A process water regulating tank repair system and repair method

A technology for repairing systems and regulating pools, applied in chemical instruments and methods, building maintenance, water/sewage treatment, etc., can solve problems such as economic loss, difficulty, time-consuming, etc., achieve low lift requirements, prevent danger, and connect reliably. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

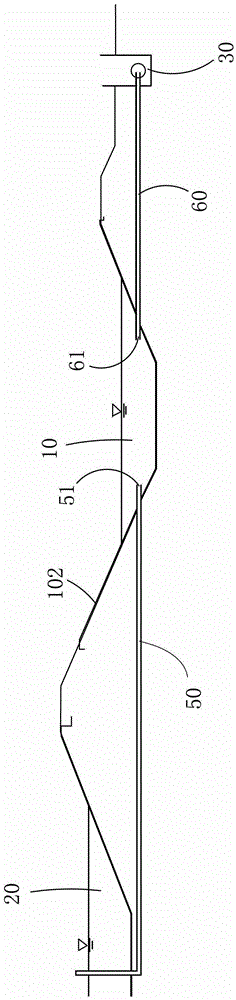

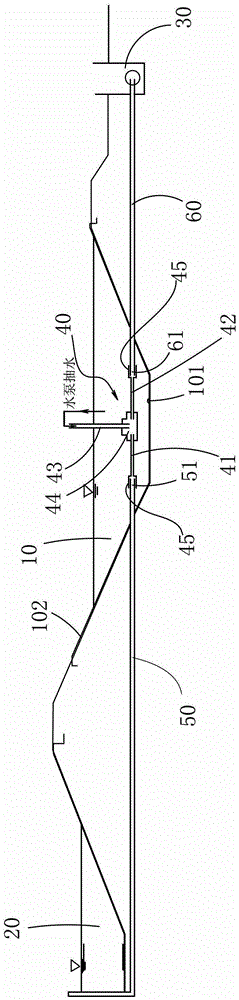

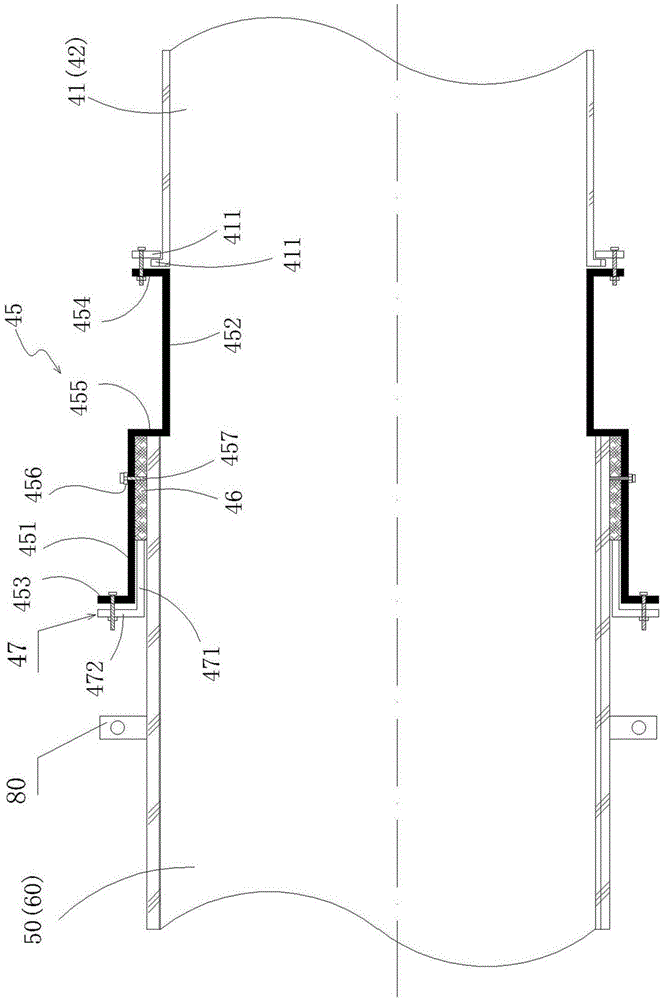

[0039] Such as Figure 2-3As shown, in a process water regulating tank repair system of the present invention, the regulating tank 10 communicates with the bottom of the storage area 20 through the first delivery pipe 50, and the process water in the storage area is introduced into the water inlet 51 of the first delivery pipe 50 for adjustment. pool, and the regulating pool is also communicated with the return water pump room 30 that pumps the process water back to the factory through the second delivery pipe 60, and the process water is exported from the water outlet 61 of the second delivery pipe 60 to the regulating pool. As the conveying pipes, the first conveying pipe and the second conveying pipe can be HDPE pipes or PE pipes. For process water with high pollutant concentration, high-density polyethylene pipes (HDPE pipes) are generally required. figure 2 The anti-seepage film 102 of the regulating tank wall in the center has a leakage point 101. In order to drain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com