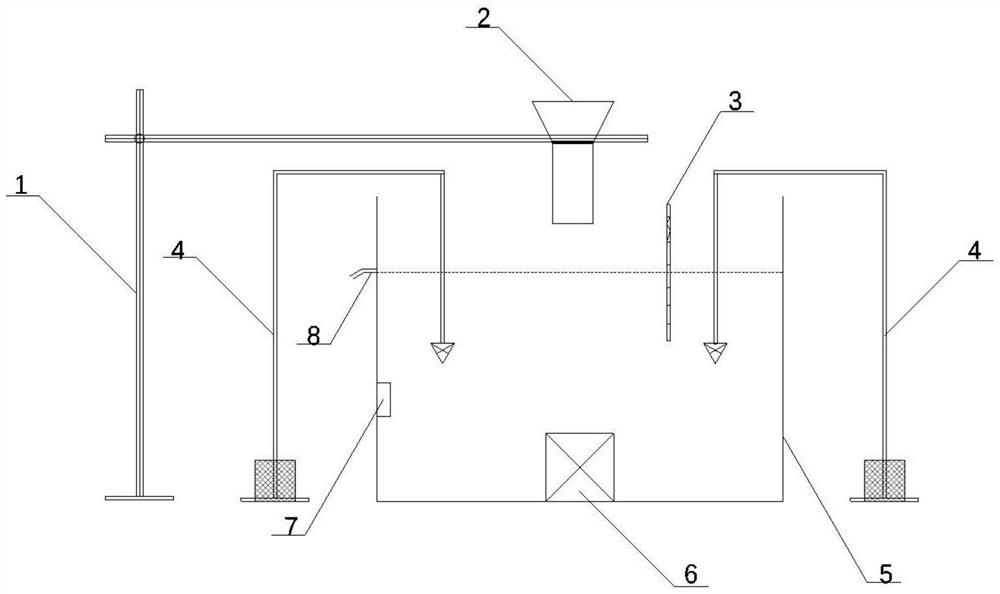

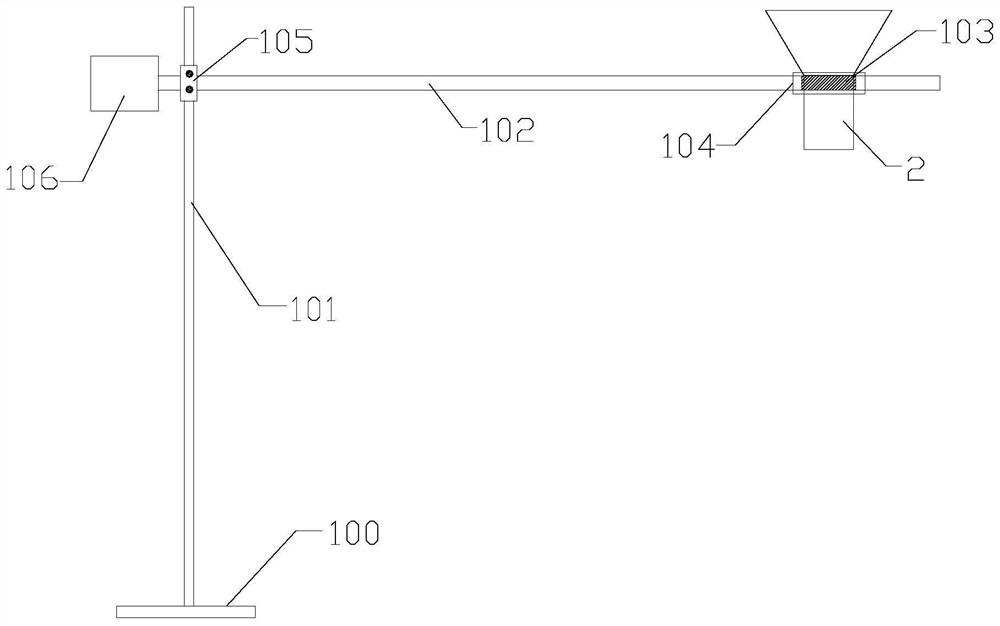

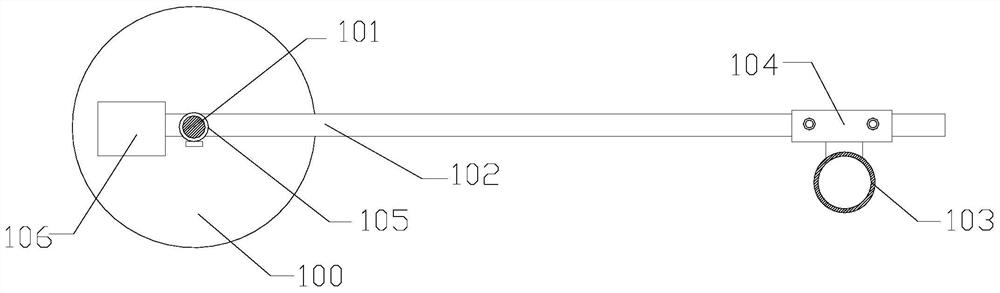

System and method for testing performance of underwater non-dispersible slurry in water conservancy and hydropower engineering

A technology of water conservancy, hydropower and testing system, which is applied in the direction of applying stable tension/pressure to test the strength of materials, preparation of test samples, and analysis of materials, etc. Problems such as the effect of construction application and the inability to adjust according to actual needs, etc., to achieve a scientific and reasonable effect of the test plan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1 Aiming at an underwater project that requires the use of underwater non-dispersible clean slurry for on-site seepage plugging, after analysis and research, the project’s design indicators and requirements for the plugging slurry: the suspension of the water body after adding the underwater non-dispersible slurry The turbidity content is ≤50mg / L, the pH value is ≤8.5, the underwater expansion is controlled at 180mm±10mm, and the final setting is within 5 hours. The project is located about 3m underwater, the water temperature is about 15°C, and the water velocity is small, so it can be regarded as a still water state. In view of the above performance requirements, the cement slurry is basically selected to seal the leakage of the project, but how to determine that the performance of the cement slurry meets the above performance requirements, the existing methods cannot be simulated for the project site, so the project engineers The above-mentioned test device i...

Embodiment 2

