Lithium ion battery matching method

A lithium-ion battery, matching technology, applied in the field of lithium-ion batteries, can solve the problems of battery parameter difference, insufficient battery parameters and battery influence weight, etc., to achieve the effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

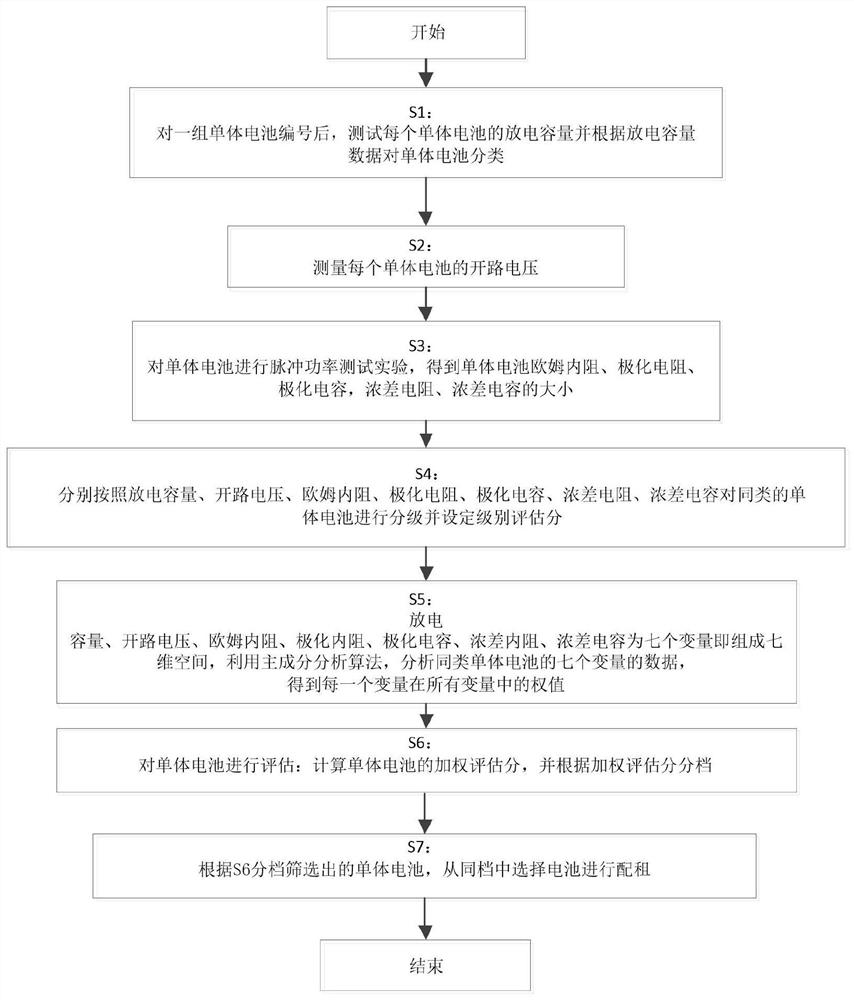

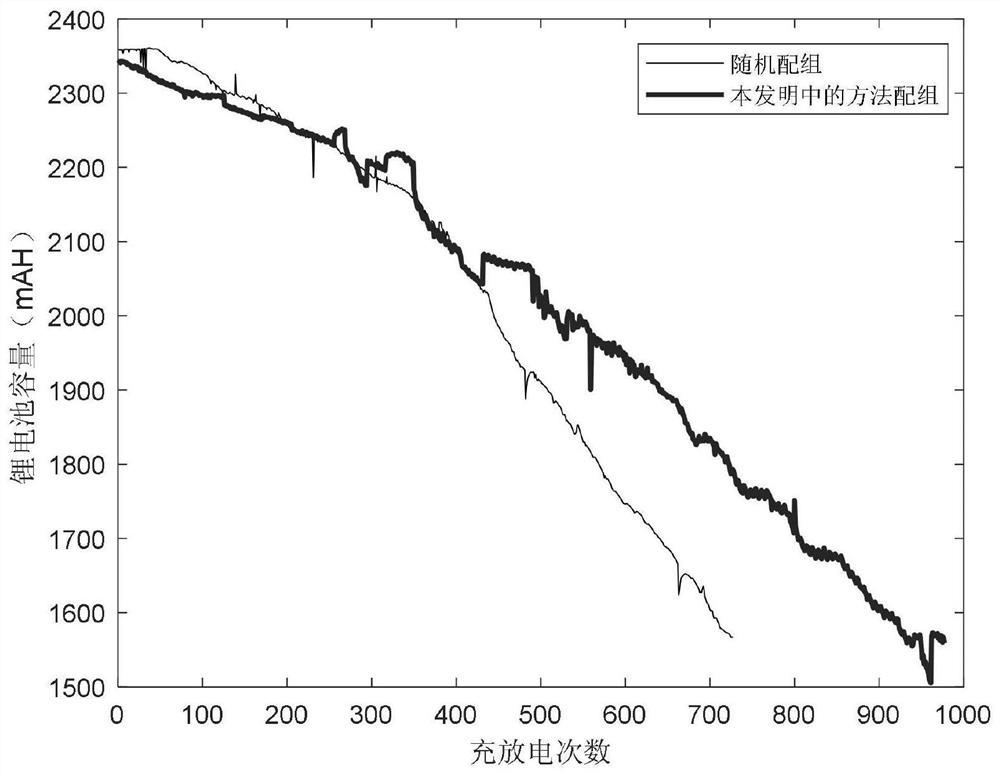

[0089] It is set to select 6 lithium-ion power batteries from 30 18650 lithium-ion power batteries with a rated capacity of 2400mAh for series matching. The specific steps of the matching method are as follows:

[0090] (1) Number the single batteries from 01 to 30, use the charging and discharging equipment to discharge the single batteries three times with a discharge current of 1800mA, record the average discharge capacity, and perform pre-classification after obtaining the discharge capacity of each single battery , which are divided into four categories, namely, the first category 2448mAh~2496mAh, the second category 2400mAh~2448mAh, the third category 2352mAh~2400mAh, and the fourth category 2304mAh~2352mAh;

[0091] (2), put the single battery on hold for 10 minutes, and measure the open circuit voltage of the battery;

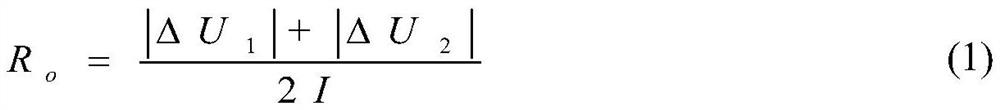

[0092] (3), HPPC test is carried out on the battery: the value of the discharge current is the actual discharge capacity obtained in step (1), discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com