Production method of ethyl trifluoroacetoacetate

A technology of ethyl trifluoroacetoacetate and ethyl fluoroacetoacetate, which is applied in the production field of ethyl trifluoroacetoacetate, can solve the problems of inability to realize foam recovery, poor flexibility of defoaming structure, and inability to self-adapt adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033]The invention provides a production method of ethyl trifluoroacetoacetate. The production method of ethyl trifluoroacetoacetate is completed by a production device of ethyl trifluoroacetoacetate, thereby realizing the high yield of ethyl trifluoroacetoacetate efficient production;

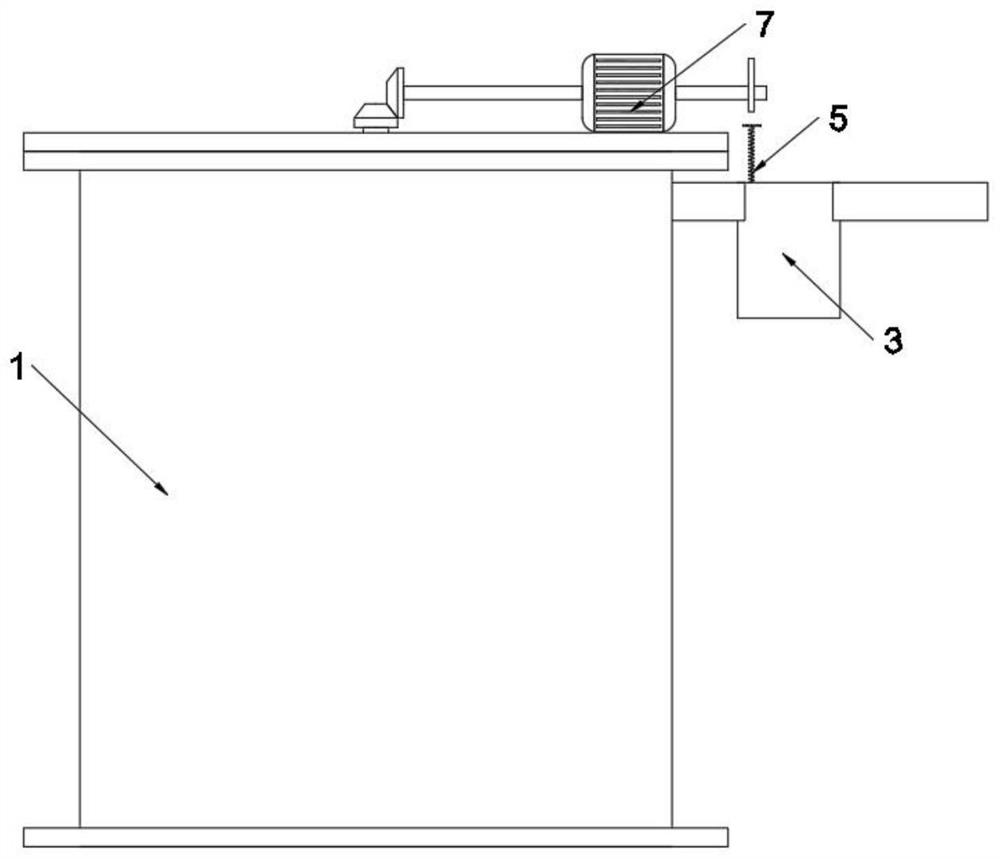

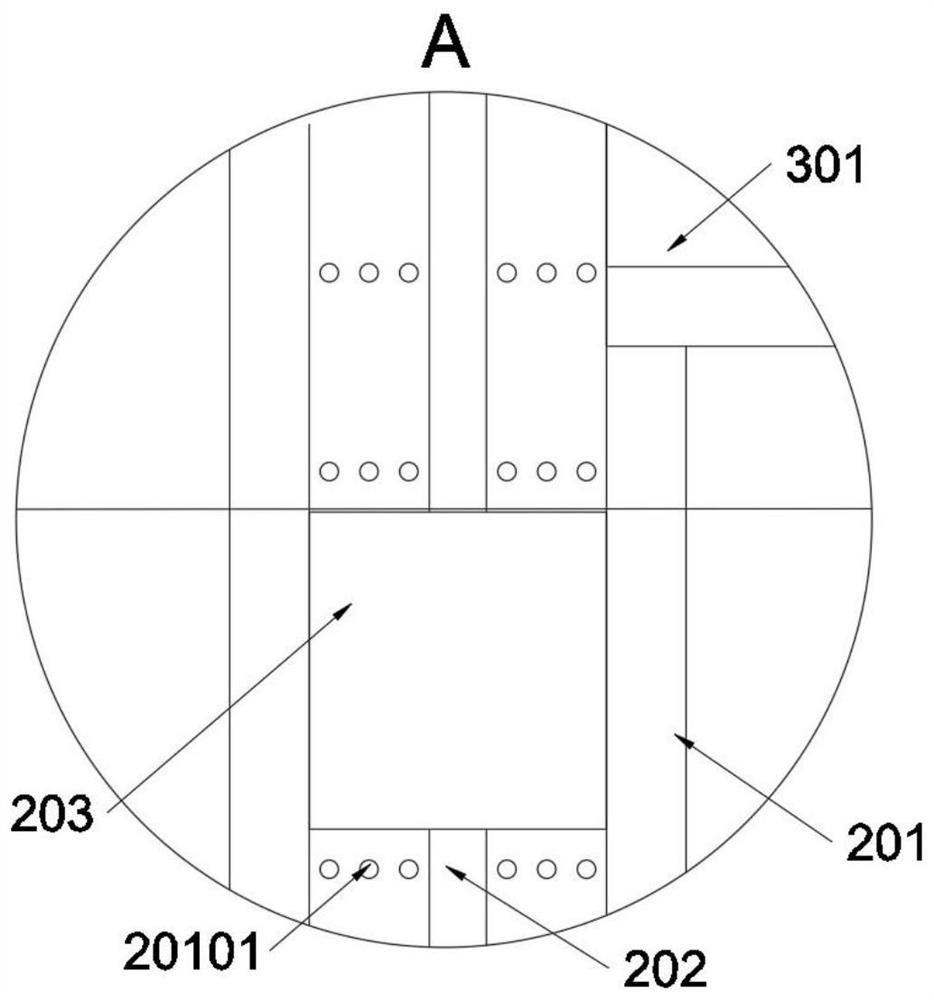