[0058] Example 2 For an underwater project that needs to be repaired with underwater non-dispersible mortar, the repaired part is 5m underwater, there is a certain water flow, and the underwater temperature is about 25°C; there are two kinds of sand-containing cement-based materials to choose from. The properties of the two materials are compared and optimized. The materials are required to remain undispersed underwater, self-flowing (the degree of expansion is required to be controlled within the range of 180mm±10mm), and have a certain strength (28d underwater compressive strength is greater than 20MPa), and 7d, 28d The land-water intensity ratio is not less than 70%.

[0059] For this reason, by simulating the field conditions, the related performance tests of two materials (A1, A2) underwater non-dispersible mortar were compared to evaluate the material performance.

[0060] (1) Fill the water tank with water so that the water surface remains flush with the overflow hole 8...

Embodiment 3

[0072] Example 3 is an embankment project. There is a leak at 6m underwater in the embankment project, causing the downstream surface to flow soil. It needs to be repaired with underwater non-dispersible concrete. The repaired part has a relatively large water velocity and the underwater temperature is about 10°C. The underwater non-dispersible concrete is required to be non-dispersible underwater, the content of underwater suspended matter ≤ 100mg / L, the pH value ≤ 9.0, the degree of underwater expansion should be controlled at 490mm±10mm, and the defect can be blocked within 4 hours (the final time within 240min) condensation).

[0073] For this reason, three kinds of concrete flocculants (B1, B2, B3) were selected for comparison, and by simulating the field conditions, the relevant performance tests of underwater non-dispersible concrete were carried out for engineering reference.

[0074] (1) Fill the water tank with water so that the water surface is flush with the overfl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com