differs only in that the rotating mechanism includes a first gear 19, and there are two first gears 19 that are vertically rotatably connected to the box body 14 Inside, the same second gear 20 is meshed between the opposite sides of the two first gears 19, and the second gear 20 is vertically rotatably connected to the inside of the box body 14, and a second positive and negative gear is installed horizontally on one side of the box body 14. motor 21, and the top end of the output shaft of the second reversible motor 21 is welded to the center of one side of the second gear 20.

[0038] The working principle of this embodiment: in actual use, the second gear 20 is driven to rotate by the second positive and negative motor 21, the second gear 20 drives the two first gears 19 to rotate, and the two first gears 19 drive the two rotating rods 13 rotates, the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com