Device and method for vertically clamping seedlings of kelp in rows

A technology for clamping seedlings and kelp, which is applied in the field of fishery equipment, can solve the problems of large root system development, difficulty in ensuring reliability, and complex structure of kelp seedlings, and achieve the effects of improving the success rate, facilitating replication, and improving the survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

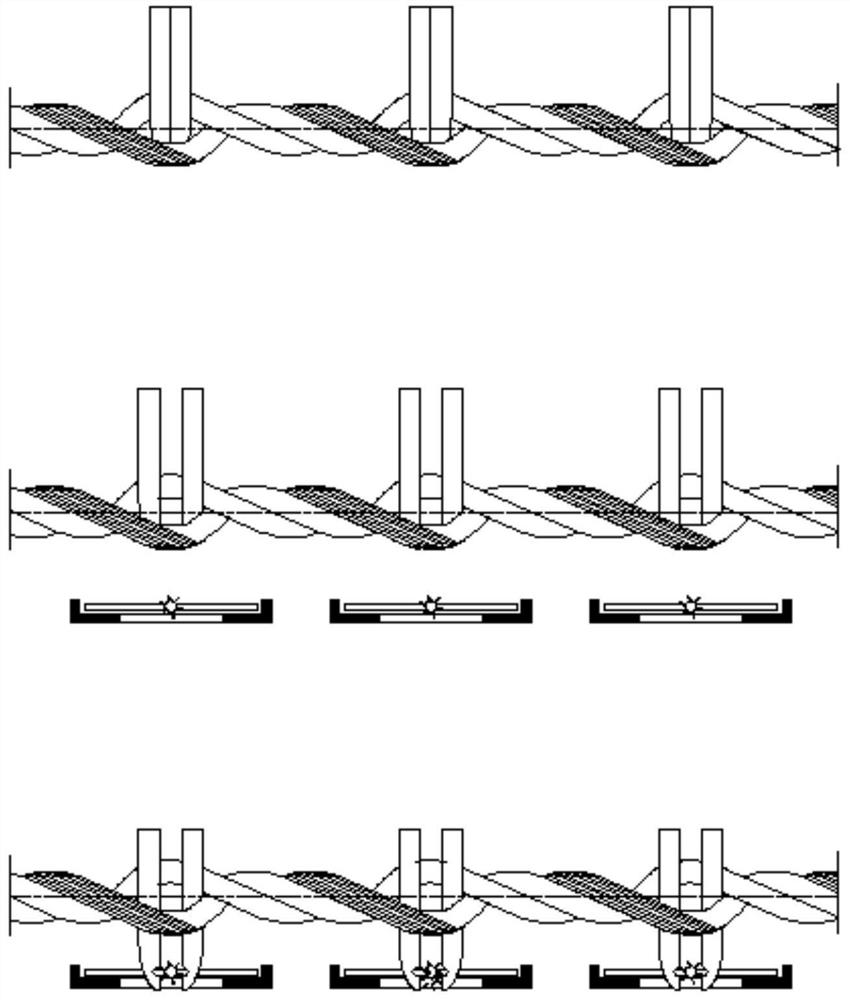

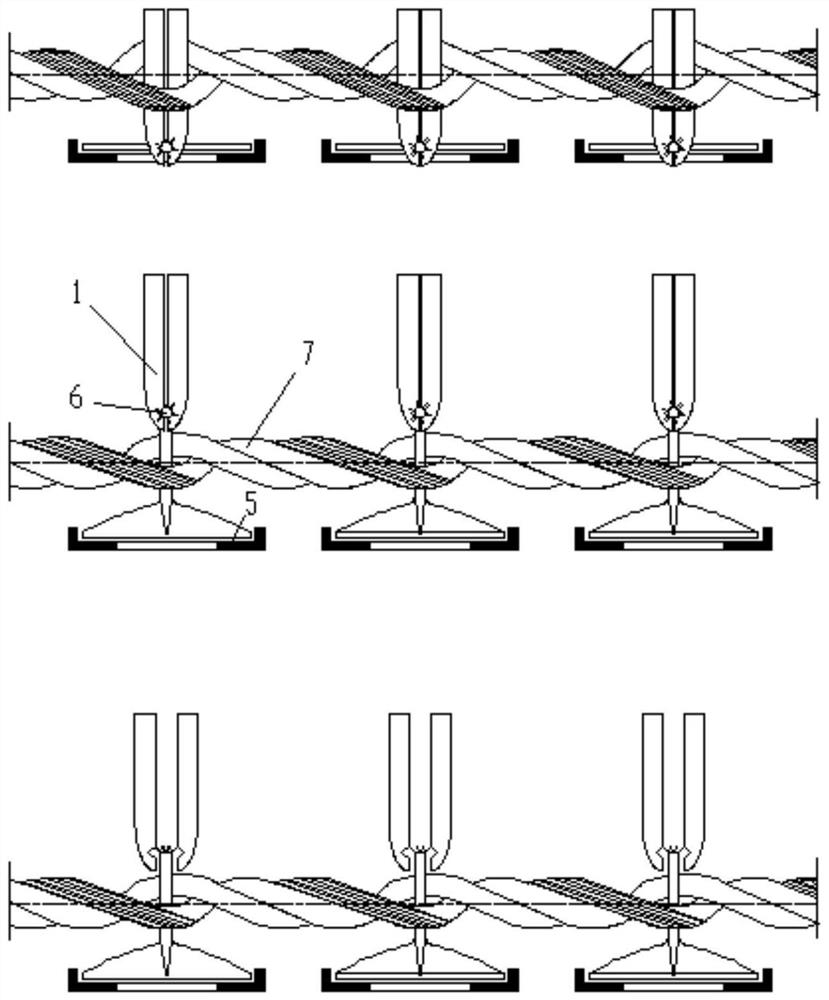

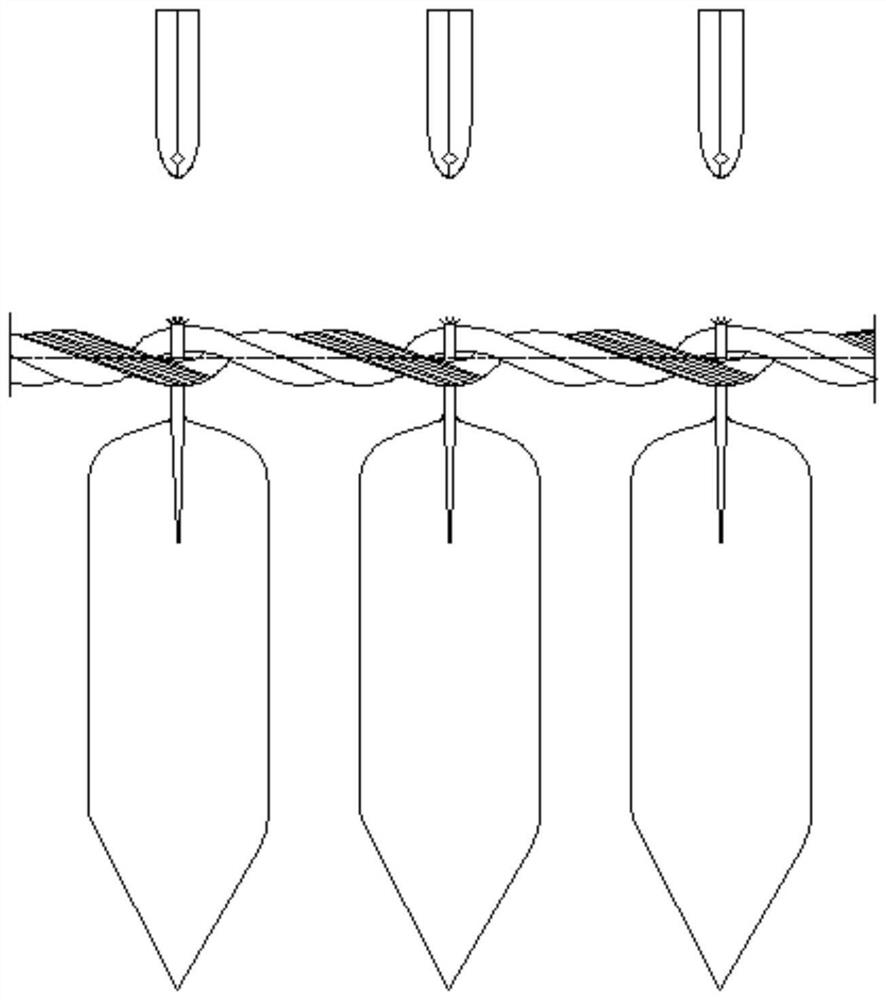

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0039] see Figure 1-15 , the kelp vertical clamping device in rows is provided with a clamping device 1, a clamping device insertion mechanism 2, a clamping device opening and closing mechanism 3, an unrotating device 4, a seedling box 5, kelp seedlings 6, seedling ropes 7, and a servo motor 8 , Gear 9, active rack 10, spring 11, oscillator 12, guide rail 13, auxiliary pressing device 14, finger cylinder 15, clip seedling device finger 16, strip plate 17, etc. The seedling clamping device 1 is composed of left and right seedling clamping fingers 16, which are ellipsoidal when the ends of the fingers are closed, and are convenient to be inserted into the gaps of the three interwoven seedling ropes 7. The square or hexagonal hole is used to accommodate the cylindrical root handle, which is not easy to fall when clamping; the inner square or hex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com