A kind of PVC sole injection molding polyurethane surface layer resin and preparation method

A technology of surface layer resin and polyurethane, which is applied in the field of polyurethane surface layer resin for injection molding of PVC soles and its preparation, can solve the problems of many production processes, easy separation, and insufficient peel strength, and achieve the effect of not being easy to degumming and improving the bonding strength

Active Publication Date: 2022-06-03

ZHEJIANG HUAFON SYNTHETIC RESIN

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This traditional production method not only leads to very high production costs due to many production processes, but also pollutes the environment because of the use of a large amount of adhesives, which does not meet the requirements of modern production for environmental protection. It is made of glue, the use time is short, and it is easier to open the glue

In order to solve the defects in the existing technology, modern enterprises have invented a production method of one-time injection molding of the shoe upper and the sole, which has relatively high requirements for the shoe leather surface. If the injection molding effect is not good - the shoe upper, The peeling strength of the sole through heat lamination is not enough, it is extremely easy to separate, which affects the quality of the finished product, and the yield of injection molding is low

Injection-type dry-process surface layer polyurethane resin products are required to be suitable for the preparation of synthetic leather surface layers that are directly attached to the soles of injection molding processes, and to change the defects of using glue in the past, high production costs, and not being environmentally friendly. The key lies in not using glue. Under the condition of mixture, improve the bonding strength between the surface layer made of injection-molded dry-process polyurethane resin products and the sole formed by injection molding process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

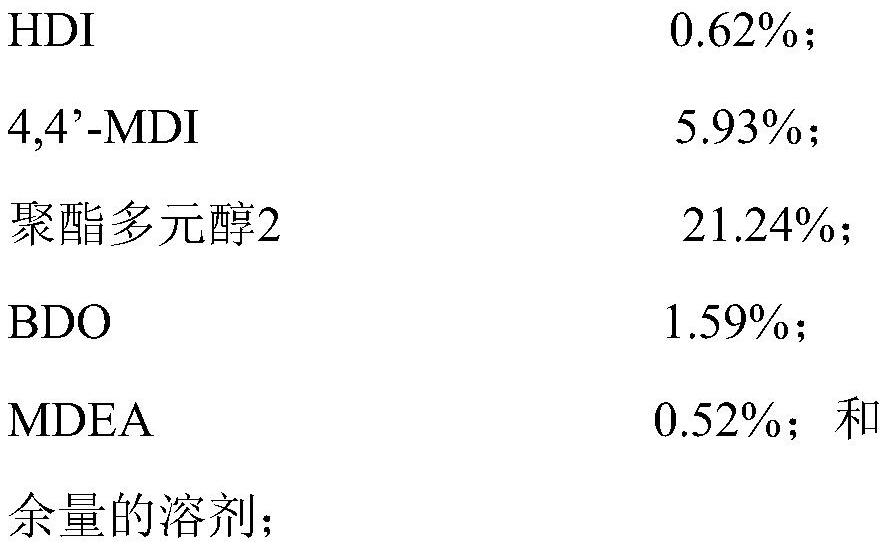

[0044]

[0050] Methanol is added in the later stage of step B, and the addition amount is 0.05% of the total resin mass.

Embodiment 2

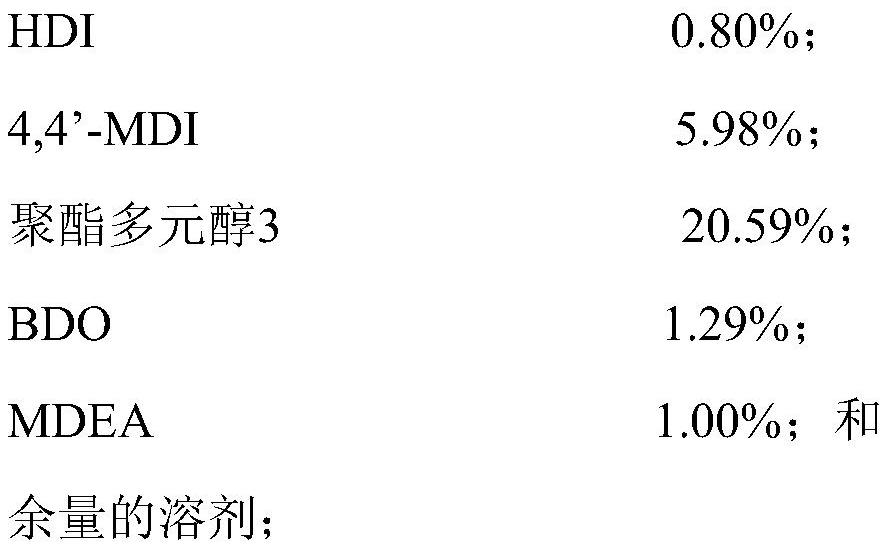

[0053]

[0059] Methanol is added in the later stage of step B, and the addition amount is 0.05% of the total resin mass.

