Design method of LTCC substrate embedded resistor with adjustable value

A design method and technology of buried resistance, which are applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of difficulty in meeting the requirements of use and low precision, and achieve the effect of improving integration and yield, and improving yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

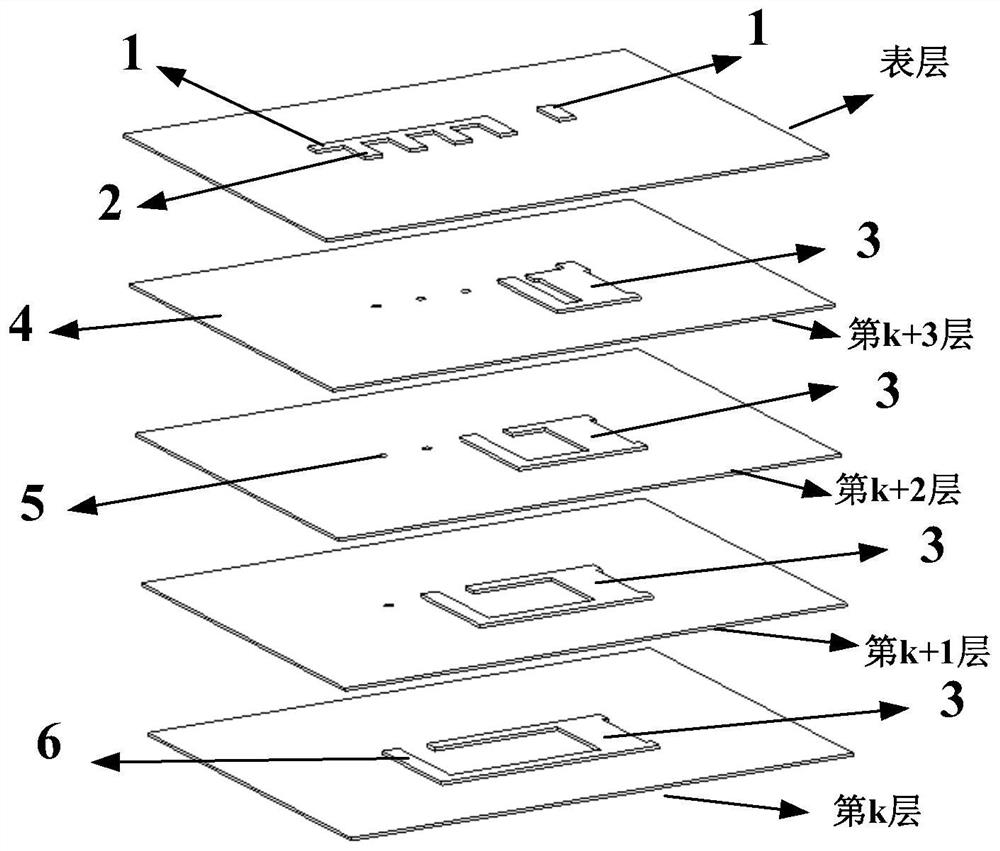

Image

Examples

Embodiment 2

[0026] In the circuit design of the second embodiment, it is necessary to embed a 130Ω resistor in the LTCC substrate, and the precision of the resistance value after adjustment is required to be controlled within ±10%.

[0027] The concrete steps of this embodiment are as follows:

[0028] Step 1. According to the historical production big data of the current process, calculate the resistance value accuracy range of the embedded resistance of a certain LTCC production line ±30%;

[0029] Step 2. Calculate the actual designed resistance value R=100Ω according to the required resistance value R0=130Ω;

[0030] Step 3: Divide the difference between 2 times R0 and R into 3 parts, that is, R1=20Ω. The calculated accuracy range is only ±13.8%, which does not meet the design requirements, so it is necessary to continue to connect the resistors in series. After calculation, on the basis of connecting three R1s in series, one R2=12Ω can be connected in series to meet the accuracy ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com