Detection device and method for detecting air tightness of canned food

A detection device, canned food technology, applied in the direction of fluid tightness test, measuring device, liquid tightness measurement using liquid/vacuum degree, etc., can solve the problems of product qualification rate reduction, pollution, deterioration, etc., and achieve a solution Effects of microbial contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

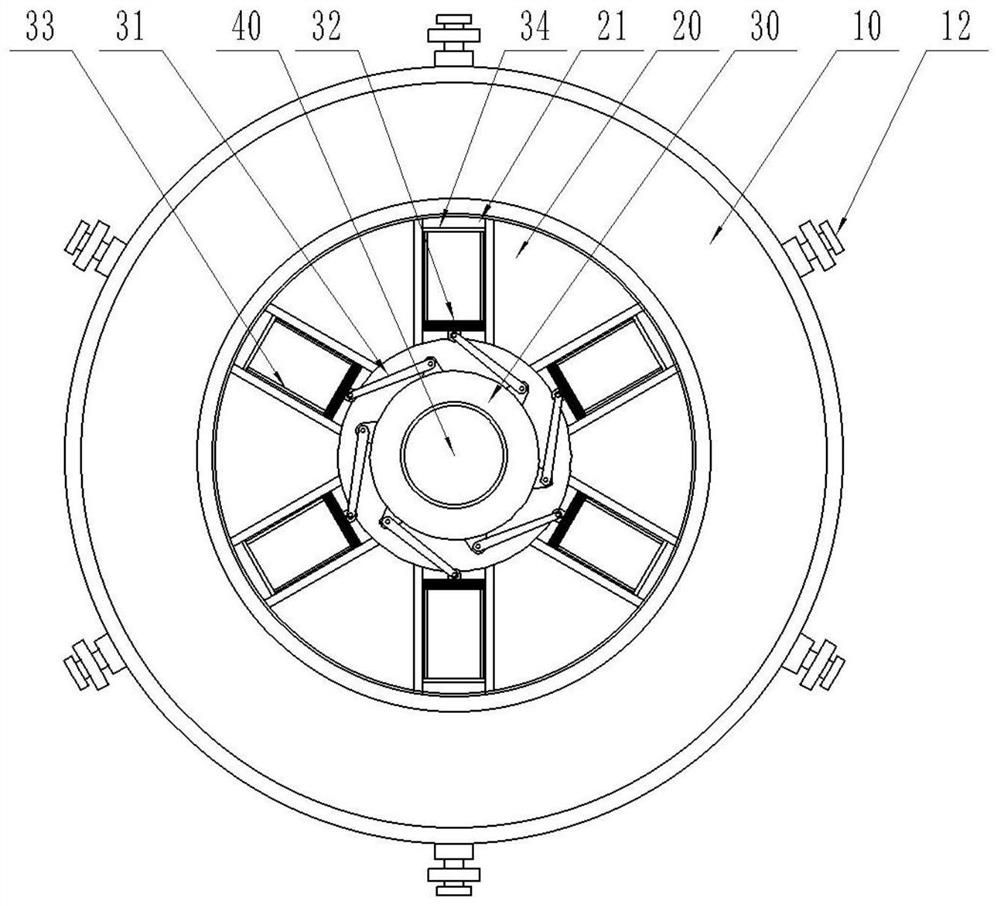

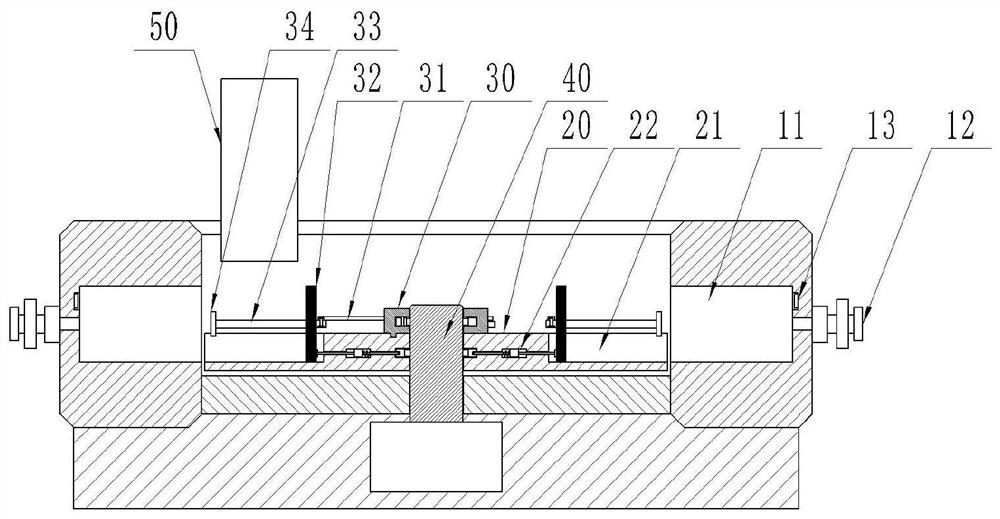

[0065] A detection device for detecting the airtightness of canned food, wherein, such as figure 1 As shown, it includes: a detection mechanism 10 , a docking mechanism 20 , a push-pull mechanism 30 , and a rotating column 40 .

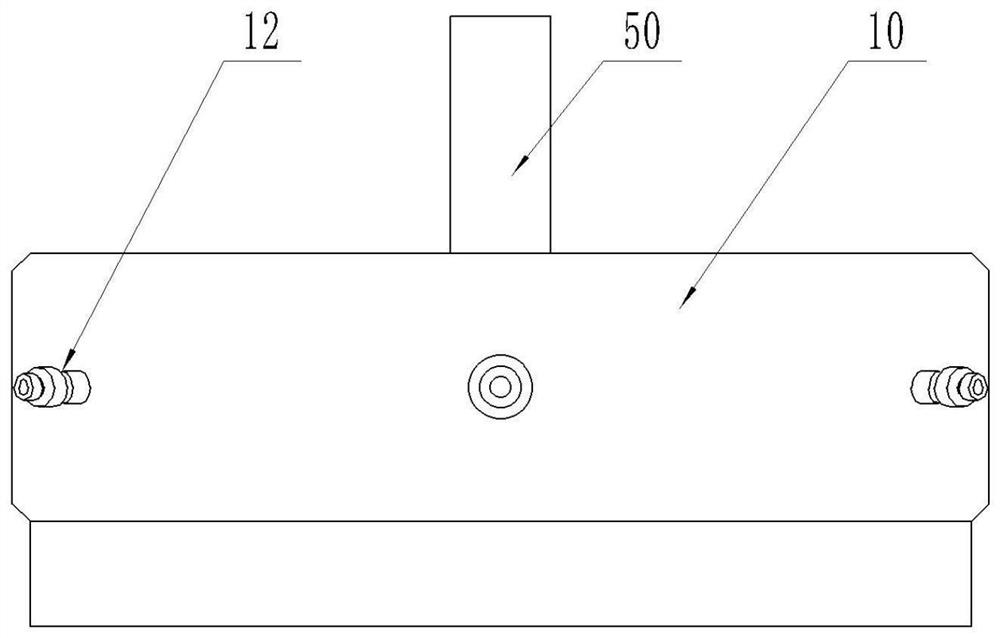

[0066] Such as figure 2 , 3 As shown, the detection mechanism 10 is an annular hollow structure, and the detection mechanism 10 has a detection cavity 11 and a pressurization interface 12 . The detection chamber 11 is a semi-closed structure. The boost ports are radially distributed on the outer surface of the detection mechanism 10 , and the boost ports 12 communicate with the detection chamber 11 .

[0067] Such as image 3 , 4 As shown, the docking mechanism 20 is installed in the detection mechanism 10 , and the docking mechanism 20 is rotatably connected to the detection mechanism 10 .

[0068] The outer disk is a hollow structure, and slideways 21 are radially distributed on the outer disk, and the slideway 21 can correspond to and cooper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com