Intensive spray type yarn steaming machine

A yarn steaming machine, intensive technology, applied in the field of textile manufacturing, can solve the problems affecting the steaming treatment of yarn or fabric, steam concentration, etc., achieve uniform temperature and humidity inside and outside the yarn, avoid temperature difference, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further described and understood by non-limiting examples below.

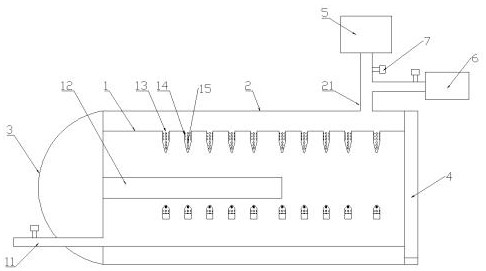

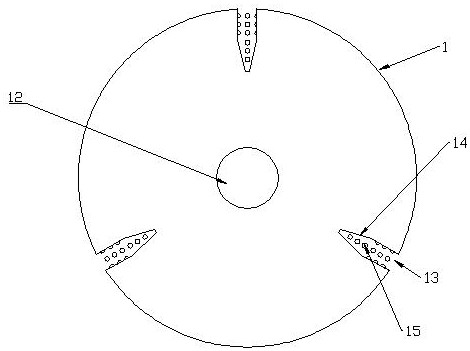

[0015] The invention is a spray-intensive yarn steaming machine, which includes a steaming cylinder, which includes an inner cylinder 1 and an outer cylinder 2, one end of the inner cylinder 1 and the outer cylinder 2 is fixedly connected with a cover plate 3, and the other end is hinged There is an end cover 4, and the outer cylinder 2 is provided with an air inlet pipe 21, and a cavity for accommodating steam is formed between the inner cylinder 1 and the outer cylinder 2, and the air inlet pipe 21 is respectively connected to the vacuum pump 5, The heating water tank 6, the vacuum pump 5, and the heating water tank 6 are all provided with pipeline valves 7, and the inner cylinder 1 is provided with an air outlet pipeline 11, and the air outlet pipeline 11 is provided with a pipeline valve 7; During work, open the end cover 4, the bobbin is sleeved on the fixed axis 12, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com