Hybrid drive system and vehicle

A drive system and hybrid technology, applied in hybrid vehicles, motor vehicles, power units, etc., can solve the problems of large size and high cost, and achieve the effects of improving driving stability, facilitating speed regulation, and improving fuel economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

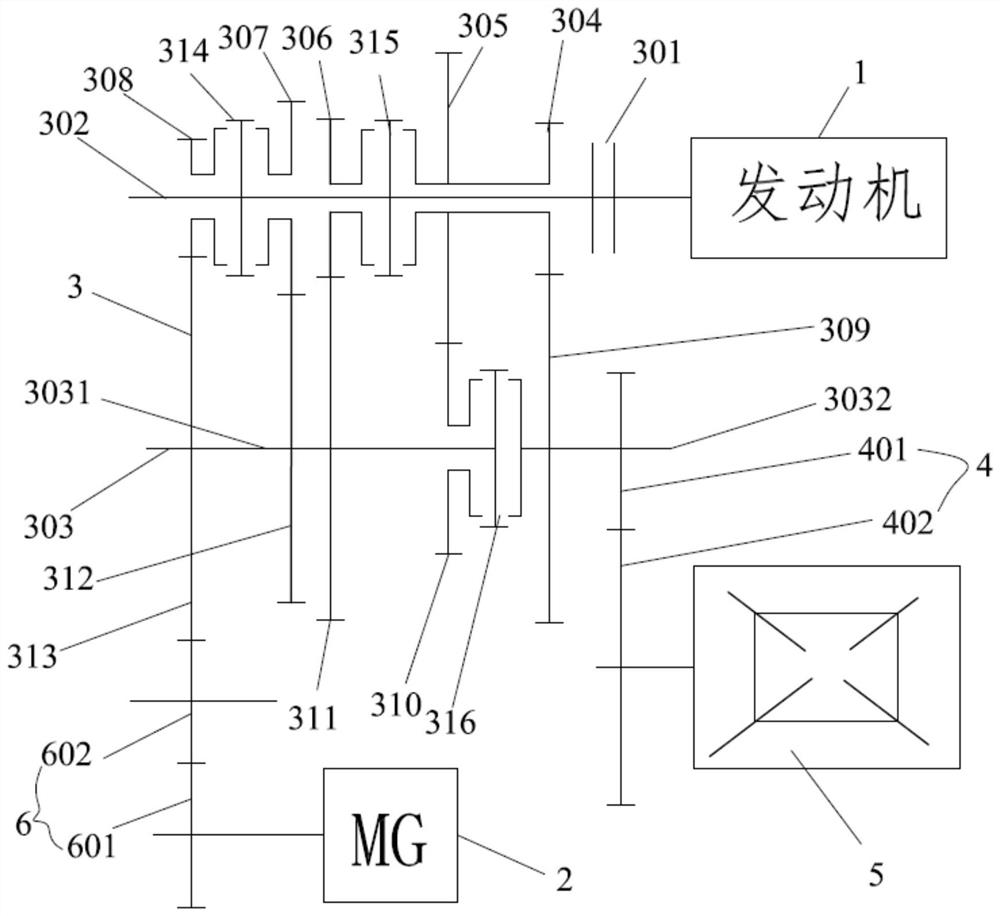

[0081] Such as figure 1 As shown, the hybrid drive system 100 provided by the first embodiment of the present application includes an engine 1 , a gearbox and a motor 2 , and the gearbox includes a speed change mechanism 3 and a final reducer 4 .

[0082] The speed change mechanism 3 includes a clutch device 301, an input shaft 302, an output shaft 303, a synchronizing device, a plurality of driving gears arranged on the input shaft 302 and a plurality of driving gears arranged on the output shaft 303 and a plurality of the driving gears arranged on the output shaft 303. The gears correspond to a plurality of driven gears, and the clutch device 301 is connected between the engine 1 and the input shaft 302 . The motor 2 is connected to the output shaft 303 through a reduction gear set 6, and the output shaft 303 is connected to the final reducer 4 to output power.

[0083] The output shaft 303 is disconnected in the middle into a first output shaft 3031 and a second output sha...

