Industrial intelligent control system based on software definition

An intelligent control system, software-defined technology, applied in software design, software maintenance/management, etc., can solve the problems of high implementation cost, lack, and difficulty in transformation, so as to improve service capabilities, improve utilization, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

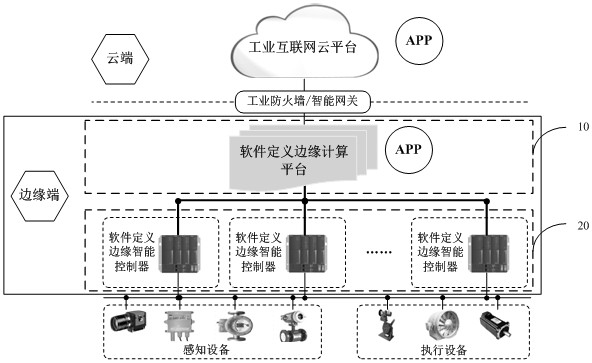

[0030] This application provides a software-defined industrial intelligent control system, such as figure 1 As shown, the whole is a "device-edge-cloud" collaborative architecture system, in which the cloud is the cloud, and the industrial Internet platform in the cloud provides intelligent management of production and operation, industrial intelligence, big data services and other capabilities, providing edge-end industrial intelligence Control empowerment; the edge is the edge end, which is the core for realizing industrial intelligent control, including the software-defined edge computing platform 10 and the software-defined edge intelligent controller 20; the end is the terminal, and the terminal mainly includes sensing devices and execution devices.

[0031] The purpose of this application is to provide a software-defined industrial intelligent control system to meet the business requirements and technical challenges of industrial intelligent control.

[0032] The technic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com