Multi-steam source hybrid low-pressure heater and its heating and deaeration boiler water supply system in power station

A technology for low-pressure heaters and boiler feed water, applied in feed water heaters, lighting and heating equipment, preheating, etc., can solve problems such as redundancy and weakening of oxygen removal functions, and achieve improved utilization, reduced head requirements, and simplified processes The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

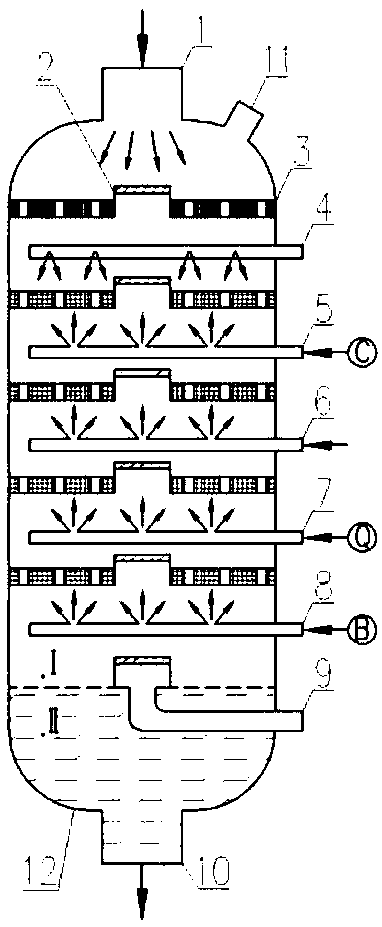

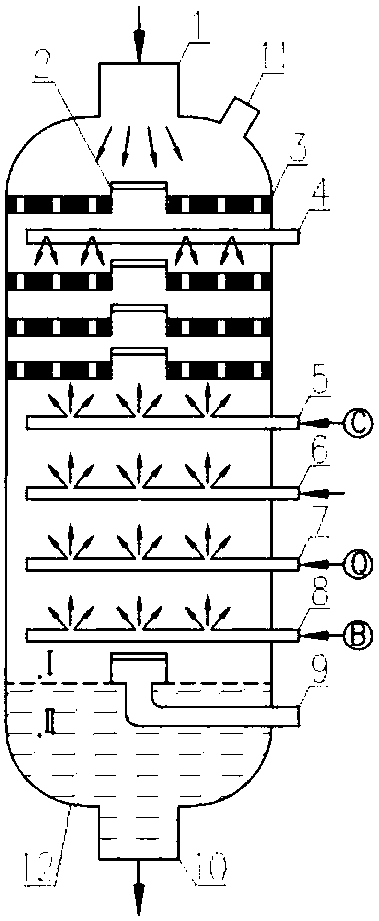

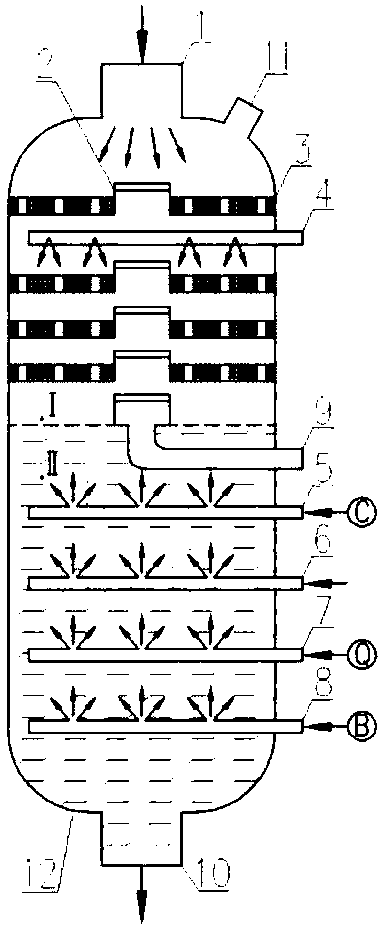

[0066] The multi-steam source hybrid low-pressure heater of the present invention mainly includes: main condensate inlet 1, overflow orifice plate 2, porous water tank 3, hydrophobic and porous spray pipe 4, shaft seal leaking steam porous release pipe 5, low-temperature reheating steam Porous release pipe 6, porous release pipe 7 for low-temperature reheat steam, porous release pipe 8 for high-temperature and low-pressure steam such as leakage of door lever, condensate overflow pipe 9, condensate outlet 10, and housing 12.

[0067] The main condensed water inlet 1 is provided on the top of the housing 12, the condensed water outlet 10 is provided at the bottom, and the non-condensable gas discharge port 11 is also provided on the housing 12, as shown in Figure 1 (a), in the housing A plurality of porous water tanks 3 are arranged inside the body, and the plurality of porous water tanks 3 are arranged sequentially from top to bottom in the housing, and porous discharge pipes ar...

Embodiment 2

[0079] The multi-steam source hybrid low-pressure heater heating and deaeration boiler water supply system of the present invention mainly includes: boiler S1; steam turbine high-pressure cylinder S2; medium-pressure cylinder S3; low-pressure cylinder S4; generator S5; condenser S6; condensate pump S7 ; Multi-steam source hybrid low-pressure heater S8; secondary condensate pump S9; surface type medium and low pressure heater S10; boiler feed water pump S11; regulating valve S12; Device S15; external steam cooler S16; relay pump S17; the specific connection relationship is as follows:

[0080] After the outlet of the condenser S6 is connected in series with the condensate pump S7, it is connected with the main condensate inlet 1 of the multi-steam source hybrid low-pressure heater S8, and the condensate outlet 10 of the multi-steam source hybrid low-pressure heater S8 is connected in series with the secondary condensate pump S9 It is connected in series with the multi-stage sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com