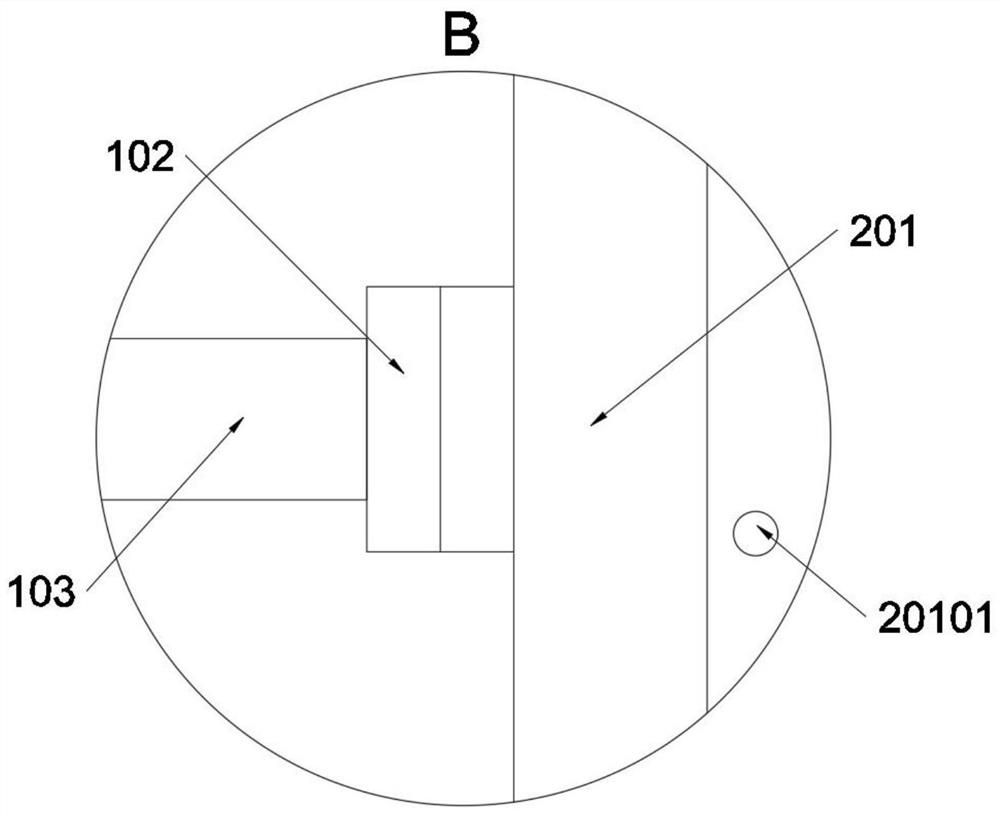

[0034] The production device of the ethyl trifluoroacetoacetate comprises a barrel body 1; a defoaming structure 2 is installed on the barrel body 1, and an absorption structure 3 is also installed on the barrel body 1, and an auxiliary structure 4 is installed on the absorption structure 3; A cleaning structure 5 is installed on the absorption structure 3; a mixing structure 6 is rotatably connected to the barrel body 1, and a driving structure 7 is installed on the barrel body 1; refer to as figure 2 and Figure 4 The defoaming structure 2 includes a suction pipe 201 and a suction hole 20101, the suction pipe 201 is a cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com