Wall dust scraping device for house construction

A construction and wall technology, which is applied to the field of wall scraping devices for house construction, can solve the problems of difficult scraping operation, easy occurrence of stacking, and small scraping tools, so as to save scraping cycle and improve flatness. , to avoid the effect of stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

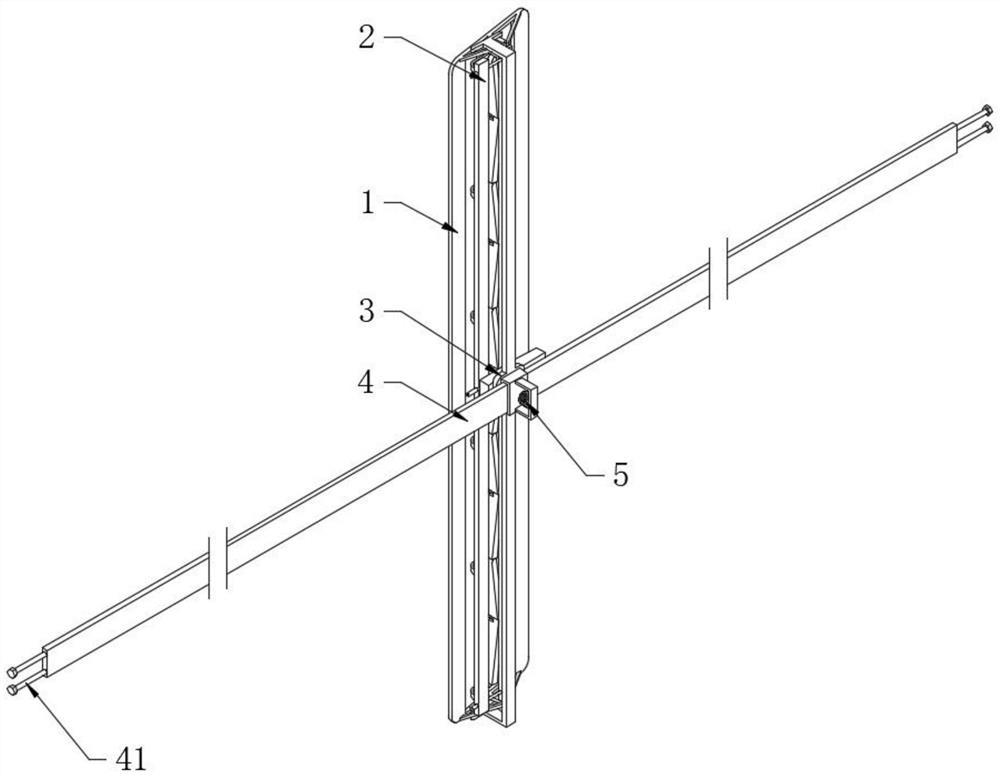

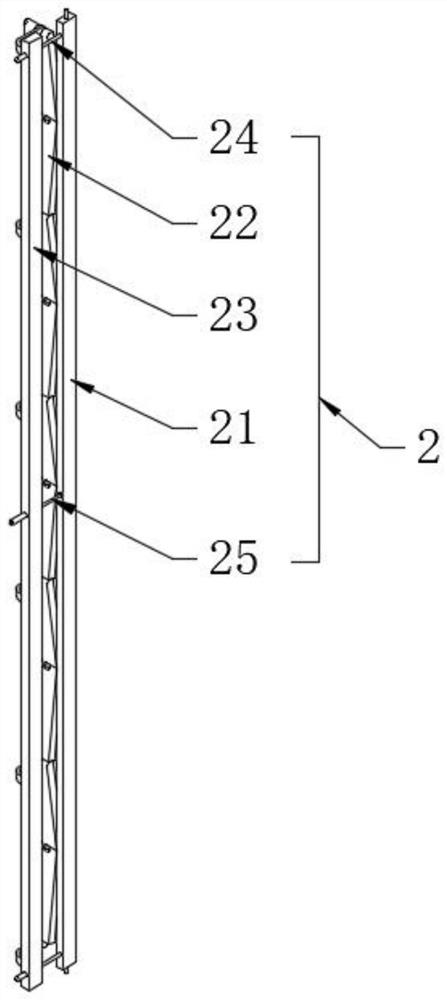

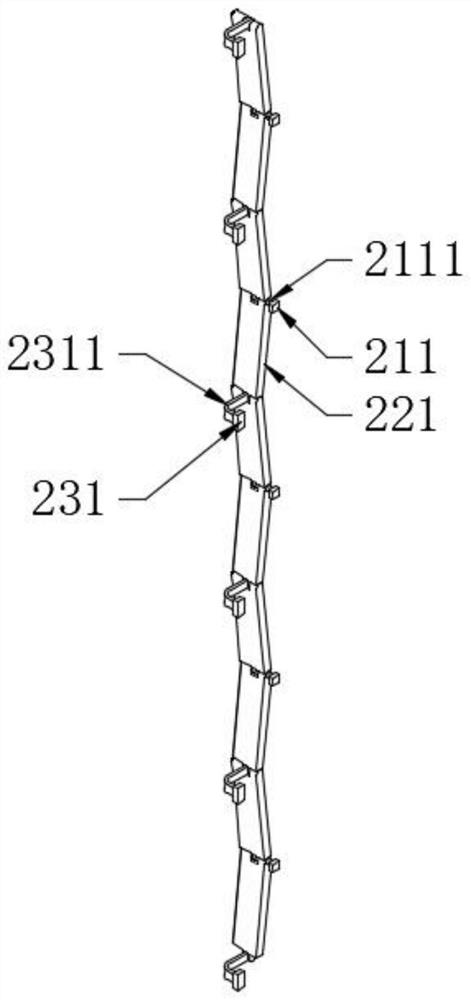

[0032] see Figure 1-5 , A wall ash scraping device for house construction, comprising a ash scraper 1, a wave-type screeding part 2 and a drive frame 3, the function of the wave-type screeding part 2 is to straighten the uneven ash material on the wall surface Dispersion, the ash scraper 1 has the function of leveling the wall ash; the wave type screed part 2 includes a positioning strip plate 21, a wave plate 22, an adjustment strip plate 23, a guide telescopic rod 24 and an elastic cylinder 25. The wave plate 22 is composed of A row of rectangular scrapers 221 is formed, and adjacent rectangular scrapers 221 are hingedly connected, specifically head-to-tail hinged; the positioning strip 21 is provided with a plurality of main sliders 211 distributed along the length direction on the side of the positioning strip 21 near the wall. The sliding block 211 is in sliding fit along the length direction of the positioning strip plate 21. The side of the main sliding block 211 again...

Embodiment 2

[0034] see Figure 4-6, and the difference from Embodiment 1 is that the drive frame 3 is provided with a strip-shaped drive plate 31 that slides with the connection block 212, the connection block 212 is provided with a chute, and the strip-shaped drive plate 31 is provided with a slider that slides with the chute. , the sliding direction is the same as the scraping action direction; the two ends of the strip-shaped driving plate 31 are provided with T-shaped plates 311, and the connecting frame 213 is an isosceles triangle frame structure and is rotatably connected with the strip-shaped driving plate 31. The connecting frame 213 is close to the The two equilateral joints of the isosceles triangle frame are connected to the strip drive plate 31. One side of the T-shaped plate 311 is provided with two drive shafts 3111 that cooperate with the two oblique edges on the connecting frame 213. The number of 1 is two and is symmetrically distributed relative to the connecting frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com