Multistage micro-power self-reflux sewage treatment reactor

A sewage treatment and reactor technology, applied in the field of water treatment, can solve the problems of large floor area, increased power consumption, high construction investment, etc., achieve floor space saving, efficient denitrification and phosphorus removal, reduce construction cost and The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

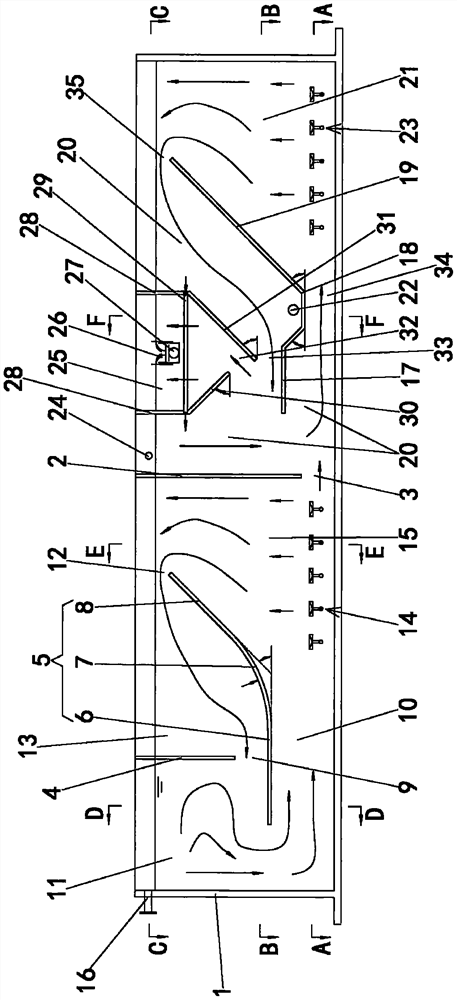

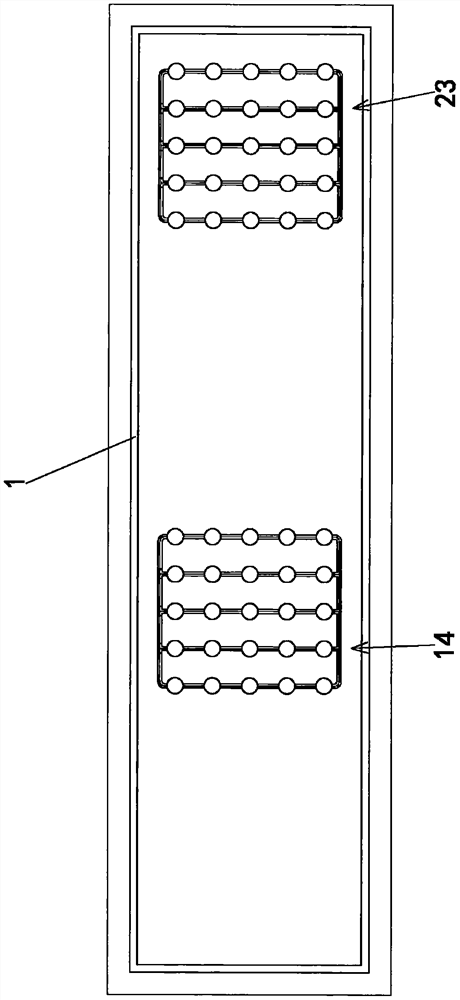

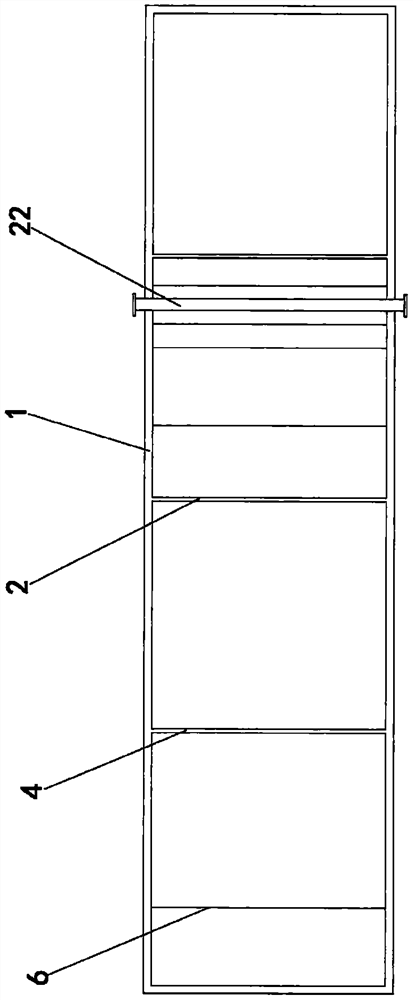

[0033] Such as Figure 1 to Figure 7As shown, the microdynamic self-reflux sewage treatment reactor of the present invention includes a hollow reactor body 1, and the reactor body 1 of this embodiment is in the shape of a cuboid. The reactor body 1 divides the inner cavity into two parts, the primary reaction zone and the secondary reaction zone, through the partition plate 2 arranged on the upper wall of the interior cavity. The partition plate 2 of this embodiment is vertically connected to the interior of the reactor body 1 chamber wall. A first water passage 3 is formed between the lower end of the partition plate 2 and the reactor body 1 . The primary reaction zone is provided with a primary hydraulic circulation structure, and the secondary reaction zone is provided with a secondary hydraulic circulation structure.

[0034] The primary hydraulic circulation structure includes a first deflector 4 vertically arranged on the upper wall of the primary reaction zone and a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com