Super retarded concrete and its preparation method

A concrete and ultra-retarding technology, applied in chemical instruments and methods, grain processing, solid separation, etc., can solve the problems of less grinding times, inconsistent material particle size, insufficient grinding, etc., to improve efficiency, ensure stability and The effect of service life and damage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

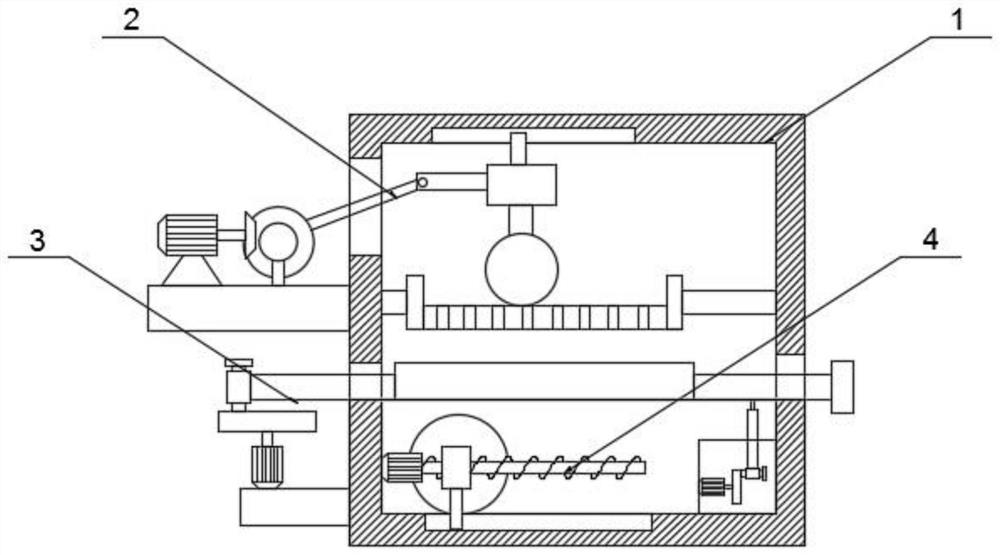

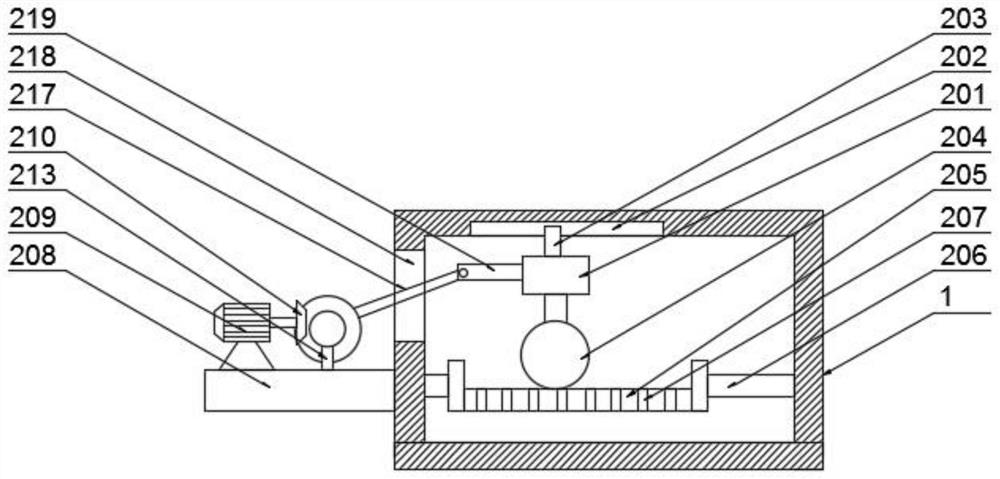

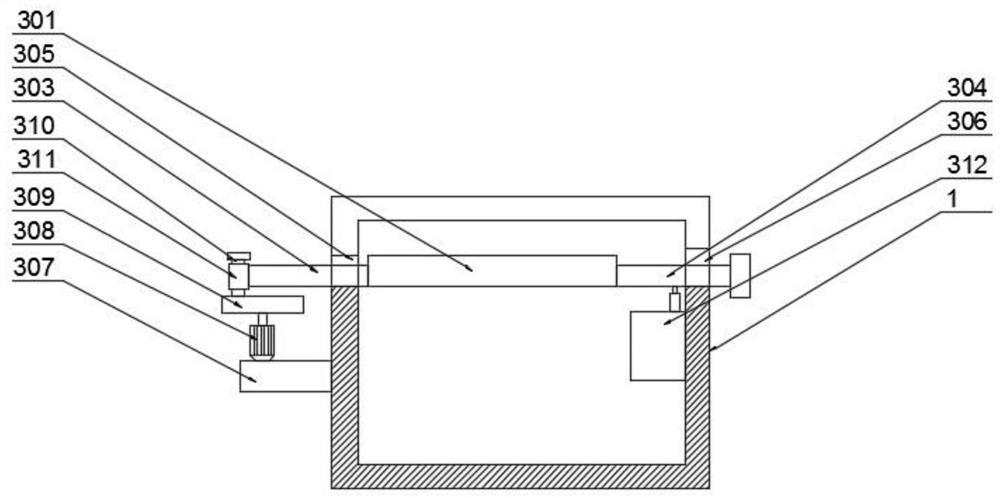

Image

Examples

Embodiment 1

[0052] Super retarded concrete, comprising the following raw materials in parts by weight: 20 parts of quartzite, 30 parts of cement, 10 parts of super retarder and 100 parts of water;

[0053] The ultra-retarded concrete is made by the following steps:

[0054] The first step is to clean and dry the quartz rock, and grind the dried quartz rock through a grinding device to obtain quartz stone powder;

[0055] The second step is to mix the quartz stone powder with water and stir evenly to prepare the quartz stone mortar;

[0056] The third step is to mix cement and quartz stone mortar to obtain raw material A;

[0057] The fourth step is to stir the raw material A with a mixer, add water and a super retarder to prepare super retarded concrete.

[0058] The super retarder is made of the following raw materials in parts by weight: 15 parts of ethylenediaminetetramethylene phosphoric acid, 10 parts of aminotrimethylene phosphoric acid, 15 parts of hydroxymethylpropyl cellulose, ...

Embodiment 2

[0061] Super retarded concrete, comprising the following raw materials in parts by weight: 25 parts of quartzite, 40 parts of cement, 13 parts of super retarder and 120 parts of water;

[0062] The ultra-retarded concrete is made by the following steps:

