E460-W200 ultrahigh-strength ship plate steel and manufacturing method thereof

A manufacturing method and technology for ship plate steel, which are applied in the direction of temperature control, metal rolling, tension/pressure control, etc., can solve the problems of lower temperature, deterioration of low temperature toughness, decreased mechanical properties of welded joints, etc., and achieve cost reduction and excellent welding. The effect of inhibiting the growth of austenite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

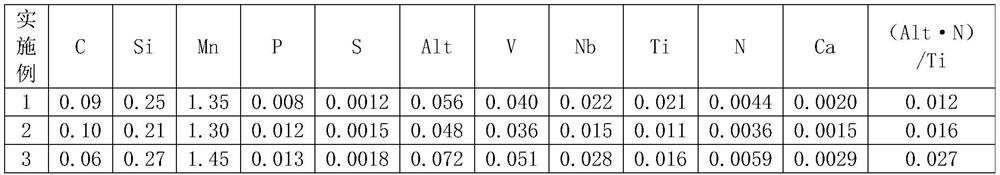

[0026] A kind of E460-W200 ultra-high-strength ship plate steel and its manufacturing method provided in the following examples, the steel plate thickness is 70mm, the chemical composition is shown in Table 1, the rolling cooling process parameters are shown in Table 2, and the product performance is shown in Table 3:

[0027] The main chemical composition (wt%) of the embodiment of table 1

[0028]

[0029] The rolling cooling process parameter of table 2 embodiment

[0030] Example Thickness mm Rough rolling finish temperature ℃ Finish rolling start temperature ℃ Return to red temperature ℃ 1 70 1065 846 510 2 70 1050 820 450 3 70 1081 870 550

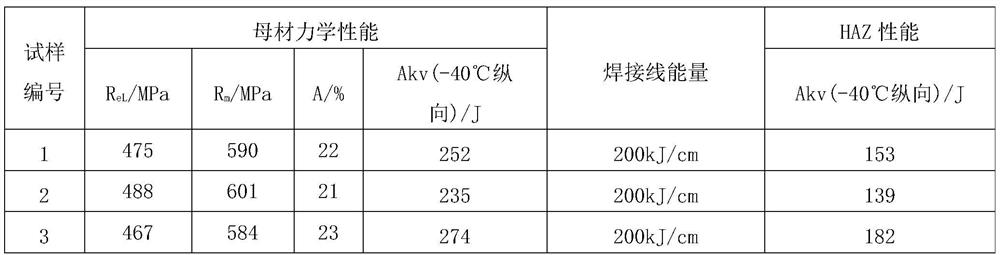

[0031] Table 3 embodiment product performance

[0032]

[0033] It can be seen that the comprehensive mechanical properties of the steel plate obtained by the present invention are good, yield strength ≥ 460MPa, tensile strength ≥ 570MPa, suitable for high-strength ship plate steel wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com