Unexploded ammunition/explosive destruction protection device, system and method

A technology for unexploded bombs and explosives, applied in the field of unexploded bombs/explosives destruction protective equipment, can solve the problems of high quality steel explosion-proof equipment and easy secondary damage, and achieve the effect of rapid emergency treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a protective equipment for destroying unexploded bombs / explosives, which adopts a modular assembly structure, and can quickly dispose of explosives and military unexploded ammunition without causing secondary damage.

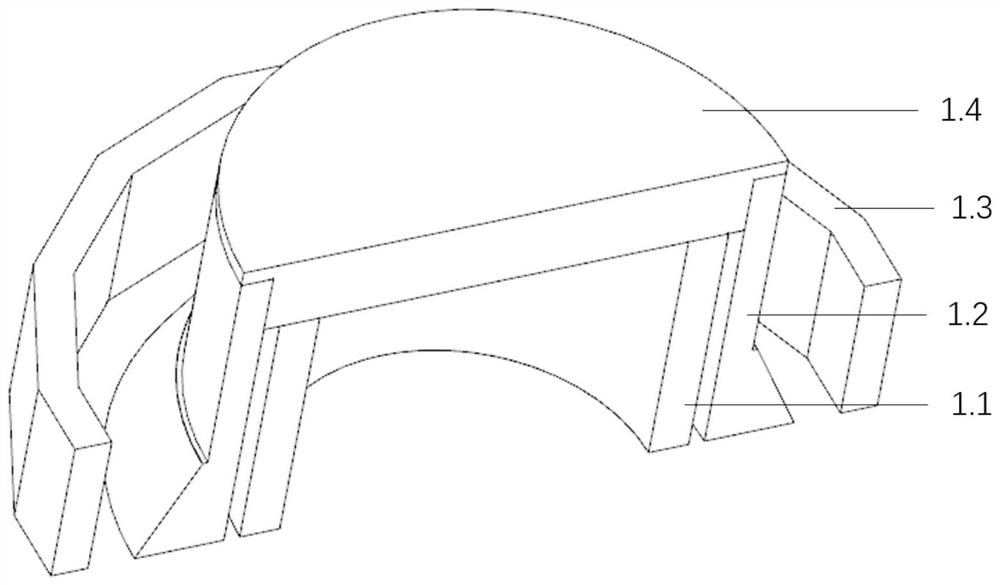

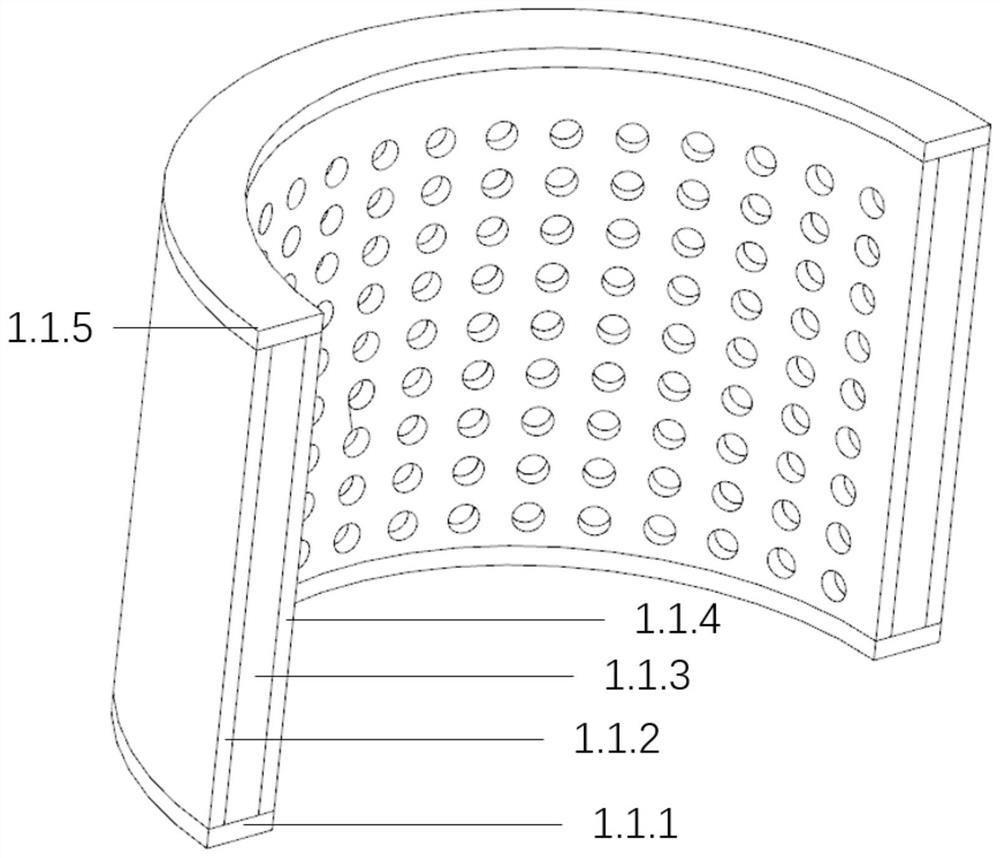

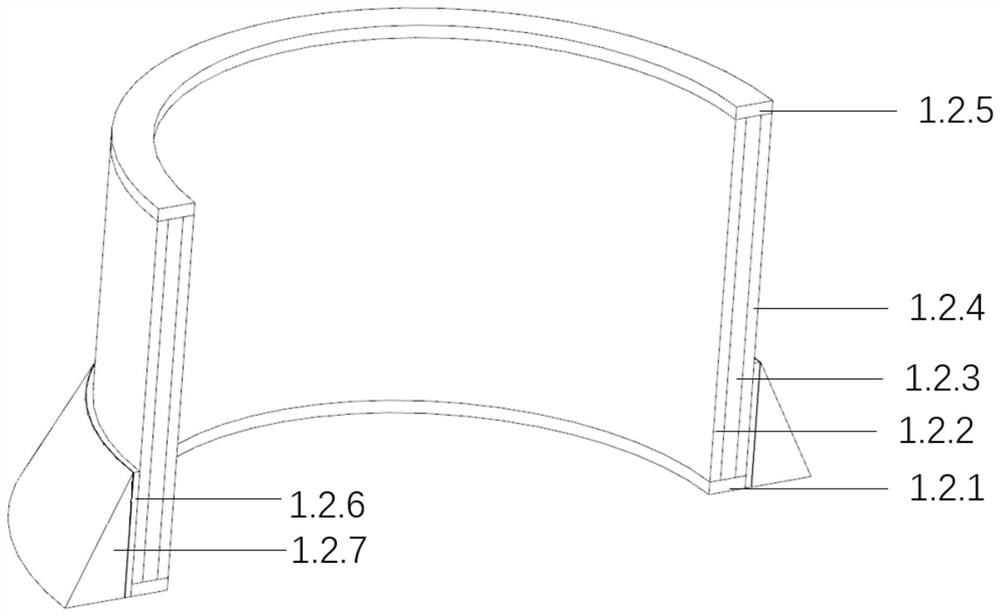

[0046] Such as figure 1 As shown, the equipment for destroying unexploded ordnance / explosives includes four modules, namely: inner fence 1.1, outer fence 1.2, anti-leakage fence 1.3 and top cover 1.4. The inner fence 1.1 and the outer fence 1.2 are cylindrical structures with openings at both ends, wherein the inner fence 1.1 is straight cylindrical (equal diameter), and the outer fence 1.2 includes a tapered section and a straight cylindrical section connected to the small end of the tapered section, and the tapered The section is located below the straight section; the inner fence 1.1 is coaxially set inside the outer fence 1.2, and there is a gap between the two; the top cover 1.4 is installed at the top opening of the inner fe...

Embodiment 2

[0055] This embodiment provides a system for destroying unexploded bombs / explosives, such as Figure 6 As shown, the unexploded bomb / explosives destruction system includes the protective equipment 1, the support frame 2 and the water cannon 3 in the above-mentioned embodiment 1; the water cannon 3 can be a common model in the market.

[0056] The support frame 2 adopts a hollow steel pipe, which is used to support and position the water cannon 3; The holes protrude into the interior of the inner fence 1.1 of the protective equipment 1, whereby unexploded bombs / explosives placed in the protective equipment 1 can be destroyed by the water cannon.

[0057] Since the protective equipment 1 is a separate type, that is, a modular assembly structure, when destroying the unexploded bombs / explosives, the protective equipment 1 can be assembled directly on site without moving the unexploded bombs / explosives, and the unexploded bombs / explosives The cover is installed inside the inner fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com