Frangible small article falling sample speed reduction device and manufacturing method thereof

A technology for deceleration devices and small items, applied in radiation measurement, instruments, luminescent dosimeters, etc., can solve the problems of large experimental errors, failure to reach the release temperature, loose temperature, etc., achieve good toughness and elasticity, and increase reliability , Fishing line smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

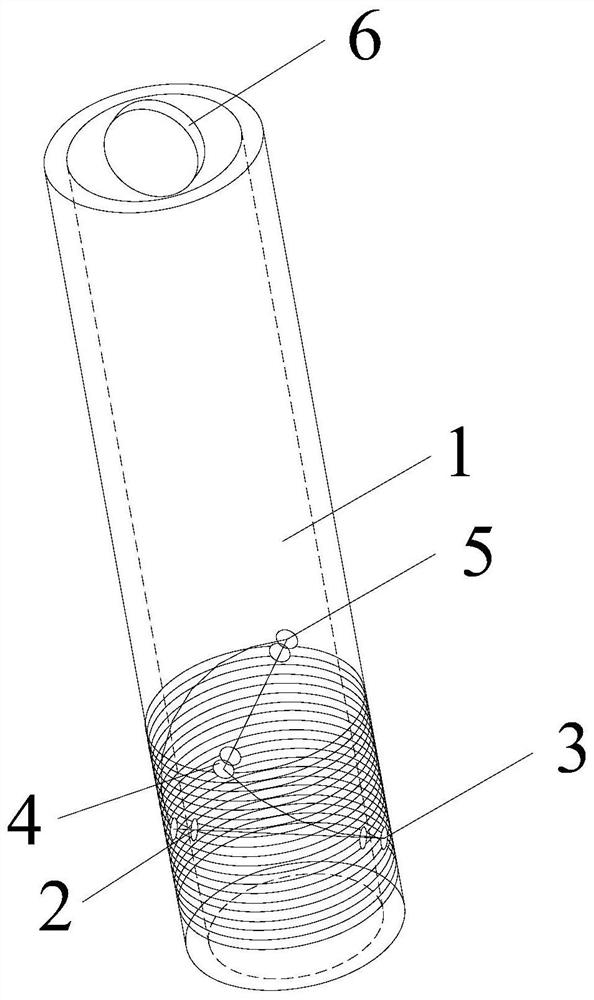

[0022] see figure 1 , according to an embodiment of the present invention, a drop-off deceleration device for fragile small items includes a metal pipe main body 1, a heating plate is provided on the bottom side of the metal pipe main body 1, on the same horizontal line near the end of the heating plate on the metal pipe main body 1 Two opposite holes A2 and hole B3 are provided, and two opposite holes C4 and hole D5 are provided on the metal pipe main body 1 at a certain distance perpendicular to the connection line between hole A2 and hole B3 at the upper end of hole A2 and hole B3 , inside the hole A2, hole B3, hole C4 and hole D5 are wound with fishing line in sequence, and the opening end of the metal pipe main body 1 is covered with a silicone soft cover.

[0023] In addition, the top of the metal pipe main body 1 is provided with a sample 6, and the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com