Self-cleaning system of air-jet loom

An air-jet loom, self-cleaning technology, used in textiles, textiles and auxiliary equipment for papermaking and weaving, etc., can solve the problems of increased cleaning volume and difficulty, a large amount of dust and cloth debris, inconvenient installation and disassembly, etc. Increase the difficulty of cleaning, the effect of undertaking is good, and the effect of being easy to undertake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

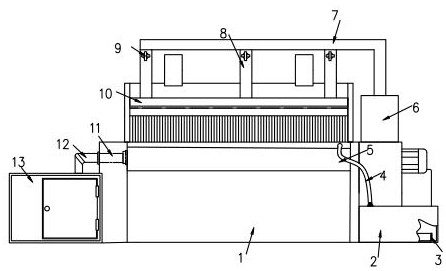

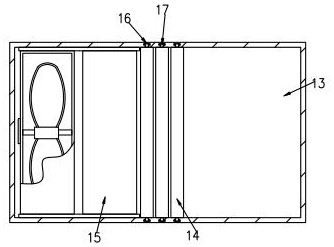

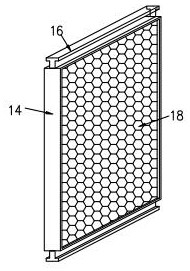

[0039] Such as figure 1 , figure 2 and image 3 shown;

[0040] figure 1 It is a structural schematic diagram of the present invention;

[0041] figure 2 It is the installation diagram of collection box, filter plate and blower fan in the present invention;

[0042] image 3 It is the installation diagram of the filter plate, slide block and filter layer in the present invention;

[0043] A self-cleaning system for an air-jet loom, comprising a connection pipe 12 installed on the left side of the air-jet loom 1, a collection box 13 connected to the end surface of the connection pipe 12, and a plurality of filter plates 14 installed in the middle of the collection box 13 The inside of the collection box 13 is equipped with a fan 15 near the left side of the filter plate 14, the top and bottom of the filter plate 14 are symmetrically fixed with a slide block 16, the inside of the collection box 13 is symmetrically provided with a chute 17, the top and bottom of the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com