Glass cover plate and preparation method thereof, display panel and display device

A glass cover plate and ultra-thin glass technology, applied in glass manufacturing equipment, glass cutting devices, glass production, etc., can solve the problems of poor surface indexing and hardness, different distances, different thicknesses of functional layers, and different properties. Achieve the effect of improving production yield, good mechanical properties, and thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

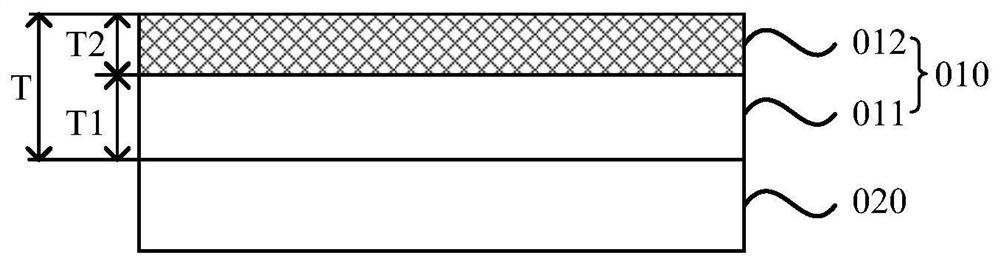

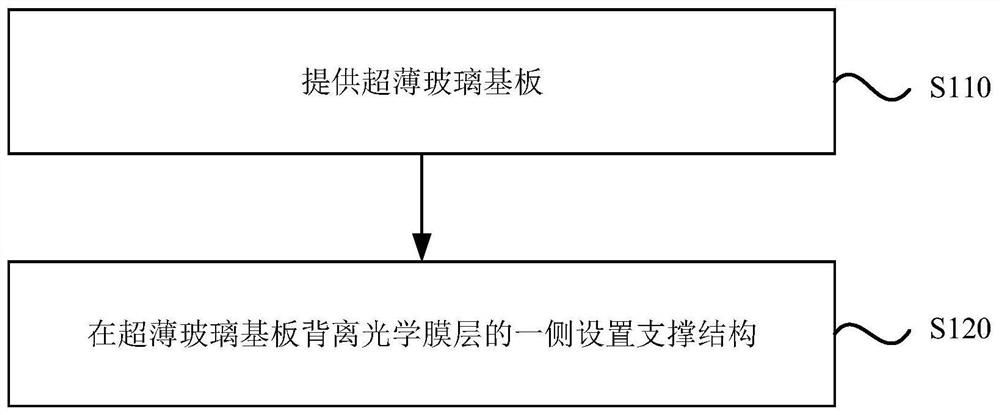

[0040] In order to solve the above technical problems, an embodiment of the present invention provides a method for preparing a glass cover, which is used to prepare the glass cover provided by the embodiment of the present invention. image 3 It is a flowchart of a method for preparing a glass cover plate provided by an embodiment of the present invention. Such as image 3 Shown, the preparation method of this glass cover plate comprises:

[0041] S110, providing an ultra-thin glass substrate; one side of the ultra-thin glass substrate is formed with an optical film layer in a roll-to-roll manner;

[0042] S120, setting a support structure on a side of the ultra-thin glass substrate away from the optical film layer.

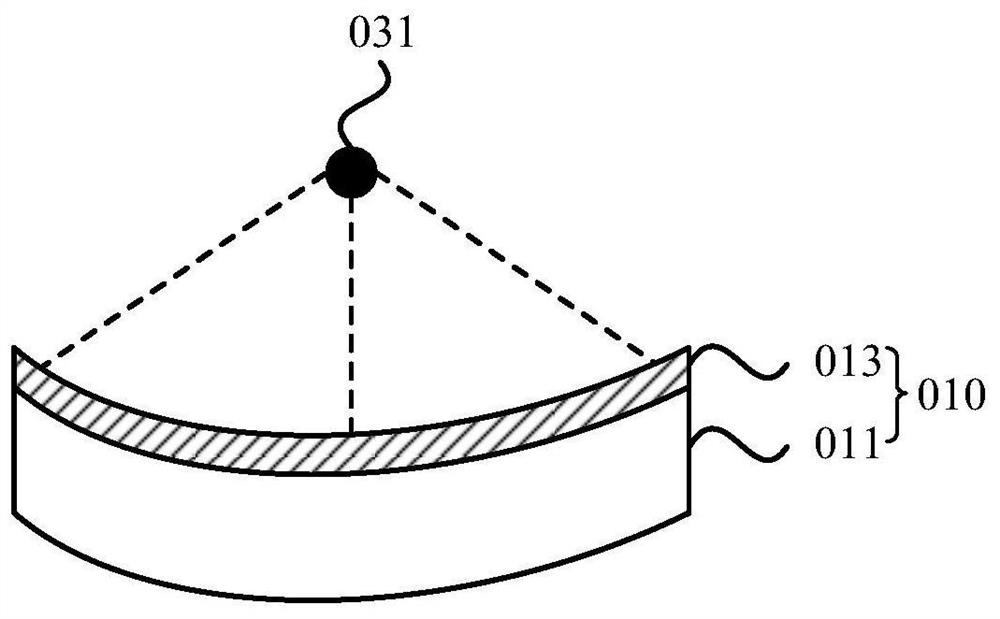

[0043] in, Figure 4 With image 3 A structural schematic diagram of a corresponding preparation process of a glass cover plate. Such as Figure 4As shown, the ultra-thin glass substrate 11 is wound on the roller shaft 21 of the roll-to-roll equipment, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com