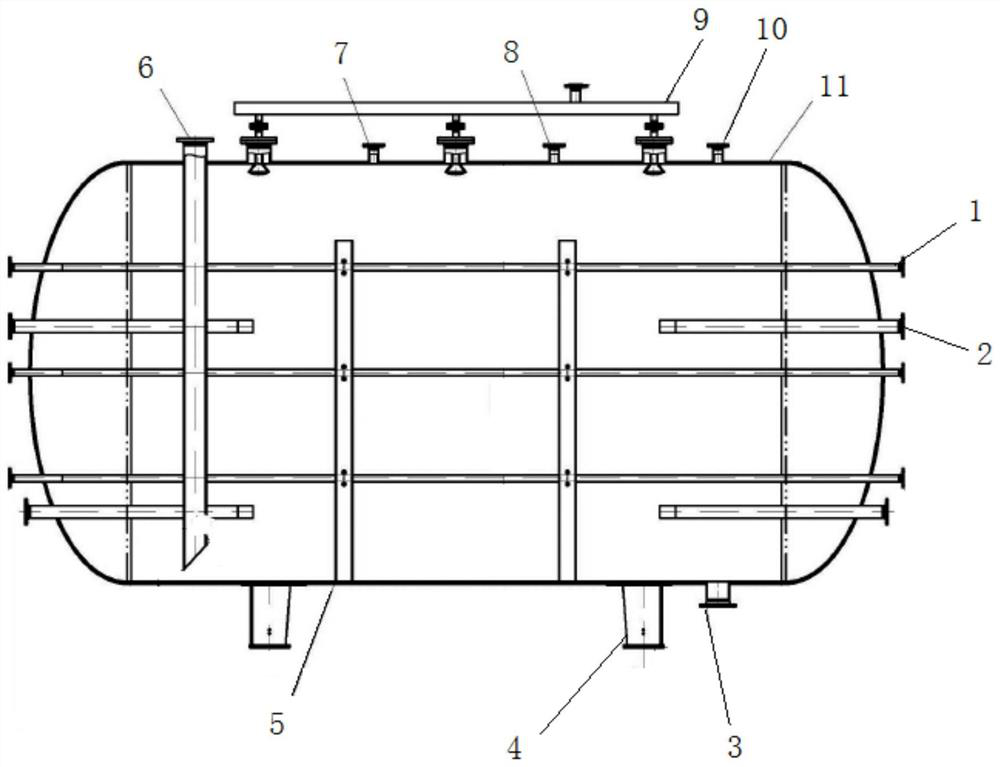

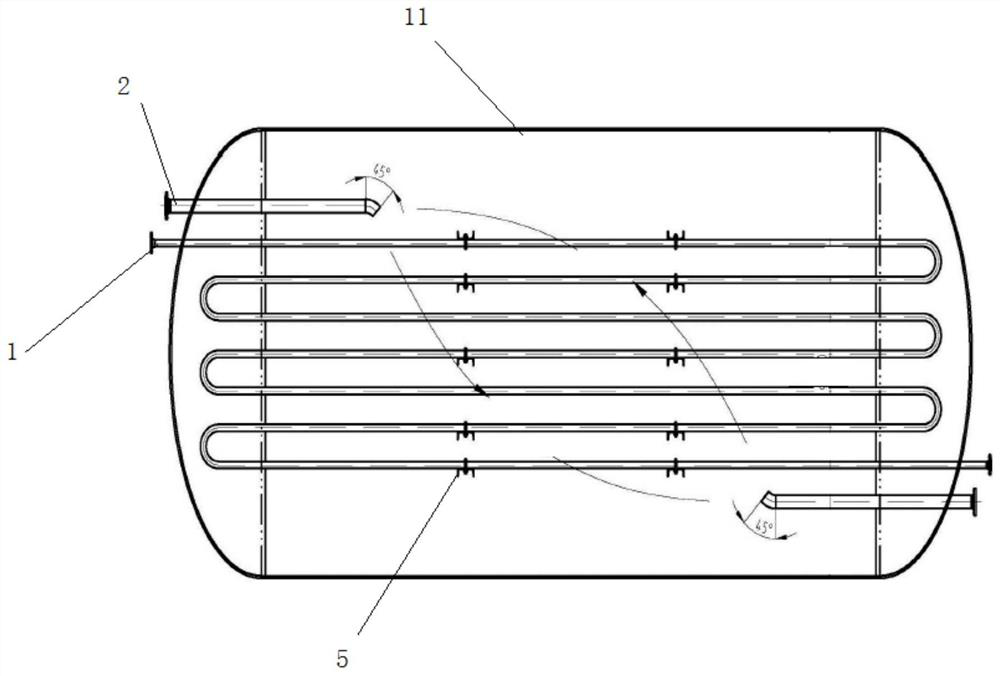

Large horizontal ammonium nitrate solution storage tank

An ammonium nitrate solution, horizontal technology, applied in large containers, tank trucks, transport buses, etc., can solve the problems of reducing the effective volume of the solution, uneven solution concentration, small rain contact area, etc., to achieve fewer layers and lower temperature The effect of too high and low requirements for conveying head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment proposes a large horizontal ammonium nitrate solution storage tank, its structure see figure 1with figure 2 As shown, it includes a tank body 11 supported by a support 4, and a feed port 6, a discharge port 3, a heating mechanism and a rain shower mechanism 9 arranged on the tank body 11, and the tank body 11 is also provided with The backflow circulation mechanism, the backflow circulation mechanism is composed of two sets of backflow circulation components arranged along the height direction of the tank body 11, and each set of backflow circulation components is composed of two backflow circulation pipes 2 installed diagonally in the axial direction of the tank body 11. One end of the return circulation pipe 2 protrudes from the tank body 11 and is connected to an external return line. The return line is also connected to the feed port 6 and is used to discharge part of the material discharged from the discharge port 3. The outlets of the two return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com