Wood stick punching equipment for furniture production

A kind of punching equipment and wooden stick technology, which is applied in the direction of fixed drilling machines, etc., can solve the problems of uneven punching of wooden sticks, hot sawdust, and people's injuries, so as to avoid burnt sawdust, improve quality and safety, and fast fix Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

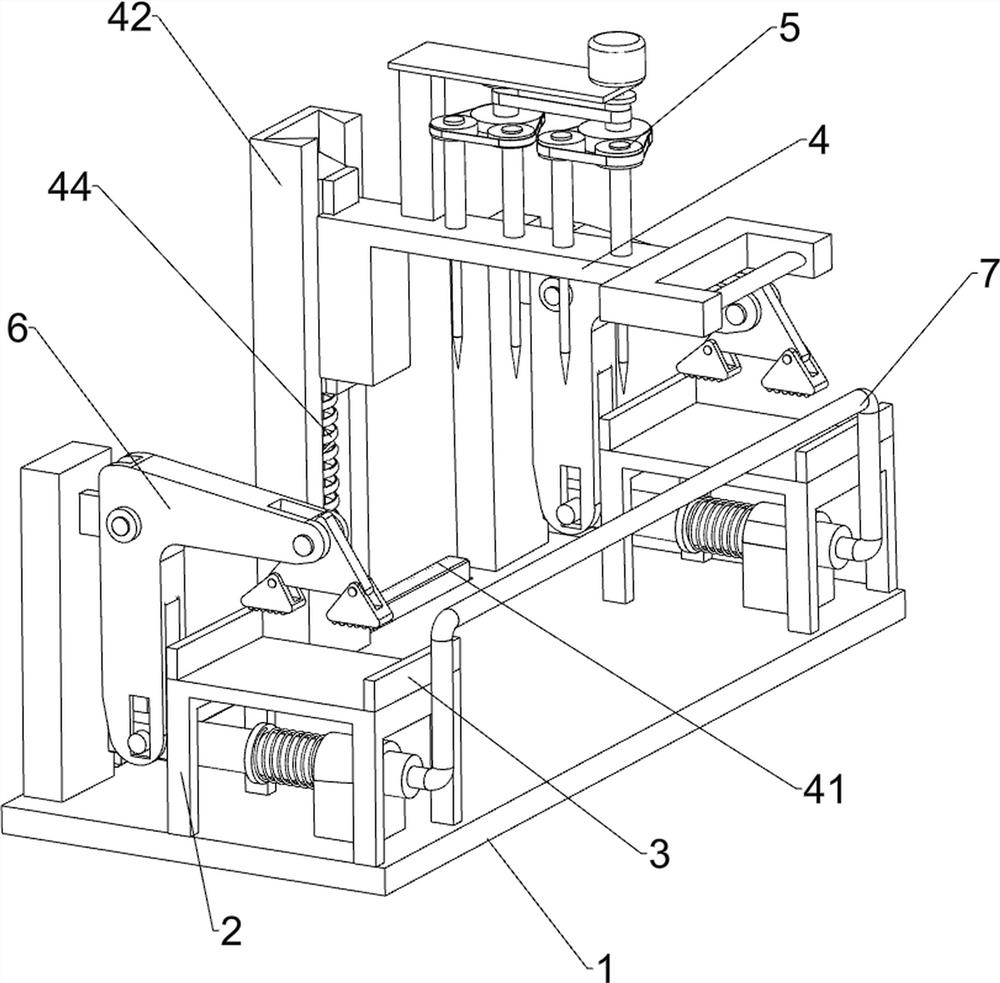

[0021] A wooden stick punching equipment for furniture production, such as figure 1 and figure 2 As shown, it includes a base plate 1, a placement frame 2, a baffle plate 3, a sliding mechanism 4 and a punching mechanism 5, the front and rear sides of the top of the base plate 1 are connected with the placement frame 2, and the left and right sides of the top of the placement frame 2 are connected with The left side of the baffle plate 3 and the top of the bottom plate 1 is slidably connected with a sliding mechanism 4 , and the right side of the upper part of the sliding mechanism 4 is connected with a punching mechanism 5 .

