Marine diesel engine frequency modulation wheel lifting tool and lifting method

A marine diesel engine and frequency modulation wheel technology, applied in the direction of transportation and packaging, load suspension components, etc., can solve the problems of increasing the difficulty of installation workers, uneven force on frequency modulation wheels, and increased safety hazards, etc., to solve the problem of assembly and The lifting problem of replacement, the effect of reducing installation cost and reducing installation man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

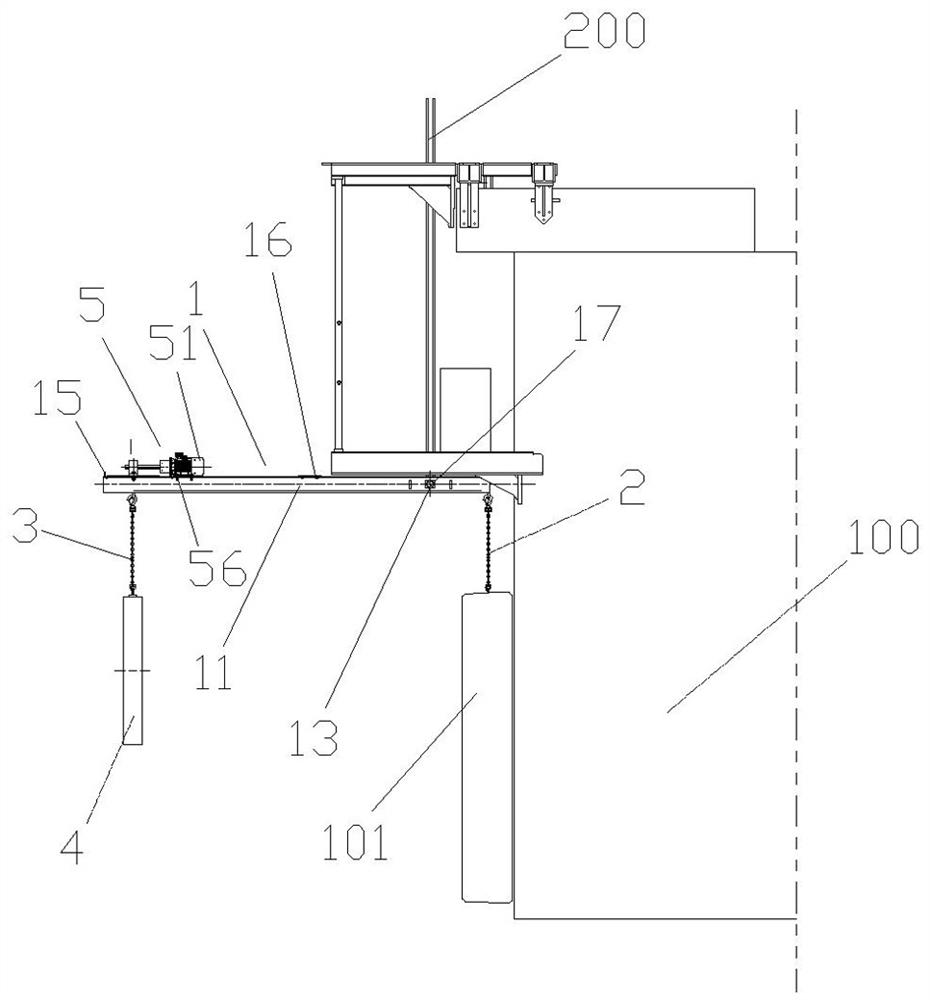

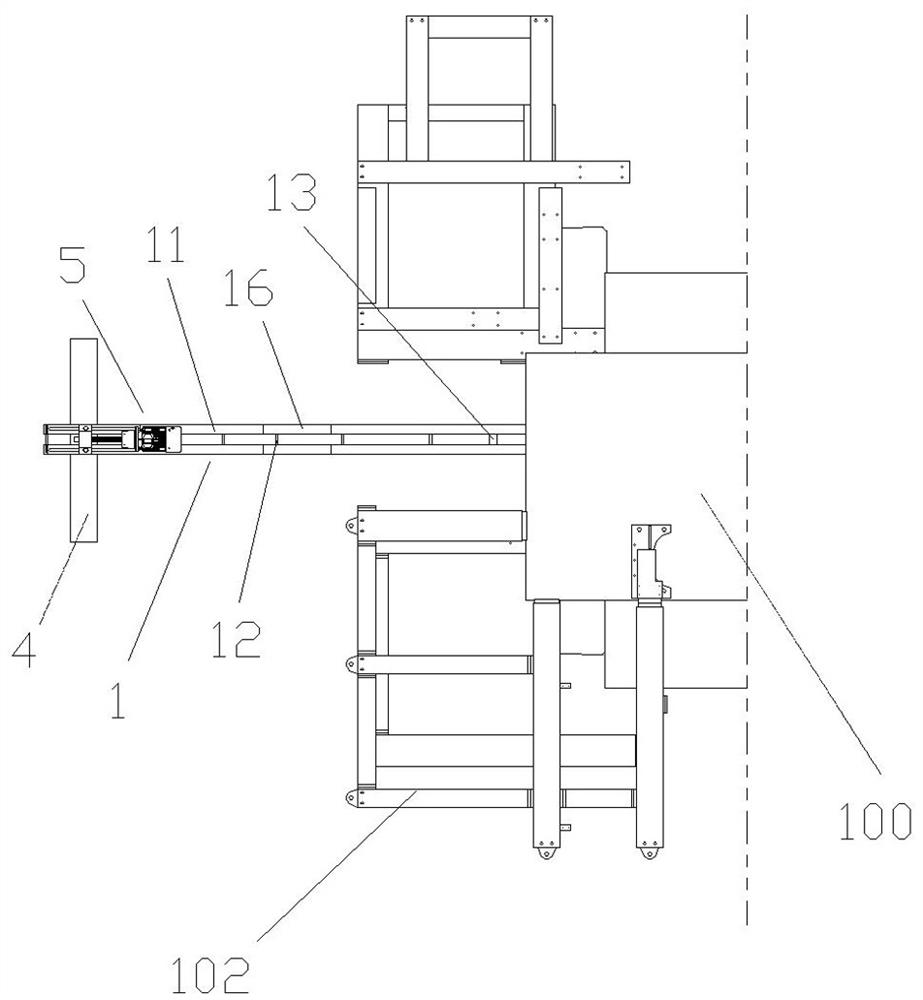

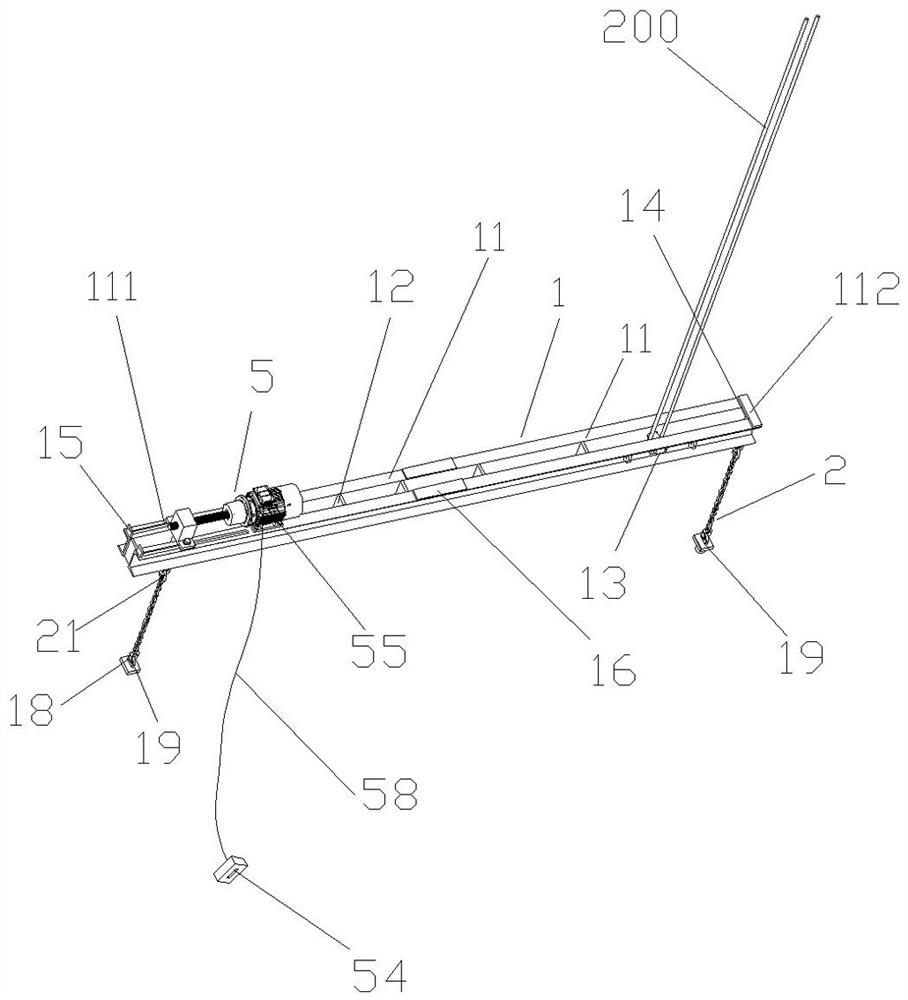

[0022] The present invention will be further described below in conjunction with the accompanying drawings and the embodiment of the hoisting tooling and hoisting method for hoisting the S40MEB9.5 type marine diesel engine frequency modulation wheel. The quality of the tuning wheel 101 of this embodiment is 6500kg.

[0023] Such as Figure 1 ~ Figure 3 As shown, this embodiment includes a crossbeam 1, a frequency modulation wheel suspension chain 2, a counterweight suspension chain 3, a counterweight 4 and a counterweight position adjustment device 5, and the crossbeam 1 is a welded part of section steel, including two channel steels 11, 5 cross braces 12, hoisting cross pins 13 and frequency modulation wheel hanging plates 14, the backs of two channel steels 11 are arranged parallel to each other, 4 cross braces 12 are welded and fixed between the two channel steels 11 at intervals, and the frequency modulation wheel suspensions are 14 is vertically welded and fixed on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com