A thermodynamic performance analysis and optimization system for a power plant

A technology for thermal performance and power plants, applied in the field of power systems, can solve problems such as lack of power, weak data processing capabilities, real-time monitoring of equipment thermal performance and poor fault diagnosis capabilities, etc., to achieve the effect of ensuring authenticity, accurate calculation, and powerful functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

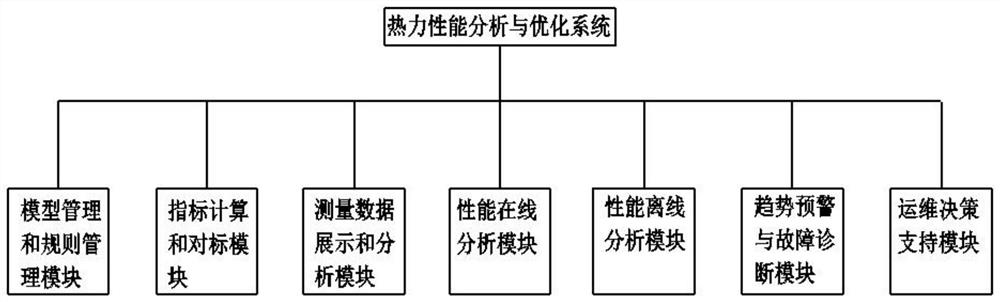

[0030] Embodiment: a thermodynamic performance analysis and optimization system of a power plant.

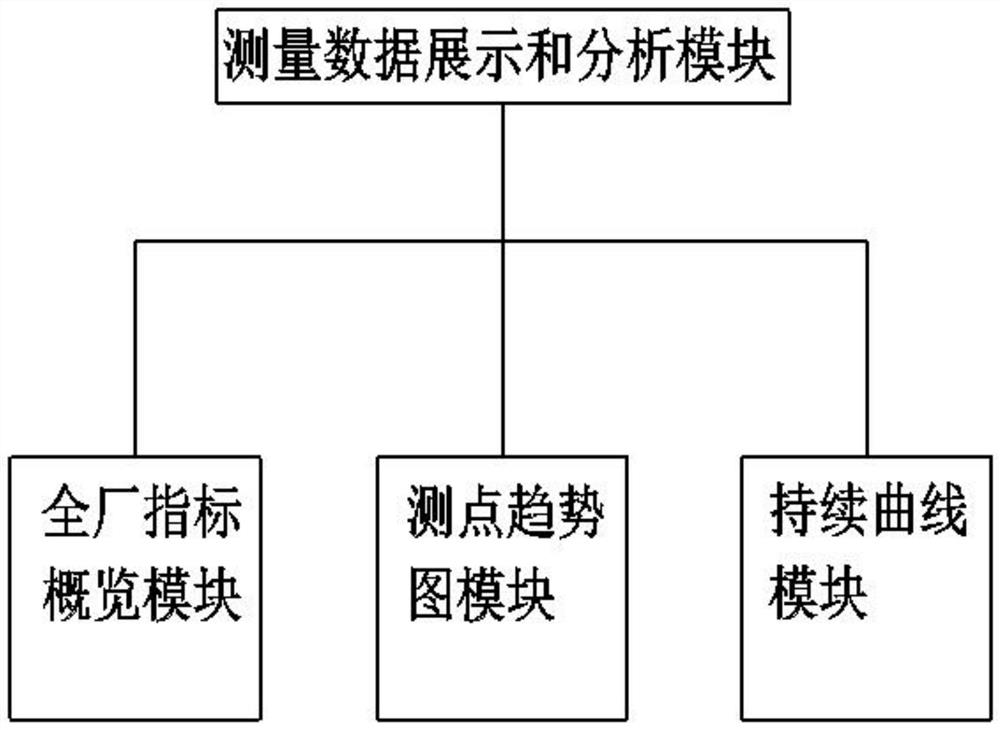

[0031] refer to Figure 1 to Figure 5 As shown, a thermodynamic performance analysis and optimization system of a power plant takes the thermodynamic model as the core, establishes a performance analysis model according to equipment characteristics and system logic, and uses real-time, historical operation data and simulation data of the thermal model to carry out equipment and system optimization. Economic analysis, diagnosis and forecasting provide owners with decision-making support for operation mode and technical improvement, and ultimately help power plants, units and equipment maintain their high performance levels. This thermal performance analysis and optimization system includes the following modules:

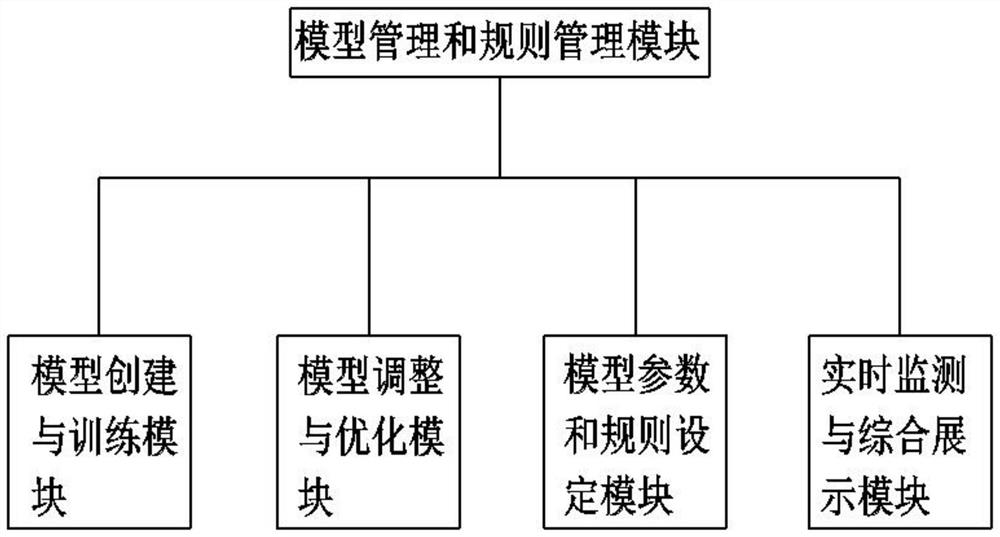

[0032] (1) Model management and rule management module: used to establish models for important equipment or systems of gas turbine units, and use a large number of on-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com