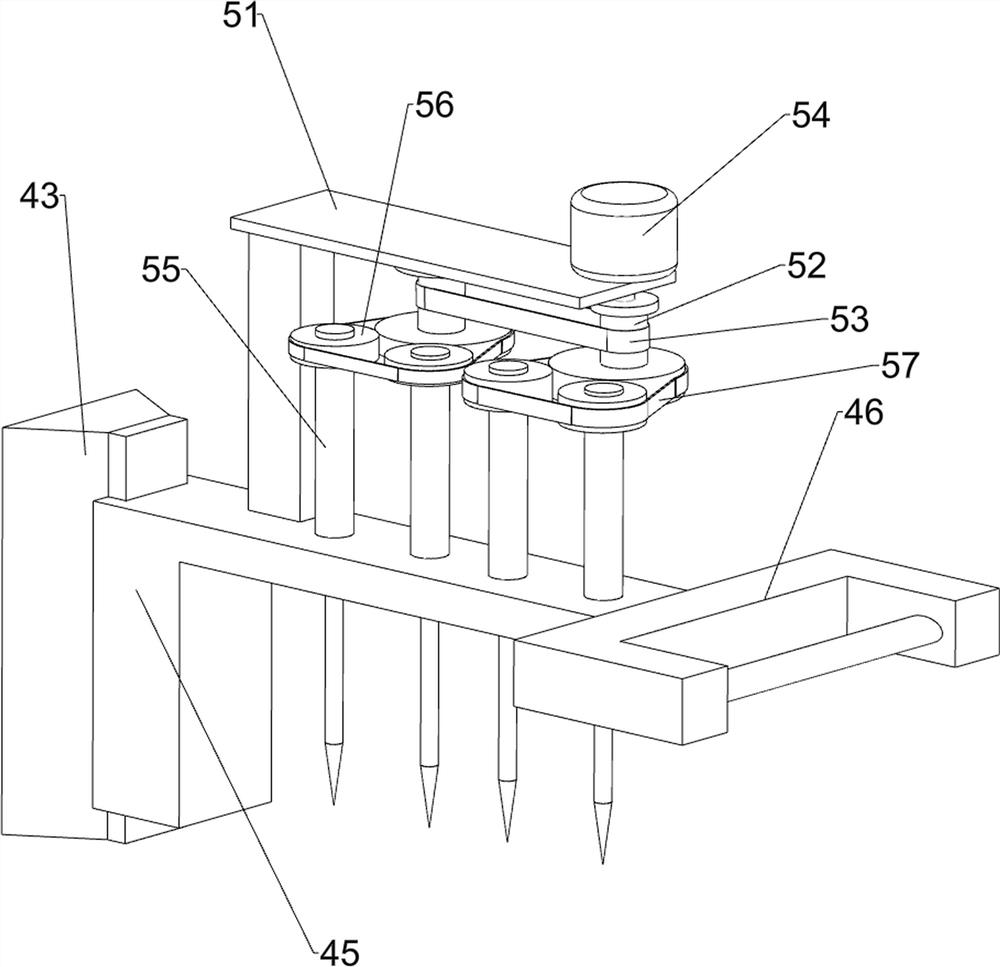

[0022] Sliding mechanism 4 comprises horizontal slide rail 41, vertical slide rail 42, slide block 43, support spring 44, first mounting bracket 45 and handle 46, and the left side of bottom plate 1 top is connected with horizontal slide rail 41, and the left side of horizontal slide rail 41 The upper part is slidably connected with a vertical slide r...

Embodiment 2

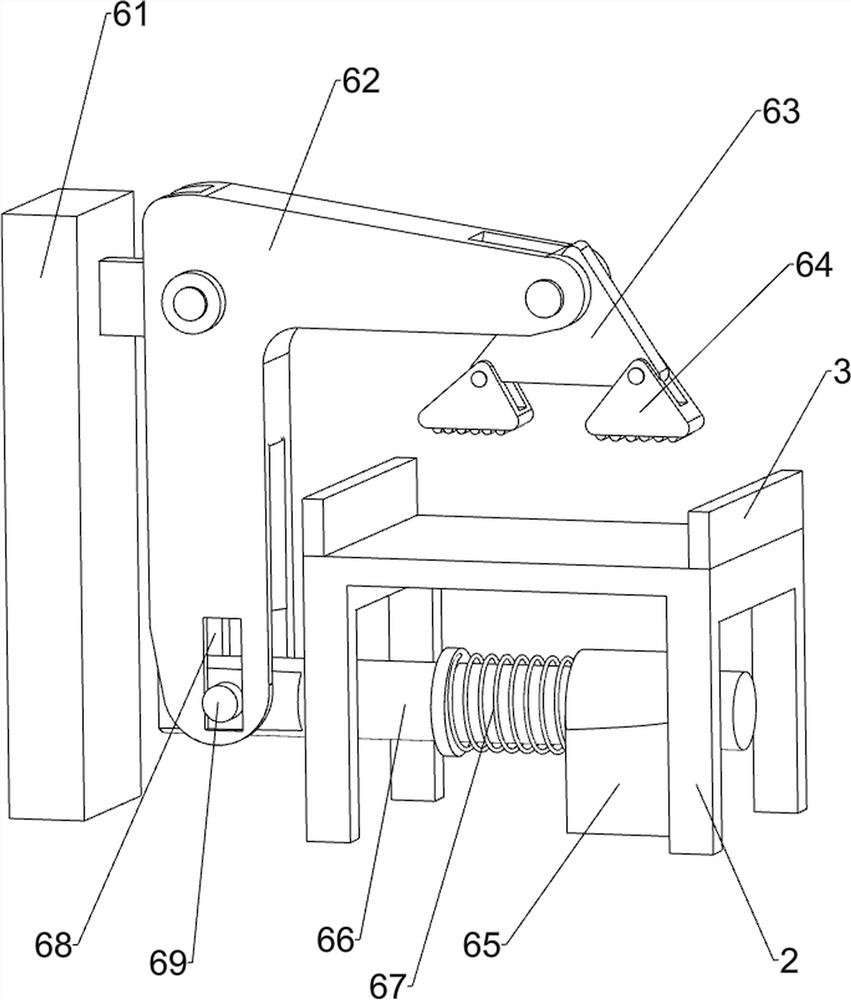

[0026] On the basis of Example 1, such as figure 1 and image 3 As shown, a clamping mechanism 6 is also included, and the clamping mechanism 6 includes a support column 61, an L-shaped swing arm 62, a clamping arm 63, a clamping block 64, a guide sleeve 65, a slide bar 66, a compression spring 67 and Positioning columns 69, the front and rear ends of the top left side of the base plate 1 are connected with supporting columns 61, the front sides of the two supporting columns 61 tops are hingedly connected with L-shaped swing arms 62, and the front sides of the two L-shaped swing arms 62 are connected to each other. Clamping arms 63 are hingedly connected, the bottoms of the two L-shaped swing arms 62 are provided with through grooves 68, the left and right sides of the clamping arms 63 bottoms are hingedly connected with clamping blocks 64, and the front and rear sides on the right side of the top of the base plate 1 Both ends are connected with guide sleeves 65, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com