Polyurethane surface layer resin for PVC sole injection molding and preparation method thereof

A technology of surface layer resin and polyurethane, which is applied in the field of polyurethane surface layer resin for PVC shoe sole injection molding and its preparation, can solve the problems of easy separation, many production processes, and insufficient peel strength, and achieve the effect of improving bonding strength and not easy to degumming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

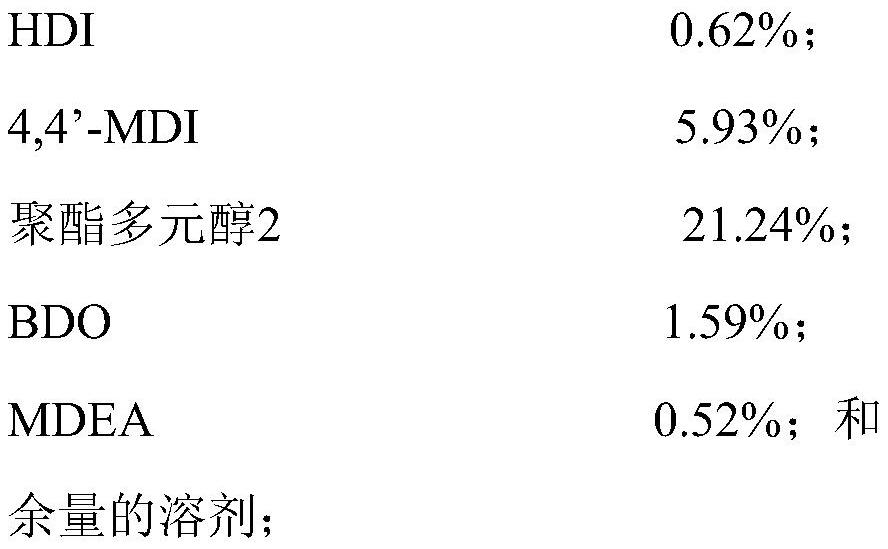

[0043] Polyurethane surface layer resin The polyurethane surface layer resin consists of the following components in weight percentage:

[0044]

[0045] The preparation of polyurethane surface layer resin is obtained through the following steps:

[0046] Step A: Add polyester polyol 2 and 32.15% solvent into the reaction vessel, stir at 50°C for 30 minutes, add HDI, heat up to 100°C and continue stirring for 100 minutes;

[0047] The isocyanate index of the reactant in the step A is 0.70:1;

[0048] Step B: Add the remaining 37.95% solvent and chain extender and stir for 30 minutes, add 4,4'-MDI, control the temperature at 75°C, control the viscosity of the reactant to 150Pa.s / 25°C, and cool down to obtain polyurethane for injection molding of PVC soles Surface resin;

[0049] The catalyst BICAT 8108 is added in the step A, and the addition amount is 0.01% of the total mass of the resin;

[0050] Add methanol at the later stage of step B, and the added amount is 0.05% o...