Embodiment 3

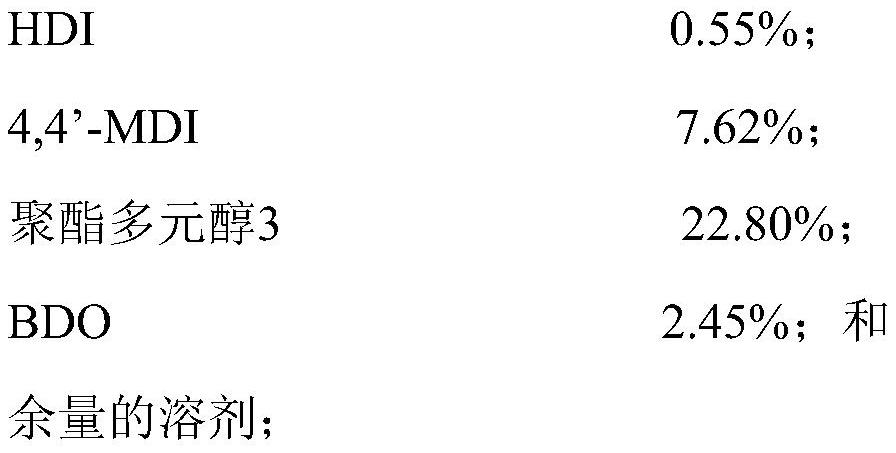

[0062]

[0068] Methanol is added in the later stage of step B, and the addition amount is 0.05% of the total resin mass.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a polyurethane surface layer resin for injection molding of PVC shoe soles and a preparation method thereof. The surface layer resin is composed of the following components in weight percent: 5% to 12% of diisocyanate; 18% to 25% of polyester polyol; 0.5% to 1.5% of chain extender; and the remaining solvent; the preparation method is as follows: step A: adding polyester polyol and solvent accounting for 25% to 40% of the total weight of the components into the reaction vessel, at 50 to 60 After stirring for 20-30 minutes at ℃, add aliphatic diisocyanate, heat up to 100-110℃ and continue to stir for 100-120 minutes; step B: add the remaining solvent and chain extender and stir for 30 minutes, then add aromatic diisocyanate, The temperature is controlled at 70-80°C, the viscosity of the reactant is controlled at 100-160 Pa.s / 25°C, and the temperature is lowered to obtain the polyurethane surface layer resin for injection molding of PVC shoe soles. Without the use of adhesives, it can greatly improve the bonding strength between the surface layer made of injection-molded dry-process polyurethane resin products and the sole formed by injection molding.

Description

A kind of polyurethane surface layer resin for injection molding of PVC shoe sole and preparation method thereof technical field The present invention relates to a kind of polyurethane surface layer resin for injection molding of PVC sole and preparation method. Background technique [0002] Polyurethane resin, as the main raw material of synthetic leather, plays a decisive role in the performance of synthetic leather. Currently, In traditional shoes, the upper and the sole are formed separately, and then the upper and the sole are bonded together with adhesives. The bond is stronger, and may eventually need to be stitched or further fixed with nails, which requires multiple work procedures, such as: gluing, pressing, sewing and other processes. This traditional production method not only leads to production costs due to many production processes It is very high, and because a large amount of adhesive is used, it also brings pollution to the environment, which does n...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08G18/76C08G18/73C08G18/72C08G18/66C08G18/42C08G18/32A43B13/04

CPCC08G18/7671C08G18/73C08G18/724C08G18/664C08G18/4607C08G18/3206A43B13/04Y02P70/62

Inventor 杜飘扬张初银吴震林上河王江海木国亭

Owner ZHEJIANG HUAFON SYNTHETIC RESIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com