Rapid thermal calibration device for Pin Fin substrate

A technology of thermal calibration and substrate, which is applied in the direction of measuring devices, electric devices, and thermometers using electric/magnetic elements that are directly sensitive to heat, can solve problems such as inaccurate measurement, shorten calibration time, reduce volume, Effect of Improving Calibration Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

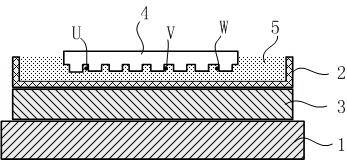

[0017] Example 1, such as figure 1 A rapid thermal calibration device for Pin Fin substrates shown includes an electromagnetic heating plate 1, an iron plate 3 is arranged between the electromagnetic heating plate 1 and the tank body 2, and the upper surface of the iron plate 3 is in contact with the groove body The lower surface of the body 2 abuts, and the lower surface of the iron plate 3 abuts against the upper surface of the electromagnetic heating plate 1 .

[0018] The tank body 2 is an aluminum tank with a depth of 20 mm. The tank body 2 is covered with fine sand 5, and the Pin Fin substrate 4 to be measured is buried in the fine sand 5.

[0019] How to use this device:

[0020] First, fill the aluminum tank body 2 with a depth of 20mm with fine sand, pave the fine sand, fully wet the sand with pure water, and press the Pin Fin substrate IGBT 4 into the water-containing sand.

[0021] Then extend three thermocouples along the shell surface of the Pin Fin substrate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com