Nano-film tensile test instrument and tensile test method

A nano-film and experimental instrument technology, which is applied in the direction of laboratory stools/lab tables, instruments, scientific instruments, etc., can solve the problem of inability to measure the tensile curve of nano-film materials, so as to reduce non-experimental losses and reduce experimental costs , The effect of simple test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that the following detailed description is exemplary and intended to provide further explanation of the present disclosure. Unless otherwise defined, all technical and scientific terms used in this disclosure have the same meaning as commonly understood by one of ordinary skill in the art to which this disclosure belongs.

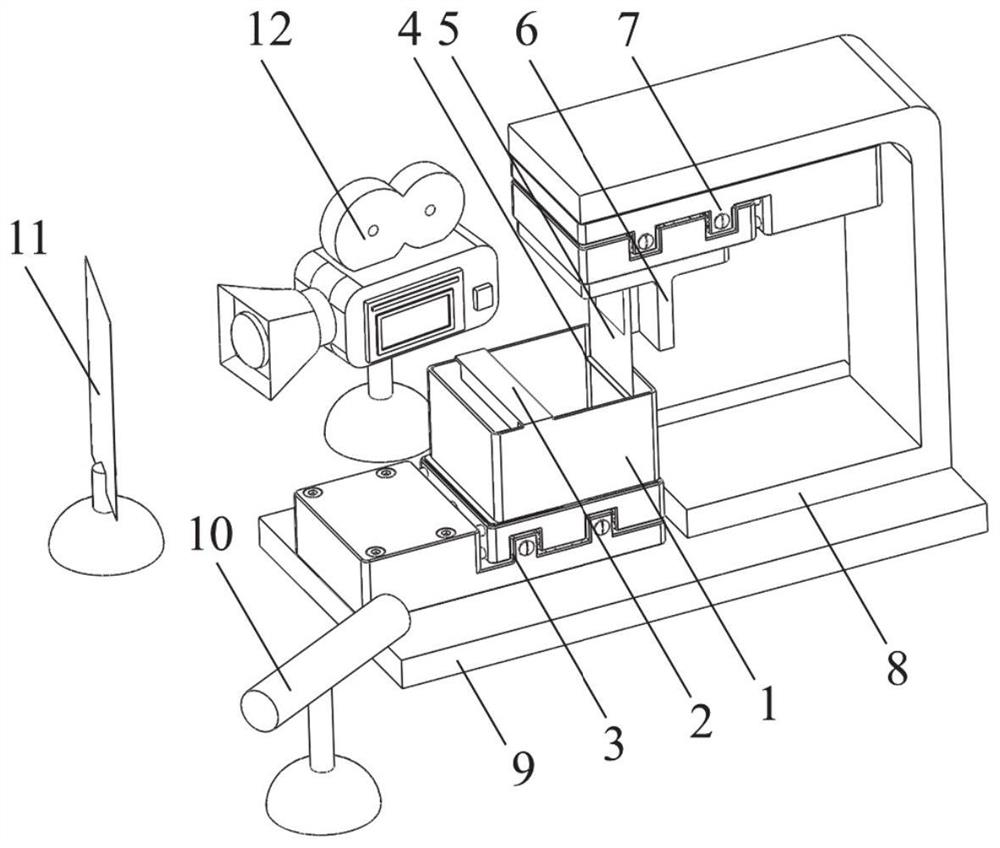

[0035] like figure 1 As shown, the embodiment of the present disclosure provides a novel nano-film tensile experimenter, which mainly includes a loading part, a positioning part and a laser testing part.

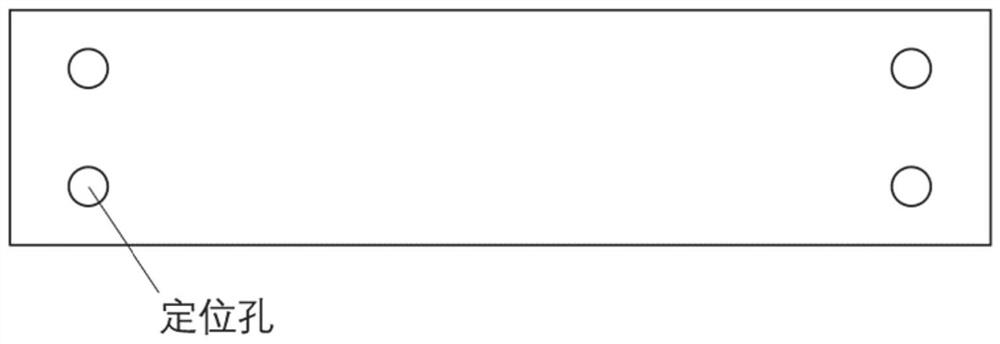

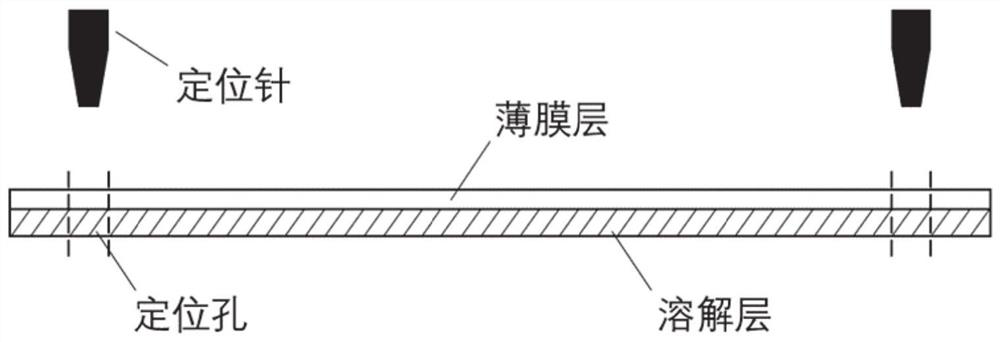

[0036] Specifically, as Figure 4 As shown, the loading part mainly includes a bottom plate 9 , a nanometer loading stage 3 and a liquid reservoir 1 . The bottom plate is a rectangular bottom plate, a nano-loading table 3 is provided at one end of the rectangular bottom plate, and a liquid storage tank 1 is installed on the top of the nano-loading table 3, and the liquid storage tank 1 is a rectangle with an open top. The liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com