Embodiment 2

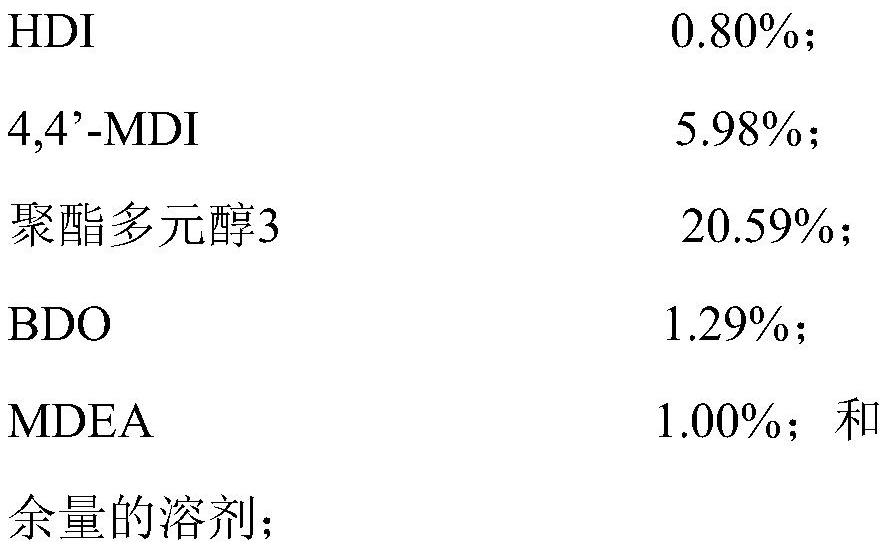

[0052] The polyurethane surface layer resin is composed of the following components in weight percentage:

[0053]

[0054] The preparation of polyurethane surface layer resin is obtained through the following steps:

[0055] Step A: Add polyester polyol 3 and 32.62% solvent into the reaction vessel, stir at 55°C for 30 minutes, add HDI, heat up to 110°C and continue stirring for 100 minutes;

[0056] The isocyanate index of the reactant in the step A is 0.80:1;

[0057] Step B: Add the remaining 37.73% solvent and chain extender and stir for 30 minutes, add 4,4'-MDI, control the temperature at 70°C, control the viscosity of the reactant to 140Pa.s / 25°C, and cool down to obtain polyurethane for injection molding of PVC soles Surface resin;

[0058]The catalyst BICAT 8108 is added in the step A, and the addition amount is 0.01% of the total mass of the resin;

[0059] Add methanol at the later stage of step B, and the added amount is 0.05% of the total mass of the resin. ...

Embodiment 3

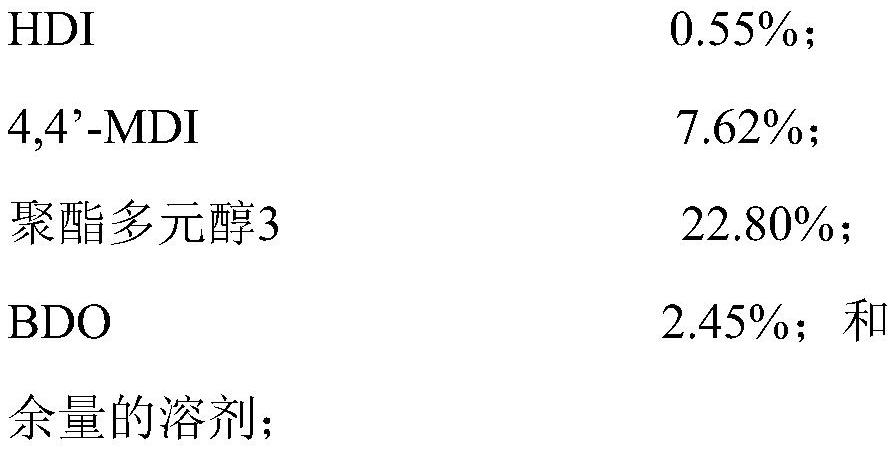

[0061] The polyurethane surface layer resin is composed of the following components in weight percentage:

[0062]

[0063] The preparation of polyurethane surface layer resin is obtained through the following steps:

[0064] Step A: Add polyester polyol 3 and 30.21% solvent into the reaction vessel, stir at 60°C for 20 minutes, add HDI, heat up to 100°C and continue stirring for 120 minutes;

[0065] The isocyanate index of the reactant in the step A is 0.50:1;

[0066] Step B: Add the remaining 36.37% solvent and chain extender and stir for 30 minutes, add 4,4'-MDI, control the temperature at 80°C, control the viscosity of the reactant to 142Pa.s / 25°C, and cool down to obtain polyurethane for injection molding of PVC soles Surface resin;

[0067] The catalyst BICAT 8108 is added in the step A, and the addition amount is 0.01% of the total mass of the resin;

[0068] Add methanol at the later stage of step B, and the added amount is 0.05% of the total mass of the resin....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com