Step-by-step unmanned loading system

A step-by-step, vehicle technology, applied in transportation and packaging, loading/unloading, etc., can solve problems such as low loading efficiency, and achieve the effect of improving loading efficiency and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

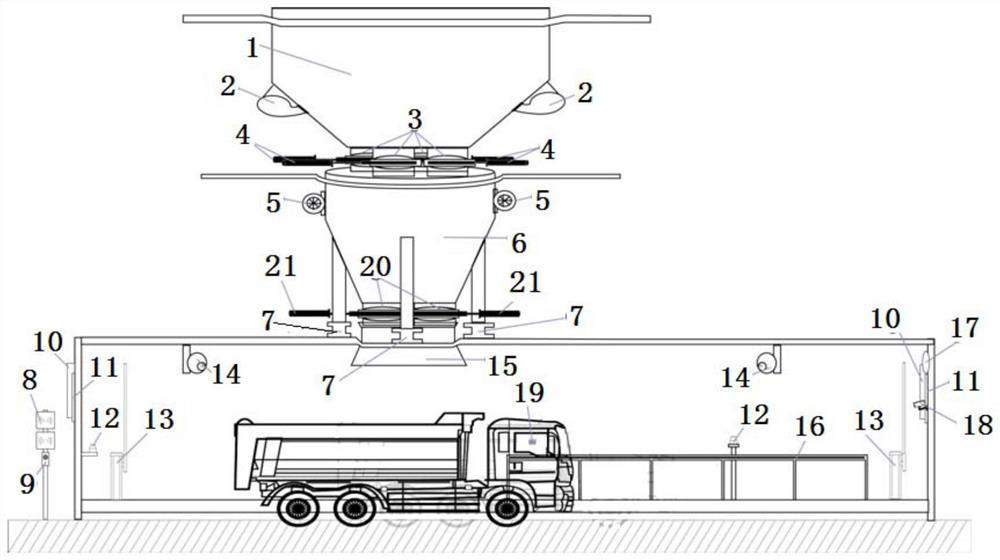

[0042] Such as figure 1 Shown is a step-by-step unmanned loading system disclosed by the present invention, including:

[0043] The vehicle information identification module 8 is arranged at the entrance of the material loading area to identify the incoming vehicles and send the identified vehicle information to the data processing module;

[0044] The hopper loading system is arranged on the top of the material loading area for loading the vehicle driving to the bottom of the distributor of the hopper loading system and sends a loading completion signal to the data processing module after the loading is completed;

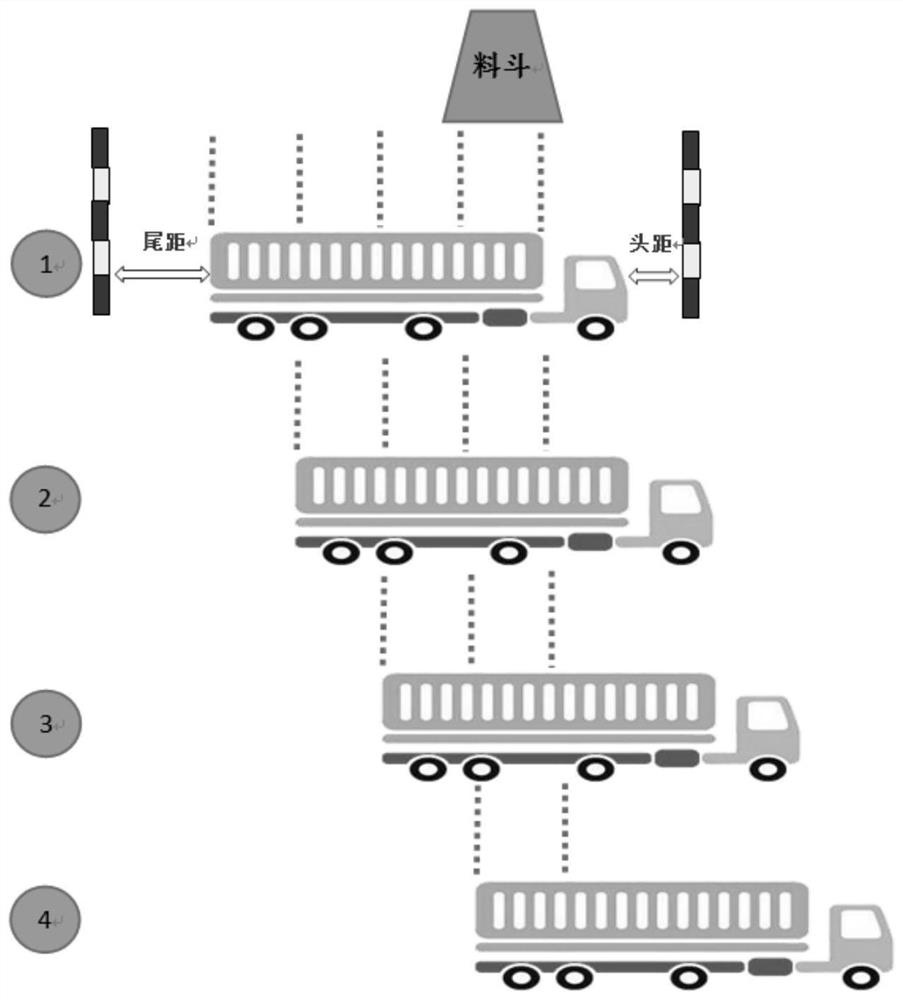

[0045] The distance measuring module includes a rotating laser range finder 12 arranged on the side of the front end and / or rear end of the material loading area, and the rotating laser range finder is used to scan the material loading area to obtain the front or rear of the vehicle and the The distance information of the rotating laser rangefinder and sending th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com