no. 2 example

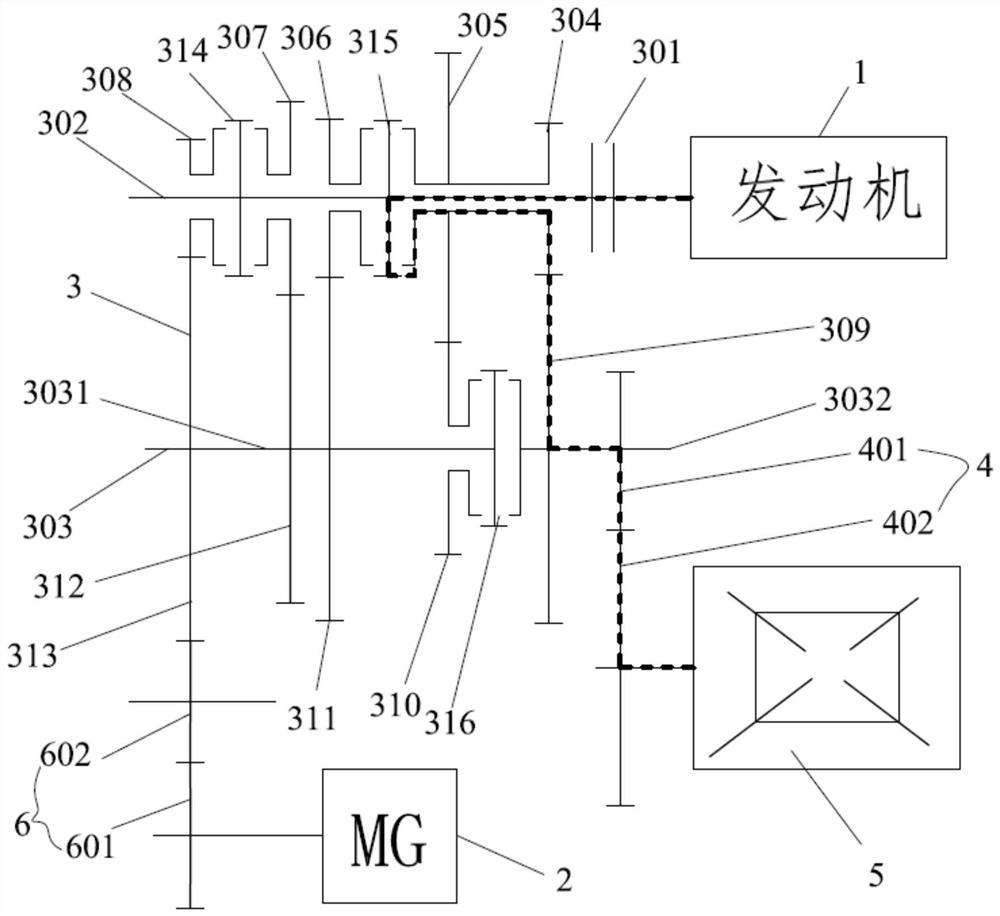

[0119] Figure 22 A hybrid drive system 100 of a second embodiment of the present application is shown. It differs from the first embodiment as follows:

[0120] In the second embodiment, the plurality of driving gears include a first driving gear 304 , a second driving gear 305 , a third driving gear 306 , The fourth driving gear 307 and the fifth driving gear 308; the plurality of driven gears include a first driven gear 309, a second driven gear 310, a third driven gear arranged in sequence in a direction away from the engine 1 Gear 311, the fourth driven gear 312 and the fifth driven gear 313, the first driven gear 309 and the second driven gear 310 are fixed on the second output shaft 3032, the third driven gear 311 is loosely sleeved on the first output shaft 3031 , and the fourth driven gear 312 and the fifth driven gear 313 are fixed on the first output shaft 3031 . The first driving gear 304 meshes with the first driven gear 309, the second driving gear 305 meshes ...

no. 3 example

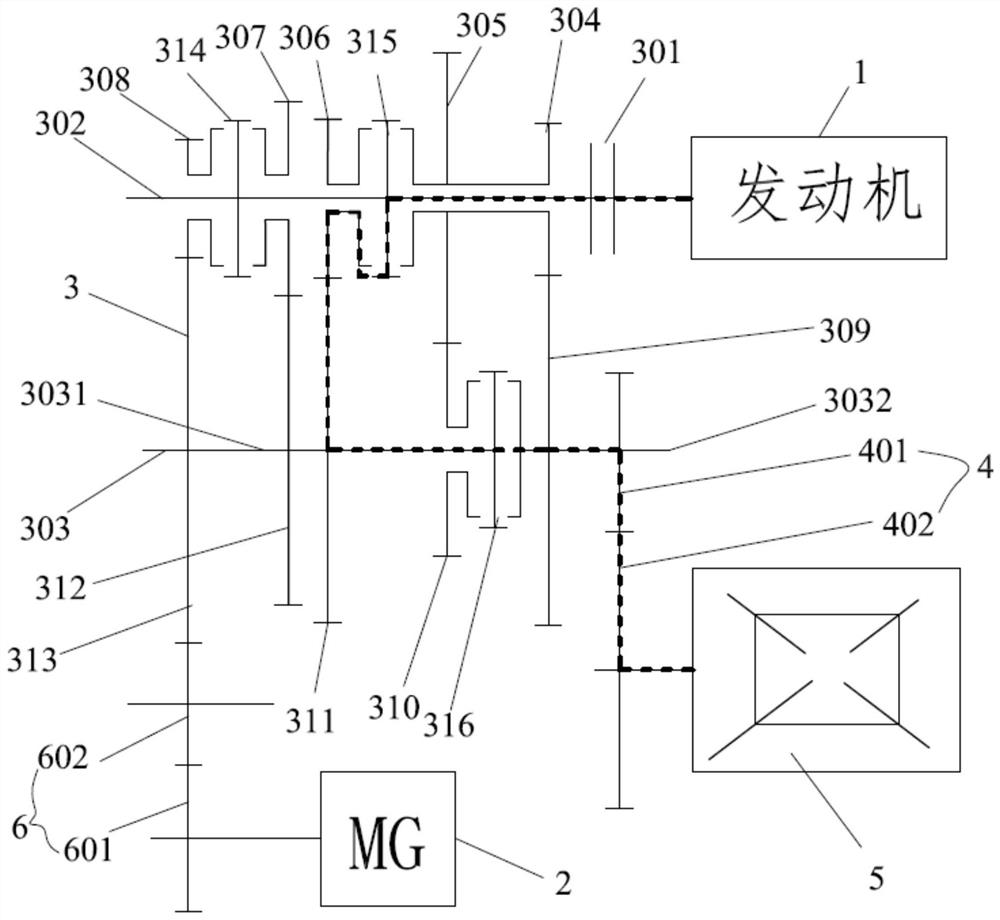

[0124] Figure 23 A hybrid drive system 100 of a third embodiment of the present application is shown. It differs from the first embodiment as follows:

[0125] The motor 2 is connected to the input shaft 302 through the reduction gear set 6 . The intermediate gear 602 meshes with the fifth driving gear 308 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com