Method for obtaining same structure as lead bath quenching process

A technology of lead bath quenching and process, applied in the direction of quenching agent, manufacturing tools, furnace types, etc., can solve the problems of lead pollution environment, human body toxicity, harm to human health, etc., and achieve good section shrinkage rate and hardness performance, tensile strength good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

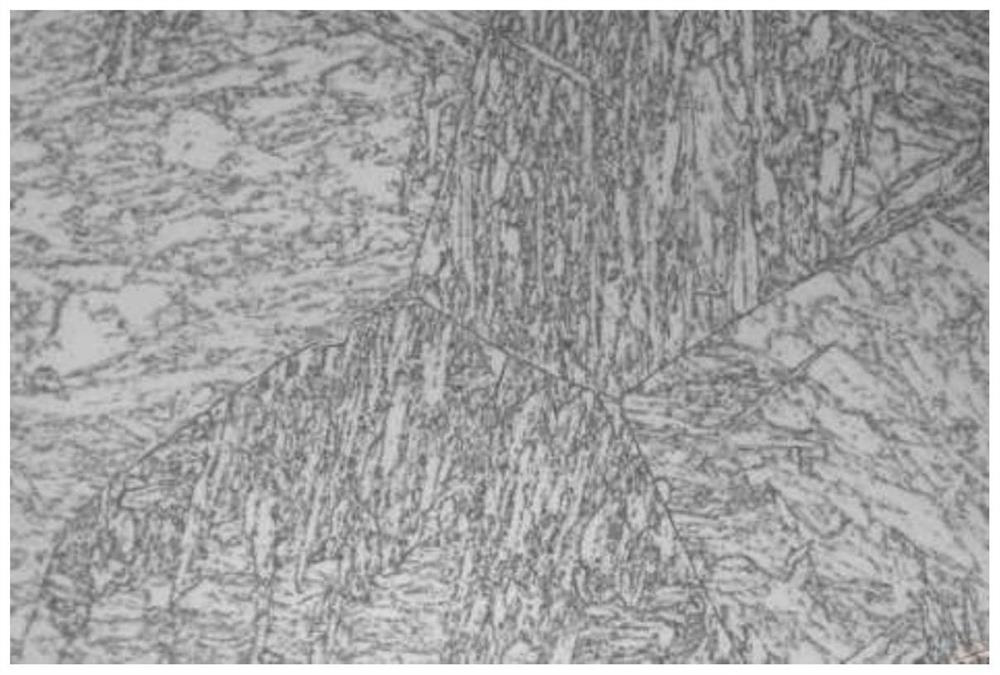

Image

Examples

Embodiment 1

[0019] (1) Quenching the rolled product at 870°C for 30 minutes at a heating rate of 15°C / s; then cooling to 450°C for tempering for 1 hour at a cooling rate of 5°C / s;

[0020] (2) immerse the hot water obtained in step (1) at a temperature of 90-100° C. for quenching, and keep it warm for 2-3 hours;

[0021] (3) Tempering the product obtained in step (2) at 200° C. for 2 hours, and keeping it warm for 1 hour; the obtained metallographic structure is a sorbite structure.

Embodiment 2

[0023] (1) Quenching the rolled product at 880°C for 20 minutes at a heating rate of 15°C / s; then cooling to 460°C for tempering for 0.6h at a cooling rate of 5°C / s;

[0024] (2) immerse the hot water obtained in step (1) at a temperature of 90-100° C. for quenching, and keep it warm for 2-3 hours;

[0025] (3) Tempering the product obtained in step (2) at 200° C. for 2 hours, and keeping it warm for 0.6 hours; the obtained metallographic structure is a sorbite structure.

Embodiment 3

[0027] (1) Quenching the rolled product at 890°C for 15 minutes at a heating rate of 15°C / s; then cooling to 480°C for 0.8h at a cooling rate of 5°C / s;

[0028] (2) immerse the hot water obtained in step (1) at a temperature of 90-100° C. for quenching, and keep it warm for 2-3 hours;

[0029] (3) Tempering the product obtained in step (2) at 210° C. for 1 h, and keeping it warm for 0.8 h; the obtained metallographic structure is a sorbite structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com