[0063] The first step is to clean and dry the quartz rock, and grind the dried quartz rock through a grinding device to obtain quartz stone powder;

[0064] The second step is to mix the quartz stone powder with water and stir evenly to prepare the quartz stone mortar;

[0065] The third step is to mix cement and quartz stone mortar to obtain raw material A;

[0066] The fourth step is to stir the raw material A with a mixer, add water and a super retarder to prepare super retarded concrete.

[0067] The super retarder is made of the following raw materials in parts by weight: 17 parts of ethylenediamine tetramethylene phosphoric acid, 17 parts of amino trimethylene phosphoric acid, 17 parts of hydroxymethyl propyl cellulos...

Embodiment 3

[0070] Super retarded concrete, comprising the following raw materials in parts by weight: 30 parts of quartzite, 50 parts of cement, 15 parts of super retarder and 150 parts of water;

[0071] The ultra-retarded concrete is made by the following steps:

[0072] The first step is to clean and dry the quartz rock, and grind the dried quartz rock through a grinding device to obtain quartz stone powder;

[0073] The second step is to mix the quartz stone powder with water and stir evenly to prepare the quartz stone mortar;

[0074] The third step is to mix cement and quartz stone mortar to obtain raw material A;

[0075] The fourth step is to stir the raw material A with a mixer, add water and a super retarder to prepare super retarded concrete.

[0076] The super retarder is made of the following raw materials in parts by weight: 20 parts of ethylenediamine tetramethylene phosphoric acid, 15 parts of aminotrimethylene phosphoric acid, 20 parts of hydroxymethyl propyl cellulose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com